Purification method and equipment, mixture flow treatment method and device, method for preparing epoxide and epoxidation reaction system

A purification method and epoxide technology, which are used in metal/metal oxide/metal hydroxide catalysts, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problem of affecting product quality and increasing impurity content of propylene oxide products, etc. problem, to achieve the effect of extending the service life of one-way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0091] In one embodiment (hereinafter referred to as "the first embodiment"), the separation step includes a first rectification and a second rectification,

[0092] In the first rectification, the liquid phase stream containing alcohol and / or the adjustment stream (when the adjustment step is performed, it is the adjustment stream; when the adjustment step is not performed, it is the alcohol-containing liquid phase stream) in In the first rectification tower, the first rectification is carried out under the first rectification pressure, the first distillate containing alcohol is obtained from the top of the first rectification tower, and the first tower bottom containing alcohol and water is obtained from the bottom of the tower logistics;

[0093] In the second rectification, the first bottom stream is subjected to the second rectification in the second rectification tower under the second rectification pressure, and the second rectification containing alcohol is obtained fr...

Embodiment 1

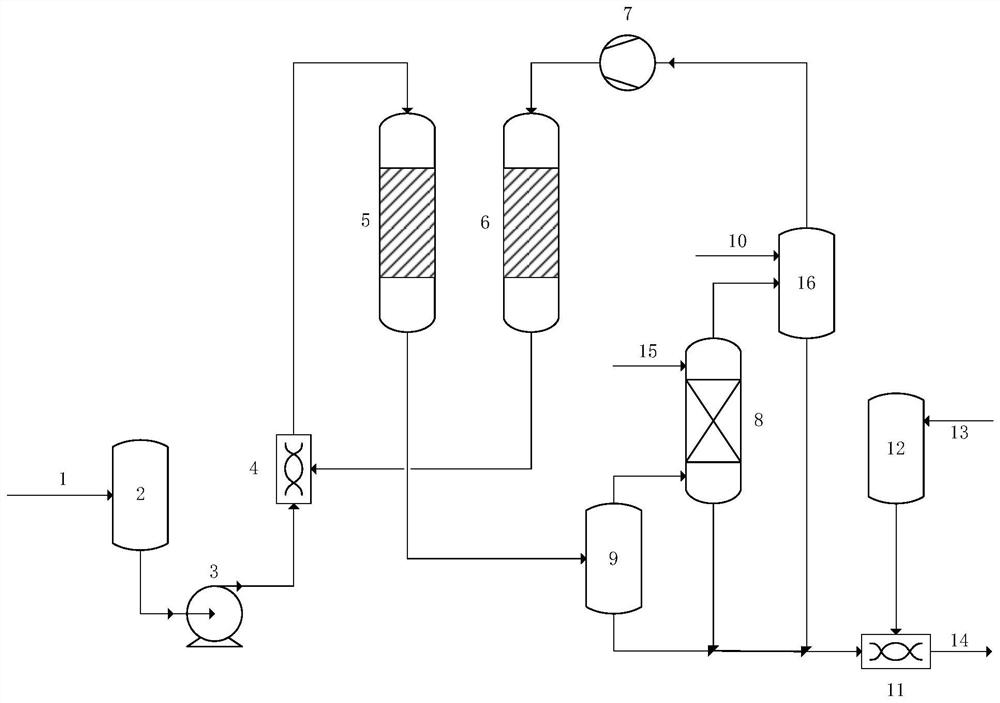

[0175] This embodiment adopts figure 1 The processing method shown processes a mixture stream consisting of:

[0176]Based on the total amount of the mixture stream, it contains 82.38% by weight methanol, 16.07% by weight water, 1100ppmw aldehyde, 3300ppmw hydrogen peroxide, 3ppmw propylene oxide, 8ppmw hydrazine, 9ppmw ammonia, 5ppmw hydrazone, and the balance is other impurities.

[0177] The preparation method of the catalyst with hydrogenation catalysis that present embodiment adopts is as follows:

[0178] In the reactor, add 20kg water, add 4.5kg pseudo-boehmite powder (production of Changling Catalyst Factory, solid content is 69.5% by weight, gamma-Al 2 o 3 content not less than 98% by weight), stir and mix evenly; add 200g concentrated hydrochloric acid (Sinopharm Chemical Reagent Co., Ltd., concentration is 36% by weight), mix and grind; add 2.3kg polyethylene glycol PEG4000 powder (Wenzhou Shuangxiao Rubber Plastic Materials Co., Ltd.), continue beating, stir and...

Embodiment 2

[0193] The mixed stream is treated in the same manner as in Example 1, and the recovered alcohol is used for the epoxidation reaction. The difference is that the reaction temperature of the hydrotreating reactor 5 is 70° C., the pressure is 0.8 MPag, and the liquid hour The volumetric space velocity is 1h -1 . The reaction temperature of the methanation reactor 6 is 90°C, the pressure is 1MPag, and the gas hourly volume space velocity is 1500h -1 , the experimental results are as follows:

[0194] (1) The carbon monoxide content in the outlet stream of the methanation reactor remains below 1 ppmw;

[0195] (2) The one-way service life of the catalyst with hydrogenation catalysis is 15 months;

[0196] (3) collect the composition of the methanol extracted from the first rectification tower and the second rectification tower, and determine that the purity of reclaimed methanol is more than 98% by weight;

[0197] (4) The purity of the propylene oxide product is 99.95% by wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com