Transparent flame-retardant benzoxazine nanocomposite material and preparation method thereof

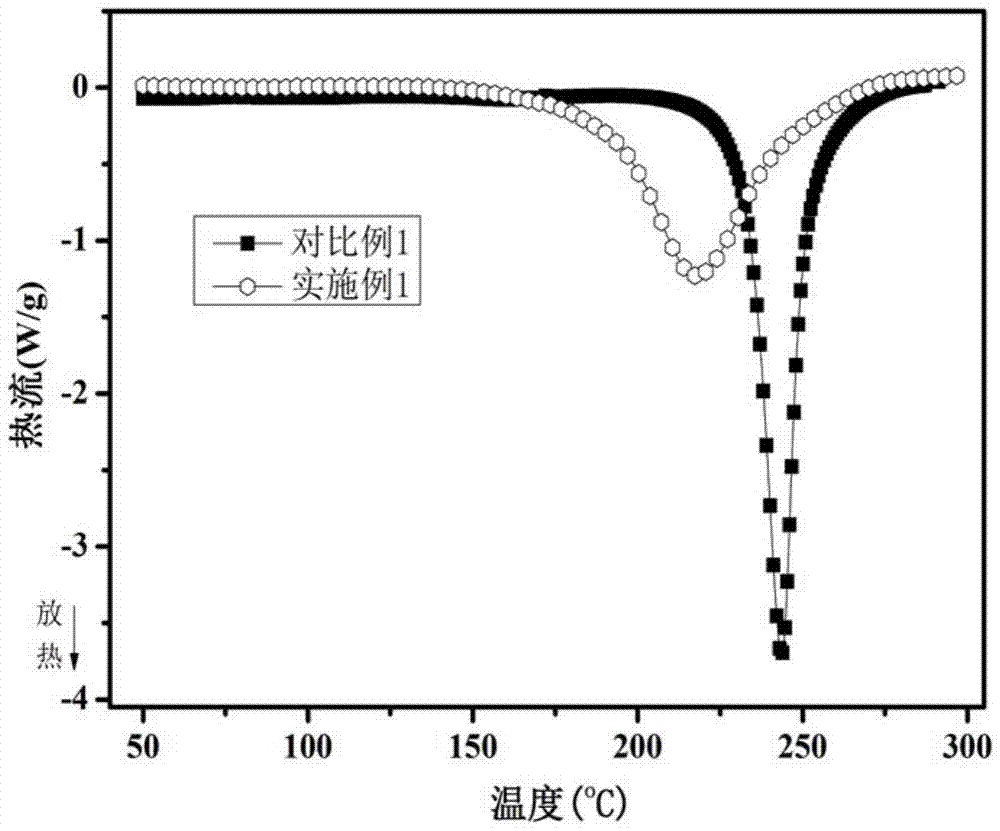

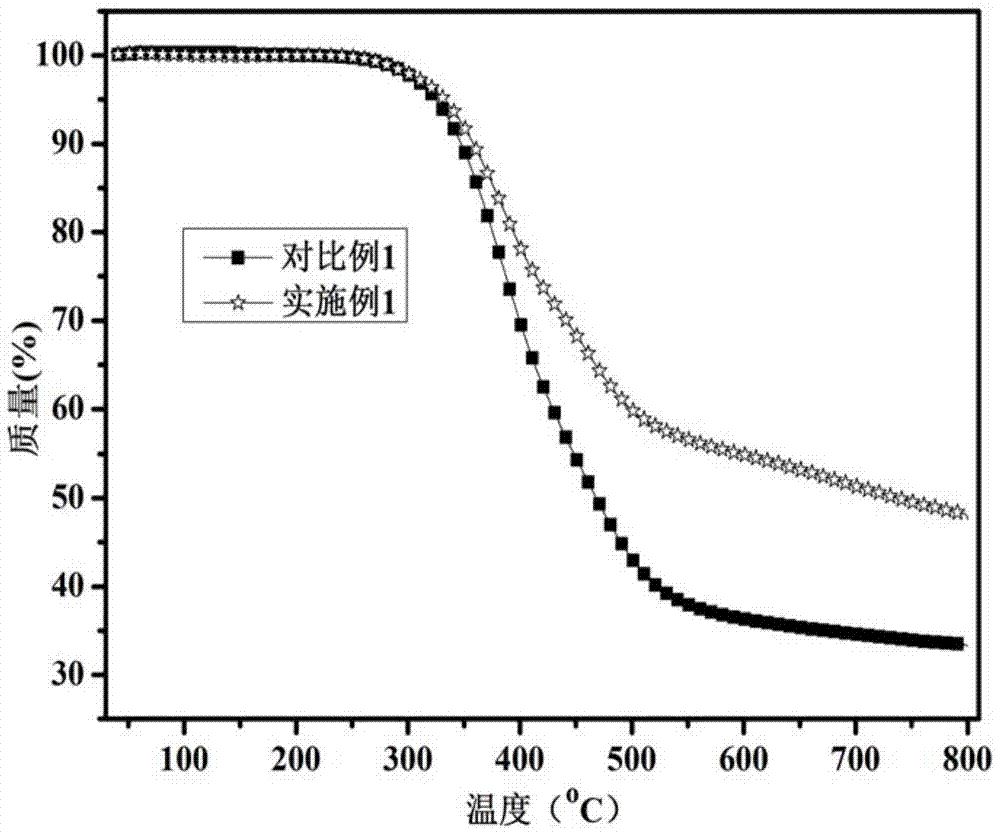

A nano-composite material and benzoxazine technology are applied in the field of novel functional polymer materials and their preparation, which can solve the problems of lowering the ring-opening curing temperature of benzoxazine monomers, lowering the thermal stability of polymer materials, and the like. Good thermal stability, high strength and good Young's modulus, the effect of reducing the temperature of ring-opening polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Disperse 5 parts of α-zirconium phosphate powder with a ratio of sheet layer diameter to thickness of 20 in 200 parts of acetone under 40 Hz ultrasonic conditions to obtain α-zirconium phosphate powder-acetone suspension. Weigh 16 parts of structure I monofunctional polyetheramine with a molecular weight of 1000 and disperse them in 50 parts of acetone to obtain a structure I monofunctional polyetheramine-acetone dispersion. The structure I monofunctional polyetheramine-acetone dispersion was added dropwise to the α-zirconium phosphate powder-acetone suspension within 25 minutes. After the dripping is completed, 40 Hz ultrasonic dispersion is performed for 1 hour, and the magnetic particles are stirred for 24 hours to obtain α-zirconium phosphate-structure I monofunctional polyetheramine-acetone stripping solution. Centrifuge the α-zirconium phosphate-structure I monofunctional polyetheramine-acetone stripping solution with a speed of 10,000 rpm. The α-Zirconium Phospha...

Embodiment 2

[0059] Disperse 15 parts of α-zirconium phosphate powder with a ratio of layer diameter to thickness of 5 in 500 parts of acetone under 100 Hz ultrasonic conditions to obtain α-zirconium phosphate powder-acetone suspension. Weigh 50 parts of structure III type bifunctional polyetheramine with a molecular weight of 600, and disperse them in 60 parts of acetone to obtain a structure III type bifunctional polyetheramine-acetone dispersion. The structure III bifunctional polyetheramine-acetone dispersion was added dropwise to the α-zirconium phosphate powder-acetone suspension within 60 minutes. After the dripping is completed, 100 Hz ultrasonic dispersion is performed for 1 hour, and the magnetic particles are stirred for 12 hours to obtain an α-zirconium phosphate-structure III bifunctional polyetheramine-acetone stripping solution. Centrifuge the α-zirconium phosphate-structure III type monofunctional polyetheramine-acetone stripping solution at a speed of 5000 rpm. The α-zirco...

Embodiment 3

[0062] Disperse 5 parts of α-zirconium phosphate powder with a ratio of sheet diameter to thickness of 20 in 250 parts of acetone under 40 Hz ultrasonic conditions to obtain α-zirconium phosphate powder-acetone suspension. Weigh 16 parts of structure I monofunctional polyetheramine with a molecular weight of 1000 and disperse them in 50 parts of acetone to obtain a structure I monofunctional polyetheramine-acetone dispersion. The structure I monofunctional polyetheramine-acetone dispersion was added dropwise to the α-zirconium phosphate powder-acetone suspension within 25 minutes. After the dripping is completed, 40 Hz ultrasonic dispersion is performed for 1 hour, and the magnetic particles are stirred for 18 hours to obtain α-zirconium phosphate-structure I monofunctional polyetheramine-acetone stripping solution. Centrifuge the α-zirconium phosphate-structure I monofunctional polyetheramine-acetone stripping solution with a speed of 10,000 rpm. The α-Zirconium Phosphate-Str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com