Multifunctional benzoxazine composite material and preparation method thereof

A benzoxazine and composite material technology, which is applied in the field of new functional polymer materials, can solve the problems of high flammability and toughness of benzoxazine resin, and high temperature of ring-opening reaction, so as to improve the flame retardant performance and toughness, the process is simple, the The effect of reducing the rate of heat release and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

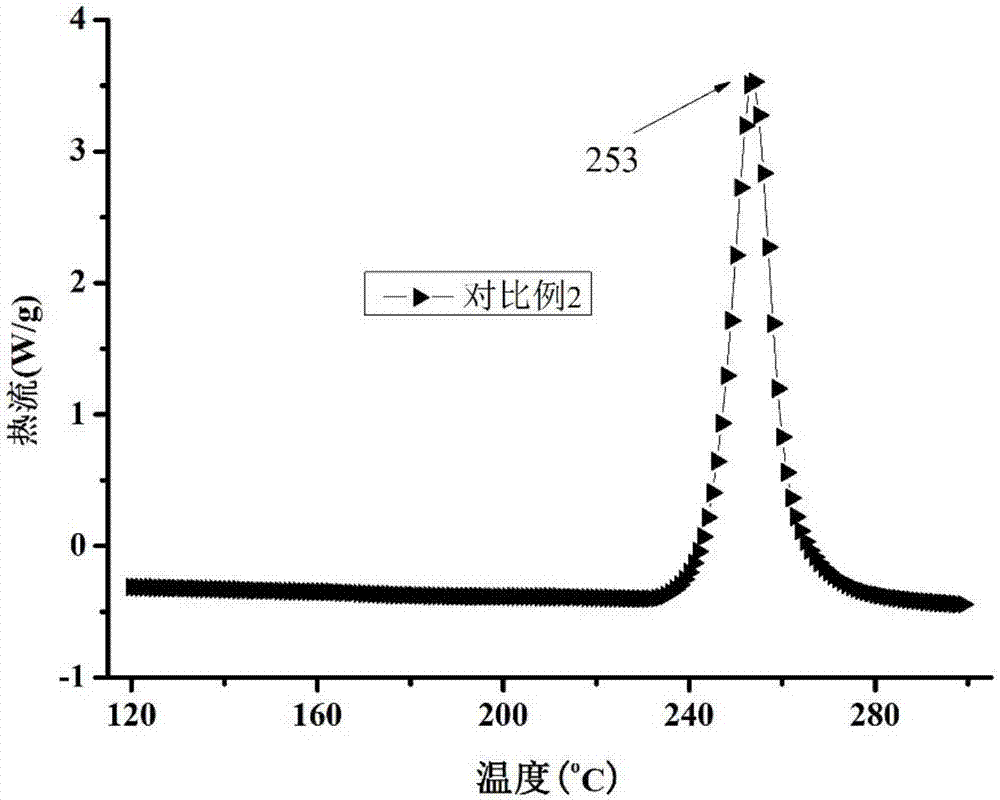

Embodiment 1

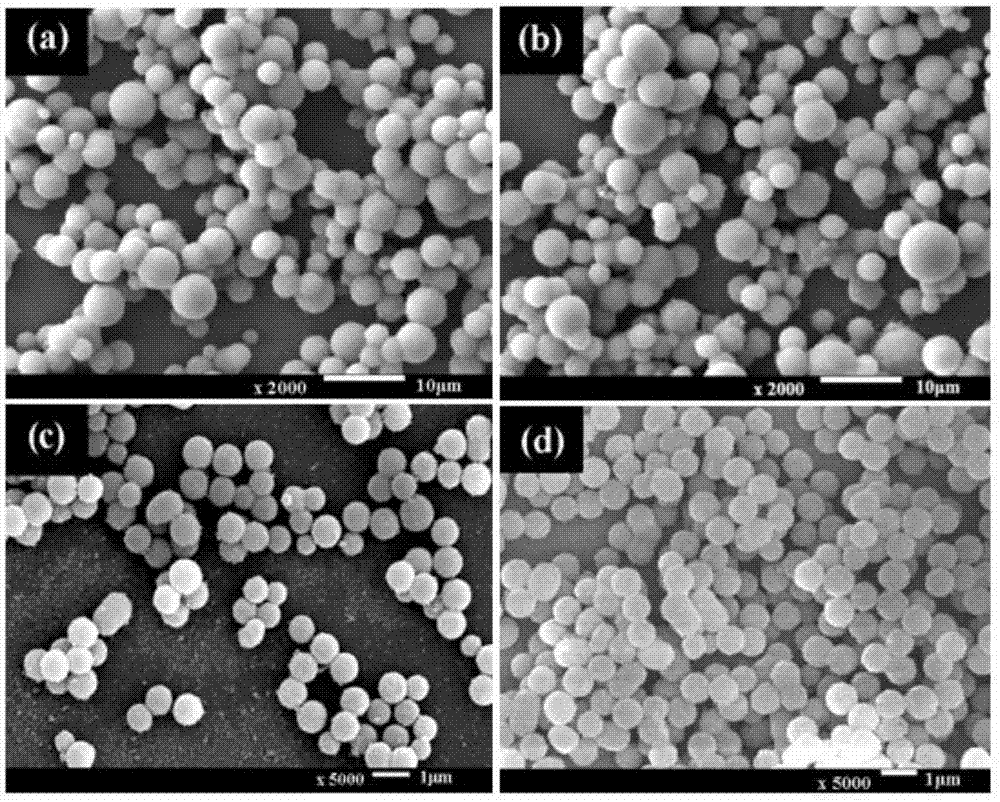

[0056] Preparation of cross-linked polyphosphazene solid microspheres: Weigh 60 parts of hexachlorotripolyphosphazene and 58 parts of hydroquinone, add them to 3000 parts of acetonitrile solvent, and ultrasonically disperse and mix evenly under the conditions of power 200W and frequency 40 Hz Finally, add 220 parts of acid-binding agent triethylamine; raise the temperature of the mixed reaction solution to 40°C, power 200W, and ultrasonically react at a frequency of 40 Hz for 4 hours; after the reaction solution is cooled to room temperature, centrifuge at a speed of 10,000rpm to obtain a yellow crude product; Using centrifugal cleaning method, the crude product was washed 4 times with acetone, deionized water and ethanol in sequence, and the purified product was placed in a vacuum oven and dried at 80°C for 8 hours to obtain a light yellow cross-linked polyphosphorus with an average particle size of 3um. Nitrile solid microspheres.

[0057] Preparation of sulfonated cross-lin...

Embodiment 2

[0060] Preparation of cross-linked polyphosphazene solid microspheres: Weigh 100 parts of hexachlorotripolyphosphazene and 217 parts of silicon-containing diamine (1,3-bis(3-aminopropyl)-1,1,3,3- Tetramethyldisiloxane), added to 1000 parts of acetone-acetonitrile mixed solvent with a volume ratio of 1:99, ultrasonically mixed at a power of 100W and a frequency of 20 Hz; then added 120 parts of N,N-dipropylene Base-1-propylamine, heat up to 60°C, ultrasonically react for 0.5h under the condition of power 100W, frequency 80 Hz, then stir the reaction at 400rpm at a constant temperature of 60°C for 8h, stop the reaction; after the reaction solution is cooled to room temperature, centrifuge at 3000rpm The white crude product was isolated; the crude product was washed three times with acetone, deionized water and ethanol successively by centrifugal cleaning method, and the purified product was placed in a vacuum oven and dried at 60°C for 4 hours to obtain a white product with an av...

Embodiment 3

[0064] Preparation of cross-linked polyphosphazene solid microspheres: Weigh 120 parts of hexachlorotripolyphosphazene and 93 parts of p-2-nitro-1,4-phenylenediamine, add them to 2500 parts of pyridine solvent, under the power of 300W, 100 Ultrasonic mixing under Hz conditions; then add 300 parts of N,N-dimethylaniline, heat up to 60°C, power 300W, and ultrasonically react at 100 Hz for 8 hours; after the reaction solution is cooled to room temperature, centrifuge at 15000rpm to obtain white Crude product; using centrifugal cleaning method, the crude product was washed 5 times with acetone, deionized water and ethanol in sequence, and the purified product was placed in a vacuum oven and dried at 90°C for 8 hours to obtain a white cross-linked structure with an average particle size of 0.2um Polyphosphazene solid microspheres.

[0065] Preparation of sulfonated cross-linked polyphosphazene solid microspheres: Weigh 5 parts of prepared cross-linked polyphosphazene solid microsph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com