Bimetallic two-dimensional MOF series catalyst applied to lithium-sulfur battery

A bimetallic and catalyst technology, applied in the field of development and research of new energy materials, can solve problems such as unfavorable scale utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of a bimetallic two-dimensional MOF tandem catalyst and its application in lithium-sulfur batteries, the following steps are adopted:

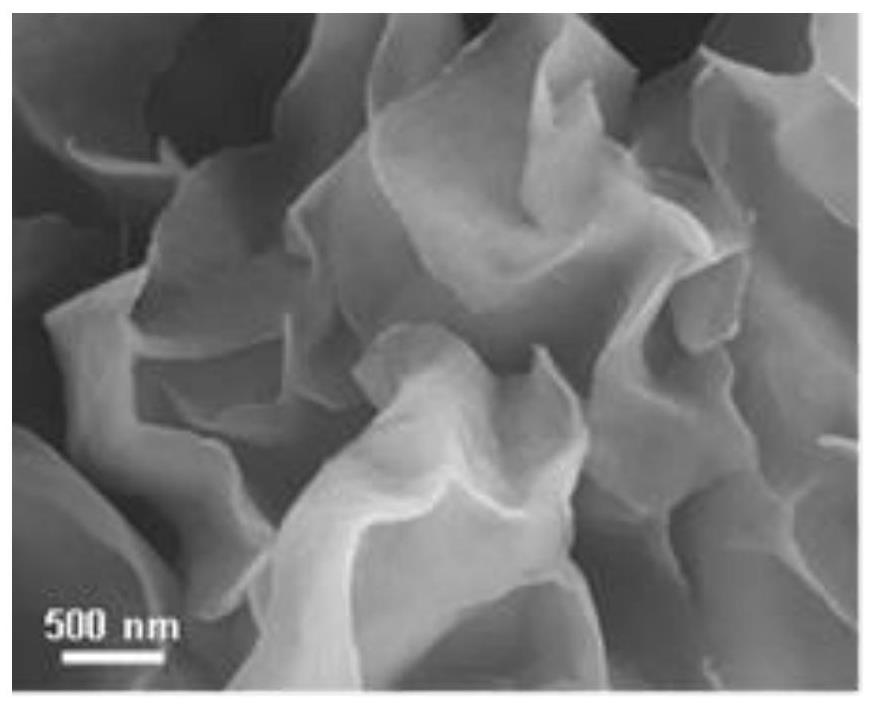

[0026] (1) 0.3mmol CoCl 2 ·6H 2 O, 0.3 mmol NiCl 2 ·6H 2 O, 0.78mmol terephthalic acid and 2.5mmol (ie 30mg) CMK-3 were ultrasonically dispersed in 4mL distilled water, 4mL ethanol and 62mL DMF, then added 6mmol triethylamine and stirred evenly, ultrasonicated at 200W for 10h, passed through DMF respectively and ethanol centrifugal washing, vacuum drying at 60 degrees to obtain a bimetallic two-dimensional MOF powder sample, its scanning electron microscope photo is as follows figure 1 As shown, the nanosheets prepared by the present invention are thin, uniform and transparent.

[0027] (2) Use bimetallic two-dimensional MOF series catalysts to support sulfur, the mass percentage of sulfur is 30%, dissolve sulfur in diethylamine and mix with MOF ethanol dispersion, add dilute nitric acid to neutralize and stir for 1 ...

Embodiment 2

[0029] The preparation of a bimetallic two-dimensional MOF tandem catalyst and its application in lithium-sulfur batteries, the following steps are adopted:

[0030] (1) 0.3mmol CoCl 2 ·6H 2 O, 0.3 mmol NiCl 2 ·6H 2O, 0.6mmol terephthalic acid, 0.6mmol KB were ultrasonically dispersed in 4mL distilled water, 4mL ethanol and 40mL DMF, then added 3mmol triethylamine and stirred evenly, ultrasonicated at 400W for 6h, washed by DMF and ethanol, respectively, vacuum 60 The bimetallic two-dimensional MOF powder samples were obtained by high-degree drying.

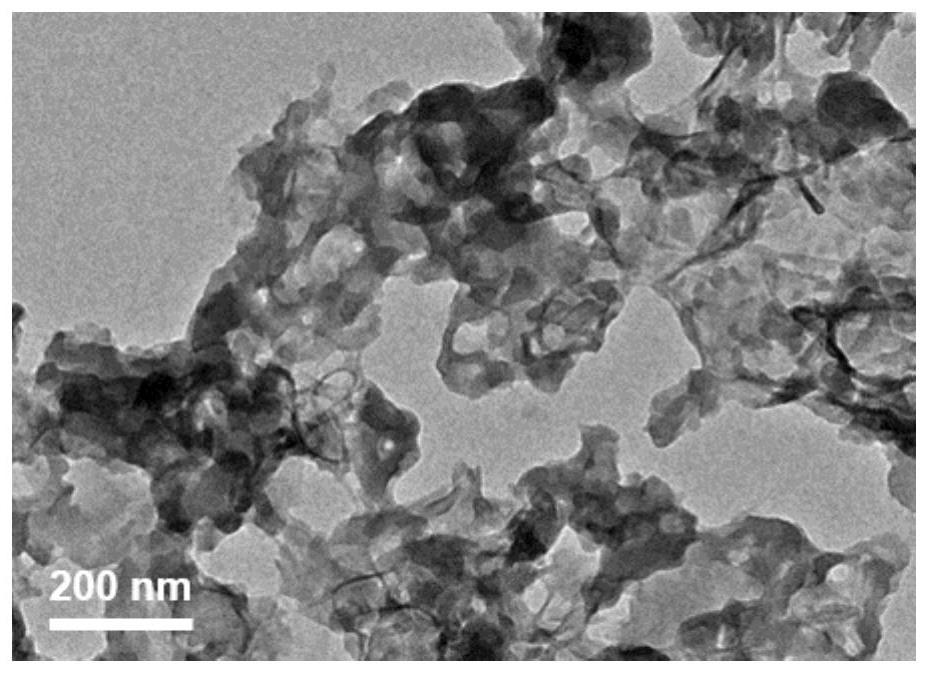

[0031] (2) Use bimetallic two-dimensional MOF series catalysts to support sulfur, the mass percentage of sulfur is 90%, dissolve sulfur in diethylamine and mix with MOF ethanol dispersion, add dilute nitric acid for neutralization, and stir for 3 hours. Its transmission electron microscope pictures are as figure 2 As shown, sulfur is uniformly distributed on the surface of the bimetallic MOF. Then the sulfur-loaded bimetal...

Embodiment 3

[0033] (1) 0.3mmol Co(NO 3 ) 2 ·6H 2 O, 0.3mmol Ni(NO 3 ) 2 ·6H 2 O, 0.9mmol terephthalic acid and 0.9mmol Super P were ultrasonically dispersed in 4mL distilled water, 4mL ethanol and 80mL DMF, then added 3mmol triethylamine and stirred evenly, and the mixed solution was transferred to a microwave tube, and placed in a microwave reactor React at 40°C for 0.5h, wash with DMF and ethanol, and dry in vacuum at 60°C to obtain a bimetallic two-dimensional MOF powder sample.

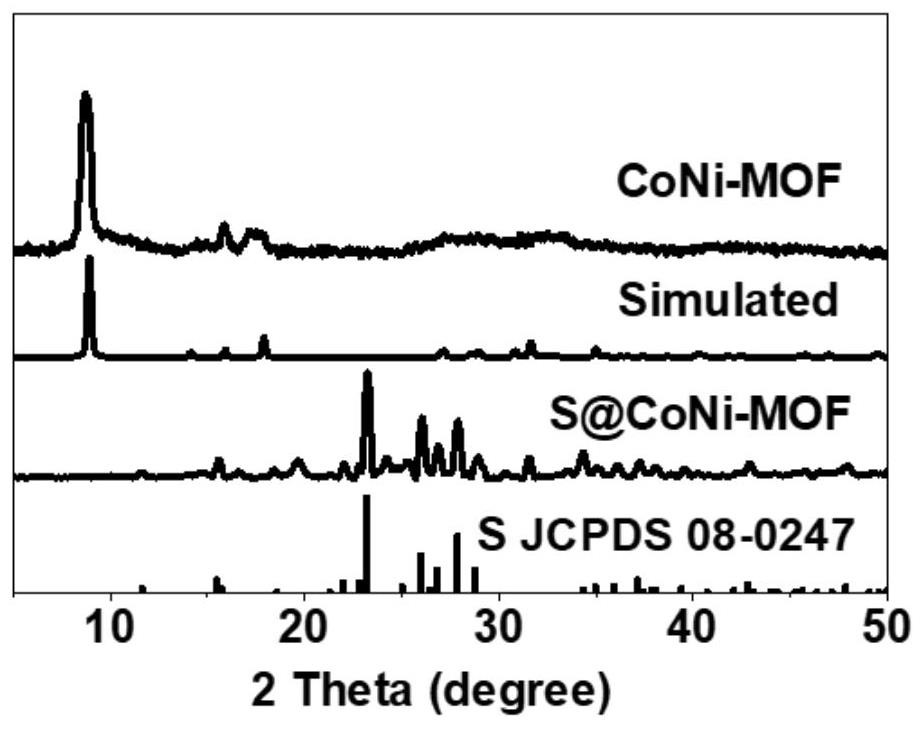

[0034] (2) Use bimetallic two-dimensional MOF series catalysts to support sulfur, the mass percentage of sulfur is 80%, dissolve sulfur in diethylamine and mix with MOF ethanol dispersion, add dilute nitric acid for neutralization, and stir for 0.5h , the X-ray diffraction patterns of the bimetallic two-dimensional MOF before and after sulfur loading are as follows image 3 As shown, it can be known that the bimetallic MOF is crystalline, and the XRD diffraction peaks of the MOF itself are covered by hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com