Method for preparing GaN-based electronic device

A technology for electronic devices and microwave devices is applied in the field of preparing GaN-based electronic devices and semiconductor devices. The effect of reducing RF loss and ensuring crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

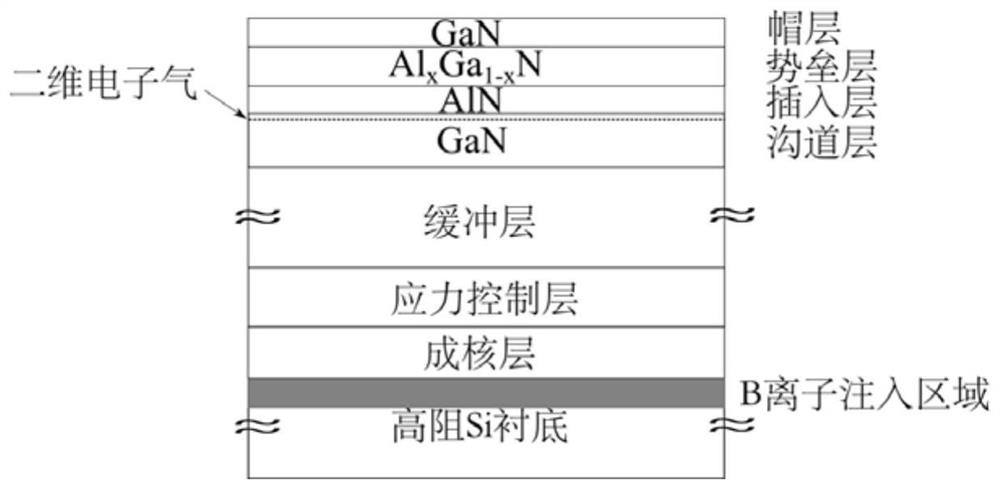

[0089] Embodiment 1: A preparation process of a silicon-based GaN radio frequency microwave device comprises the following steps:

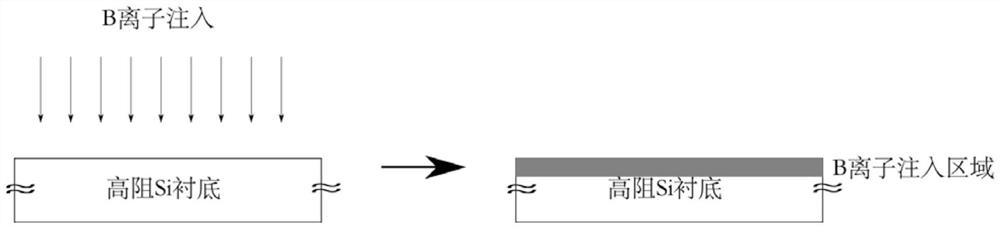

[0090] 1) High resistance Si substrate (resistivity>10 4 Ω cm) surface doping. Using boron ion implantation, the implantation energy is 1keV, and the implantation dose is 1×10 6 / cm 2 .

[0091] 2) B ion activation. The rapid annealing process is adopted, the annealing temperature is 1000°C, the annealing time is 30s, and the annealing atmosphere is nitrogen.

[0092] 3) AlN nucleation layer growth. Using MOCVD equipment, heat treatment at a temperature of 1100°C and hydrogen atmosphere for 5 minutes to remove the surface oxide layer; then lower the temperature to 1080°C, feed Al source to pre-spread Al; finally control the pressure of the reaction chamber to 10mbar, the flow rate of TMAl to 20sccm, and the flow rate of ammonia gas to 1slm , to grow an AlN nucleation layer with a thickness of 10nm.

[0093] 4) Gradual Al composition stress ...

Embodiment 2

[0101] Embodiment 2: A preparation process of a silicon-based GaN radio frequency microwave device comprises the following steps:

[0102] 1) High resistance Si substrate (resistivity>10 4 Ω cm) surface doping. Boron ion implantation is adopted, the implantation energy is 1MeV, and the implantation dose is 1×10 20 / cm 2 ,Such as figure 1 shown.

[0103] 2) B ion activation. The rapid annealing process is adopted, the annealing temperature is 700°C, the annealing time is 30min, and the annealing atmosphere is nitrogen.

[0104] 3) AlN nucleation layer growth. Using MOCVD equipment, heat treatment at a temperature of 1050°C and hydrogen atmosphere for 5 minutes to remove the surface oxide layer; then lower the temperature to 1000°C, feed Al source to pre-spread Al; finally control the pressure of the reaction chamber to 200mbar, the flow rate of TMAl to 200sccm, and the flow rate of ammonia gas to 20slm , to grow an AlN nucleation layer with a thickness of 1000nm.

[010...

Embodiment 3

[0112] Embodiment 3: A preparation process of a silicon-based GaN radio frequency microwave device comprises the following steps:

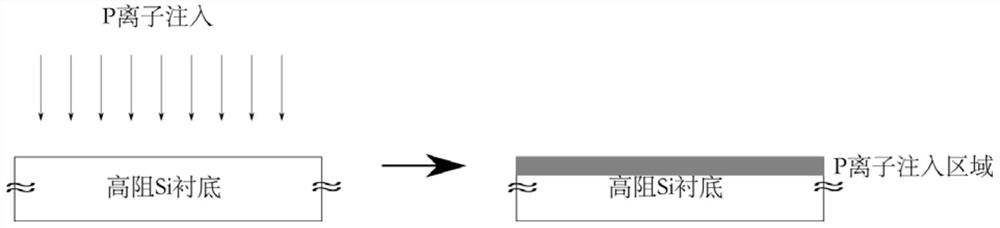

[0113] 1) High resistance Si substrate (resistivity>10 4 Ω cm) surface doping. Phosphorus (P) ion implantation is adopted, the implantation energy is 0.5MeV, and the implantation dose is 5×10 10 / cm 2 .

[0114] 2) P ion activation. The rapid annealing process is adopted, the annealing temperature is 900°C, the annealing time is 1min, and the annealing atmosphere is nitrogen.

[0115] 3) AlN nucleation layer growth. Using MOCVD equipment, heat treatment at a temperature of 1100°C and hydrogen atmosphere for 5 minutes to remove the surface oxide layer; then lower the temperature to 1000°C, feed Al source to pre-spread Al; finally control the pressure of the reaction chamber to 100mbar, the flow rate of TMAl to 100sccm, and the flow rate of ammonia gas to 10slm , to grow an AlN nucleation layer with a thickness of 500nm.

[0116] 4) Gradual A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com