Method for preparing CoFe-PBA@PVDF composite membrane by combining coordination self-assembly with delayed phase change and application of CoFe-PBA@PVDF PVDF composite membrane

A technology of self-assembly and composite membranes, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of uneven distribution of inorganic nanoparticles, membrane pollution, etc., achieve excellent antifouling performance, solve poor compatibility, good The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] PVDF 4.2g, PVP 0.1g, Co(NO 3 ) 2 ·6H 2 O 1g, DMAC with a volume of 30mL of casting solution was stirred evenly at 50°C, then left to remove air bubbles, scraped the film with a 200μm film scraper on a flat-panel film scraper, and quickly put potassium ferricyanide at a concentration of 30mg / mL, in a coagulation bath with DMAC:Water ratio of 1:4, phase inversion is achieved at room temperature. After the membrane is formed and the coordination of the surface inorganic particles is completed, the excess coagulation bath liquid on the surface and the unstable Prussian blue analog (PBA) on the surface are washed with deionized water, and soaked in deionized water for 12 hours to obtain CoFe-PBA@ The PVDF composite membrane is marked as M4.

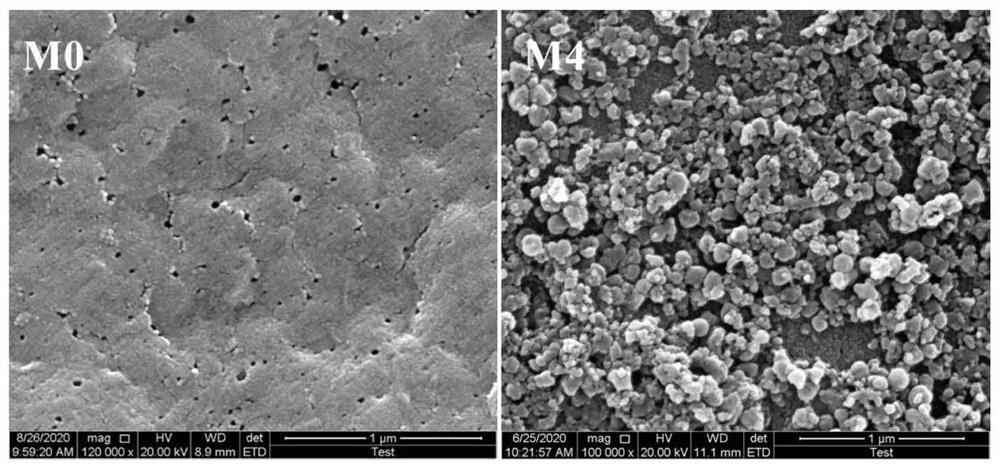

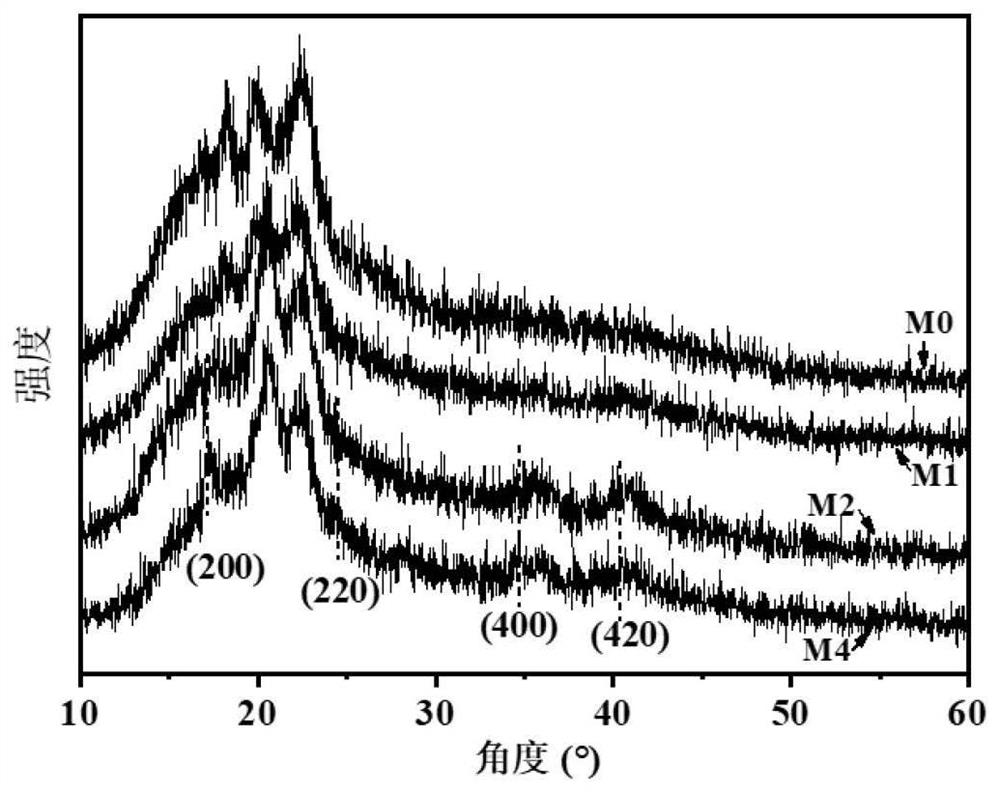

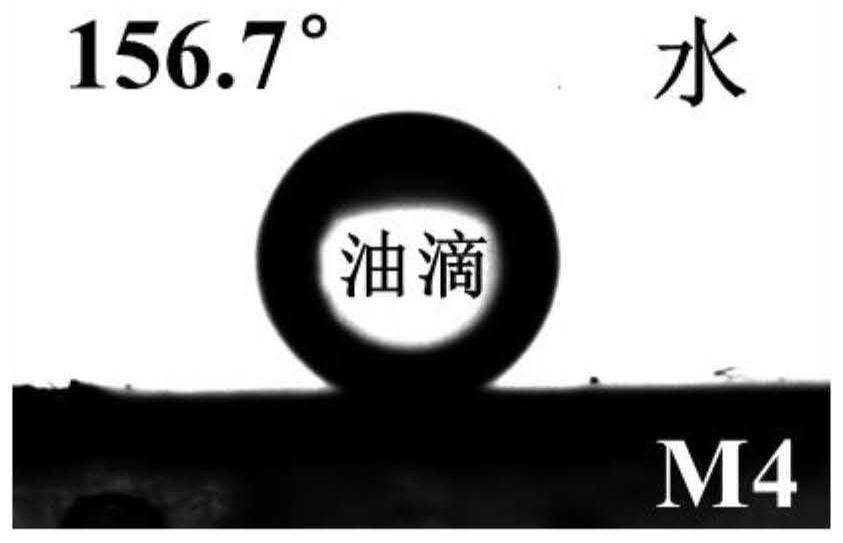

[0028] The surface morphology characteristics of the prepared CoFe-PBA@PVDF composite film and the quartz film before modification were observed by scanning electron microscope (SEM). figure 1 is the SEM image of the prepared membr...

Embodiment 2

[0032] PVDF 4.2g, PVP 0.1g, Co(NO 3 ) 2 ·6H 2 O 0.5g, DMAC with a volume of 30mL of casting solution is stirred evenly at 50°C, and then left to remove air bubbles, scrape the film with a 200μm scraper on a flat-panel film scraper, and quickly add potassium ferricyanide at a concentration of 30mg / mL, in a coagulation bath with DMAC:Water ratio of 1:4, phase inversion is achieved at room temperature. After the membrane is formed and the coordination of the surface inorganic particles is completed, the excess coagulation bath liquid on the surface and the unstable Prussian blue analog (PBA) on the surface are washed with deionized water, and soaked in deionized water for 12 hours to obtain CoFe-PBA@ The PVDF composite membrane is marked as M3.

Embodiment 3

[0034] PVDF 4.2g, PVP 0.1g, Co(NO 3 ) 2 ·6H 2 O 1.5g, DMAC with a volume of 30mL of casting solution is stirred evenly at 50°C, then let it stand to remove air bubbles, scrape the film with a 200μm scraper on a flat-panel film scraper, and quickly add potassium ferricyanide at a concentration of 30mg / mL, in a coagulation bath with DMAC:Water ratio of 1:4, phase inversion is achieved at room temperature. After the membrane is formed and the coordination of the surface inorganic particles is completed, the excess coagulation bath liquid on the surface and the unstable Prussian blue analog (PBA) on the surface are washed with deionized water, and soaked in deionized water for 12 hours to obtain CoFe-PBA@ The PVDF composite membrane is marked as M5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com