Coating material and preparation method thereof

A coating and liquid material technology, applied in the field of flame retardant coatings and their preparation, can solve the problems of poor thermal insulation effect, long-term comprehensive effect of flame retardant effect, inability to lasting stable protection, short service life, etc., and achieve comprehensive stability. Good protection, long-term stable adhesion, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The ratio in parts by weight and the preparation method between the raw materials are as follows:

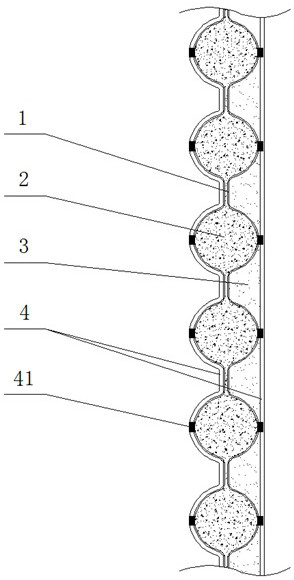

[0043] The coating in the coating layer 2, the raw materials of the weight ratio of the coating include: 20-29 parts of polymethyl methacrylate powder, 15-22.5 parts of ceramic closed-cell microbeads, 2-5 parts of infrared reflector, acrylic acid 8-15 parts of nano-microemulsion, 1-5 parts of pigment, 0.3-1.5 parts of thickener, 0.7-2 parts of auxiliary agent, 1 part of light magnesium oxide powder; the particle size of the polymethyl methacrylate powder is 1-10 μm; the ceramic closed-cell microspheres are made of silicon nitride, alumina, zirconia, and coal gangue hollow microspheres, and the particle size of the ceramic closed-cell microspheres is 10-100 μm; the infrared reflection The agent includes nano-titanium dioxide and aluminum silicate fiber, and the nano-titanium dioxide and aluminum silicate fiber are mixed according to a weight ratio of 1: (0.5~1). The nano-t...

Embodiment 2

[0045] The bottom liquid material in the bottom liquid material layer 3, the raw materials of the weight ratio of the bottom liquid material include: 6~10 parts of titanium dioxide powder, 1~6 parts of airgel particles, 5~10 parts of acrylate adhesive emulsion part; the titanium dioxide powder can be 20-50nm in the same material and particle size as the nano-titanium dioxide; the airgel particles can be silica airgel powder, and the particle size can be 30-60nm; the acrylate The adhesive emulsion may be an emulsion type acrylate adhesive. The preparation method of the bottom liquid material in the bottom liquid material layer 3 is as follows: the titanium dioxide powder, the airgel particles, and the acrylate adhesive emulsion are in another mixing mixer according to the ratio of parts by weight, After stirring at a speed of 1000r / min for 20-30min, the bottom liquid material was obtained and produced. In an embodiment, as the amount of airgel particles increases, the heat tra...

Embodiment 3

[0047] The coating in the coating layer 2 can also be made by the following method: 20 parts of polymethyl methacrylate powder, 15 parts of silicon nitride ceramic closed-cell microspheres, 1 part of nano titanium dioxide, 1 part of aluminum silicate fiber, 1 part Iron oxide red pigment, 1 part of light magnesium oxide powder, 0.5 part of thickener plus 100 parts of water are put into a ball mill and milled for 30 minutes to obtain a mixed slurry; transfer the mixed slurry to a mixing mixer and add 15 parts of acrylic acid nano-microemulsion , 0.3 part of defoamer, 0.5 part of dispersant, and stirred at a speed of 1000r / min for 40min to obtain the thermal insulation coating.

[0048] In the embodiment, 20 parts of polymethyl methacrylate powder, 15 parts of alumina ceramic closed-cell microspheres, 2 parts of nano-titanium dioxide, 1 part of aluminum silicate fiber, 3 parts of iron oxide yellow pigment, 0.8 part of thickener Add 100 parts of water into the ball mill and mill f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com