High-entropy alloy/carbon nanotube modified lithium carbon fluoride battery positive plate, preparation method thereof and lithium carbon fluoride battery

A lithium fluoride battery and carbon nanotube modification technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems such as hindering application, reduced electronic conductivity, poor rate performance, etc., and achieve high voltage The effect of platform and platform stability, improving rate capability, and improving electrochemical reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] This embodiment provides a method for preparing a positive electrode sheet of a high-entropy alloy / carbon nanotube modified lithium carbon fluoride battery, which includes the following steps:

[0039] Step 1, preparing high-entropy alloy / carbon nanotube composite material, the specific method is:

[0040] Step 1.1, according to iron, cobalt, copper, zinc, indium, nickel, carbon atom molar ratio is (0.1-1):(0.1-1):(0.1-1):(0.1-1):(0.1-1) :(5-20):(20-50) Weigh the iron source, cobalt source, copper source, zinc source, indium source, nickel source and carbon source respectively and mix them into the mortar, grind them to mix evenly, and get the mixture A;

[0041] Step 1.2, put the mixture A into a high-temperature tube furnace, raise the temperature from room temperature to 150-180°C at a rate of 10-30°C / min under an inert atmosphere, and then keep it warm for 0.5-2h;

[0042] Step 1.3, close the high-temperature tube furnace, take it out after the temperature in the ...

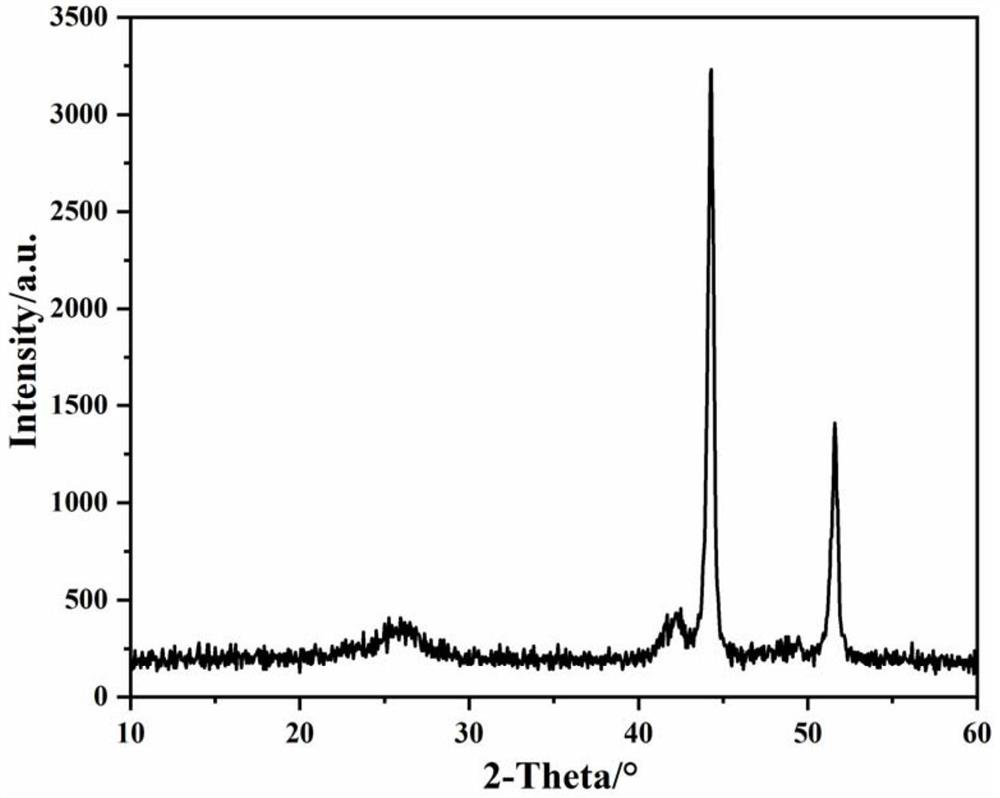

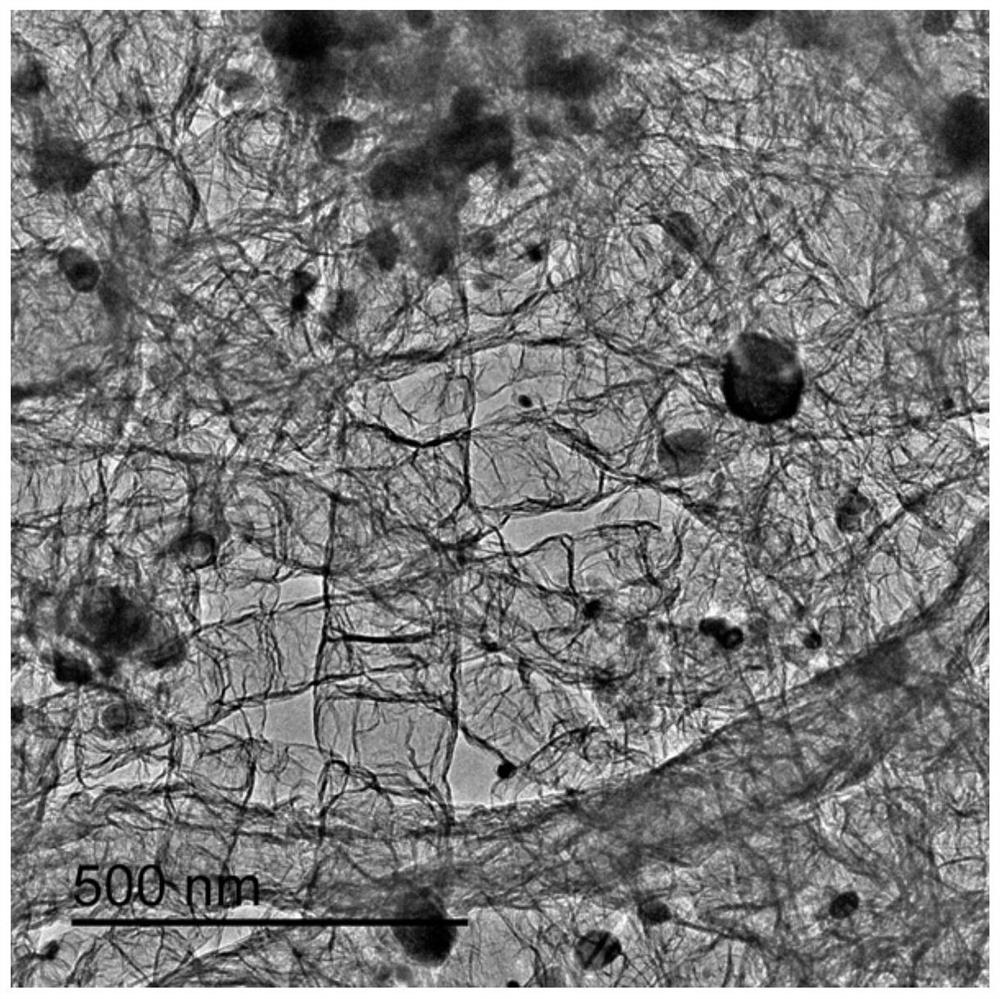

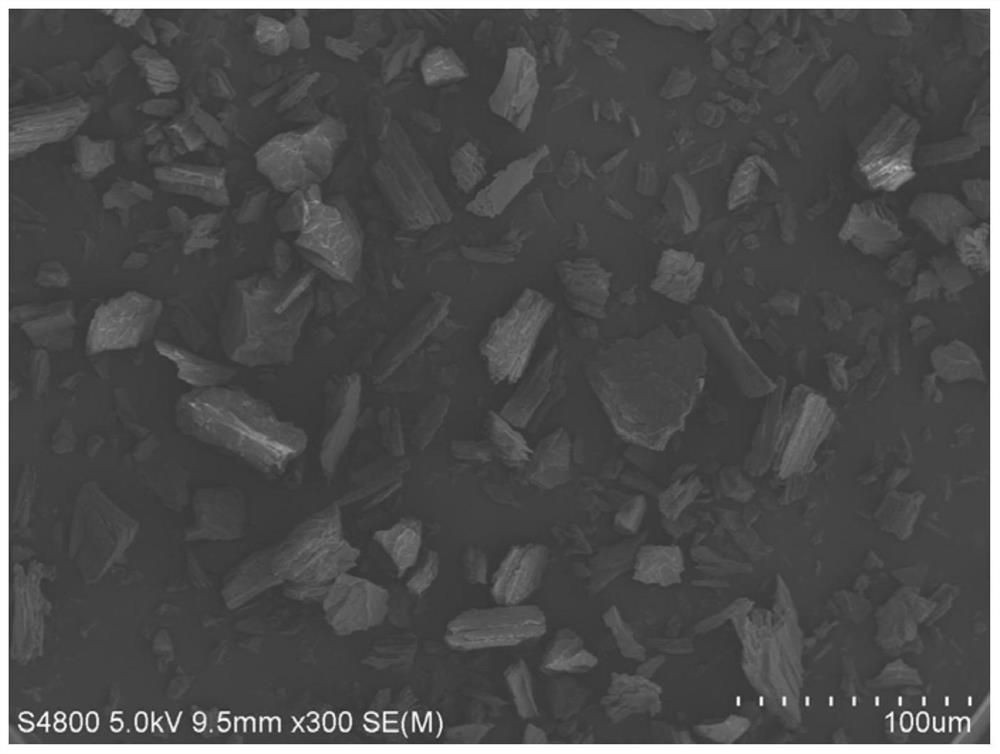

Embodiment 1

[0052] A method for preparing a high-entropy alloy / carbon nanotube modified lithium carbon fluoride battery cathode sheet, comprising the following steps:

[0053]Step 1, preparing high-entropy alloy / carbon nanotube composite material, the specific method is:

[0054] Step 1.1, according to iron, cobalt, copper, zinc, indium, nickel, carbon atom molar ratio is 0.1: 0.128: 0.155: 0.17: 0.124: 5.78: 24.78 respectively weigh ammonium oxalate iron salt, cobalt nitrate, copper nitrate, zinc acetate , indium nitrate, nickel nitrate hexahydrate, and melamine were mixed and added to an agate mortar, ground for 20 minutes, and mixed evenly to obtain mixture A;

[0055] Step 1.2, put the mixture A into a high-temperature tube furnace, heat it from room temperature to 180°C at a rate of 30°C / min under a nitrogen atmosphere of 80sccm, and then keep it warm for 0.5h;

[0056] Step 1.3, close the high-temperature tube furnace, take it out after the temperature in the furnace drops to room ...

Embodiment 2

[0064] A method for preparing a high-entropy alloy / carbon nanotube modified lithium carbon fluoride battery cathode sheet, comprising the following steps:

[0065] Step 1, preparing high-entropy alloy / carbon nanotube composite material, the specific method is:

[0066] Step 1.1, weigh ferrous ammonium sulfate, cobalt carbonate, cuprous chloride, Zinc sulfate, indium sulfate, nickel sulfate and urea were mixed and added to an agate mortar, ground for 15 minutes, and mixed evenly to obtain mixture A;

[0067] Step 1.2, put the mixture A into a high-temperature tube furnace, heat it from room temperature to 150°C at a rate of 10°C / min under a nitrogen atmosphere of 120 sccm, and then keep it warm for 2 hours;

[0068] Step 1.3, close the high-temperature tube furnace, take it out after the temperature in the furnace drops to room temperature, and then seal it in a glass bottle filled with argon through the glove box, and put the glass bottle into a microwave synthesis instrument...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com