Sodium ion battery negative electrode material and preparation method thereof

A sodium-ion battery and negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as general structural stability, low electronic conductivity, and poor cycle performance, and achieve improved structural stability and electrical conductivity. Improve the use effect and realize the effect of waste utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

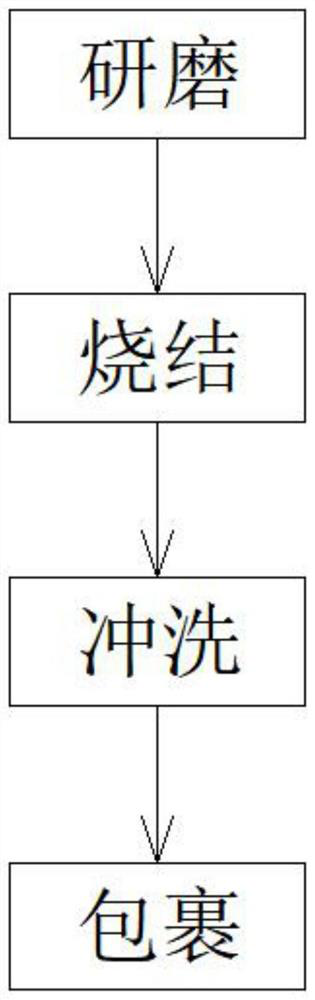

[0022] see figure 1 , the present invention provides a kind of technical scheme: a kind of its preparation method of sodium-ion battery negative electrode material, comprises the following steps:

[0023] Step 1: Put the potassium source, titanium source, lithium source and potassium molybdate into the mixing equipment for stirring and mixing fully, and then use the grinding equipment to grind them to obtain powder;

[0024] Step 2: Put the powder obtained in Step 1 into a platinum crucible, and then put it into a sintering furnace for sintering. The sintering time is 5 hours. After the sintering is completed, cool it down for use;

[0025] Step 3: repeatedly washing the product obtained in step 2 with boiling water, and then drying it with drying equipment to obtain lithium potassium titanate;

[0026] Step 4: mixing the carbon source with the product in step 3, and then introducing into a sintering furnace and sintering again for 2 hours to obtain carbon-wrapped lithium pot...

Embodiment 1

[0029] Take the same amount of potassium source, titanium source, lithium source and potassium molybdate into the mixing equipment for stirring and mixing fully, and then use the grinding equipment to grind it, the grinding is dry grinding, the grinding time is 2-3h, and the powdery Put the obtained powder into a platinum crucible, and then put it into a sintering furnace for sintering. The temperature condition of the sintering furnace is 1100°C, and the sintering time is 5h. After the sintering is completed, it is cooled to room temperature for use. The finished product is washed repeatedly, and then dried by drying equipment to obtain lithium potassium titanate. The carbon source is mixed with the dried lithium potassium titanate, and then introduced into the sintering furnace for sintering again for 2 hours. The temperature of the sintering furnace The condition is 600°C to obtain carbon-wrapped lithium potassium titanate;

[0030] The material obtained in Example 1 was us...

Embodiment 2

[0032] Take the same amount of potassium source, titanium source, lithium source and potassium molybdate into the mixing equipment for stirring and mixing fully, and then use the grinding equipment to grind it, the grinding is dry grinding, the grinding time is 2-3h, and the powdery Put the obtained powder into a platinum crucible, and then put it into a sintering furnace for sintering. The temperature condition of the sintering furnace is 1100°C, and the sintering time is 5h. After the sintering is completed, it is cooled to room temperature for use. The final product is washed repeatedly, and then dried by drying equipment to obtain lithium potassium titanate;

[0033] Then use the material obtained in Example 2 to make negative electrode material and test its electrochemical performance.

[0034] The performance test results are as follows:

[0035] circularity Conductivity Storage capacity Embodiment one high high high Embodiment two Low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com