A kind of polymer composite material additive and its application

A technology of composite materials and additives, which is applied in the field of high-value utilization of biomass, can solve the problems of poor dispersion of inorganic nanoparticles, increase of materials, and difficulty in achieving nanoscale compounding, so as to improve high-temperature rheological properties and benefit costs. Reduce the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

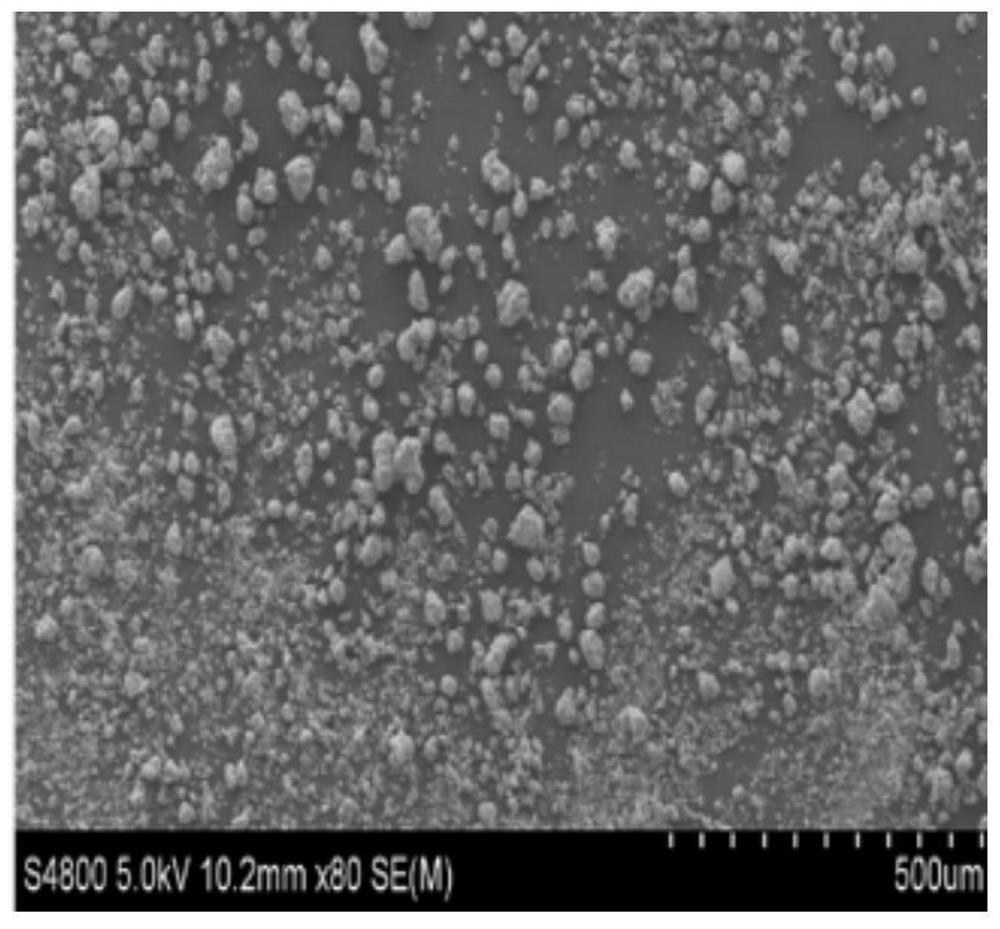

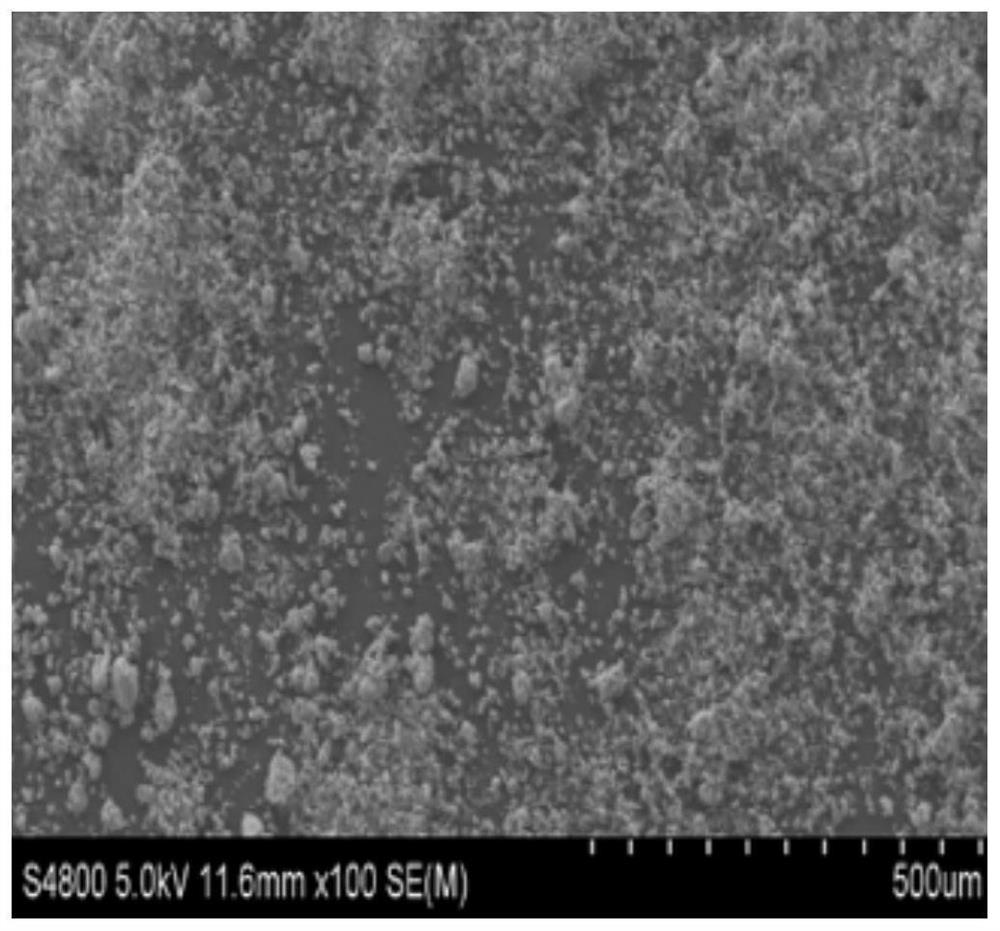

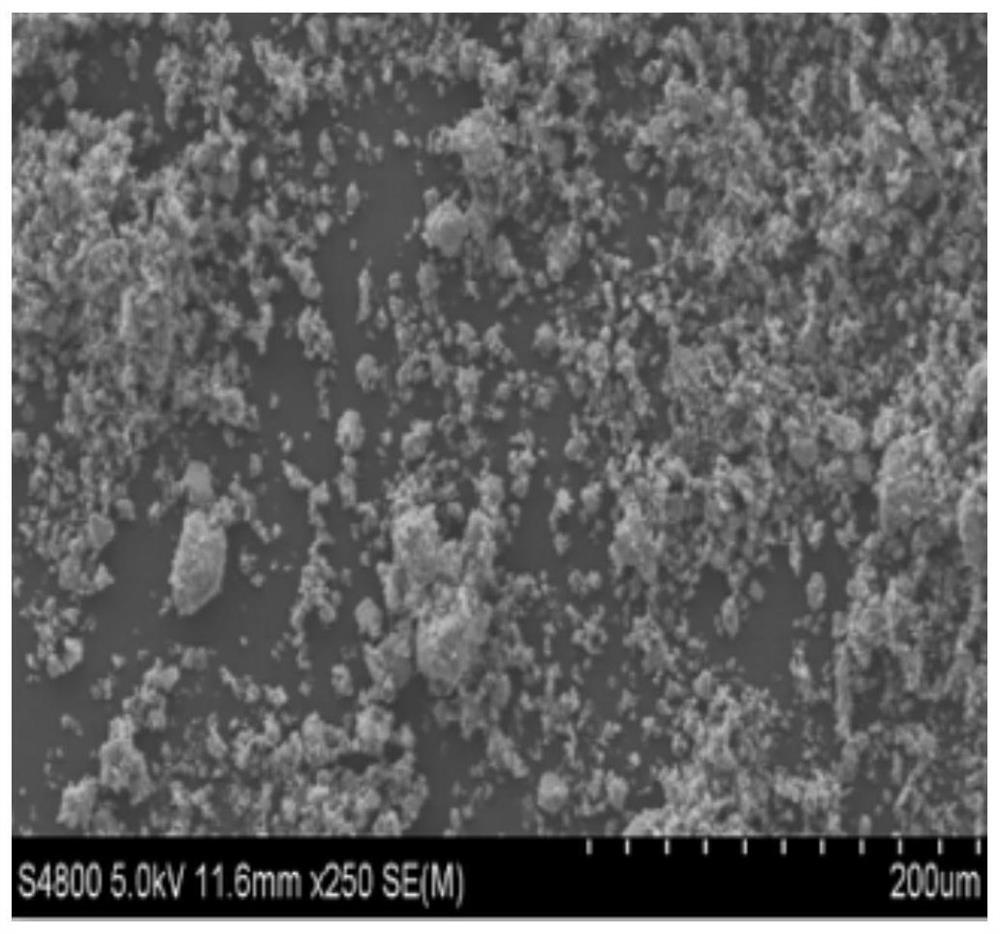

Image

Examples

Embodiment 1

[0064] Embodiment 1 (epoxidation+alkylation)

[0065] Solid acid catalyst with 1g of inorganic material 50nm SiO 2 with 1ml 0.75mol / L H 2 SO 4 The proportion of the solution was impregnated for 10 hours, dried at 100°C for 8 hours, and the obtained samples were activated by roasting at 400°C for 3 hours to obtain the corresponding SO 4 2- / SiO 2 solid acid catalyst;

[0066] Take 10g of rice husk powder and add it into a high-temperature and high-pressure reactor at 600°C and 0.1MPa pressure (gauge pressure) to prepare 4.3g of bio-oil. After the reaction, add 0.1g of SO to the liquefied bio-oil 4 2- / SiO 2 Solid acid catalyst, stirring, heating temperature to 40°C, and then slowly adding 20% hydrogen peroxide dropwise, wherein hydrogen peroxide accounts for 20wt% of the mass ratio of bio-oil, and after the addition, constant temperature reaction for 2h to obtain modified bio-oil a, Add fatty alcohol: octanol as the raw material for alkylation, which accounts for 10wt...

Embodiment 2

[0067] Embodiment 2 (epoxidation+esterification):

[0068] Solid acid catalyst with 1g of inorganic material 50nm SiO 2 with 1ml 0.75mol / L H 2 SO 4 The proportion of the solution was impregnated for 10 h, dried at 100 °C for 8 h, and then the obtained samples were activated by roasting at 400 °C for 3 h to obtain the corresponding SO 4 2- / SiO 2 solid acid catalyst;

[0069]Take 10g of rice husk powder and add it into a high-temperature and high-pressure reactor at 400°C and 0.2MPa (gauge pressure) to prepare 3.8g of bio-oil. After the reaction, add 0.1g of SO to the liquefied bio-oil 4 2- / SiO 2 Solid acid catalyst, stirring, heating temperature to 40°C, and then slowly adding 20% hydrogen peroxide dropwise, wherein hydrogen peroxide accounts for 20wt% of the mass ratio of bio-oil, after the addition, constant temperature reaction for 2h to obtain modified bio-oil a, Add polyol: pentaerythritol as the raw material of esterification, which accounts for 10wt% of the b...

Embodiment 3

[0070] Embodiment 3 (epoxidation+alkylation+esterification):

[0071] Solid acid catalyst with 1g of inorganic material 50nm SiO 2 with 1ml 0.75mol / L H 2 SO 4 The proportion of the solution was impregnated for 10 h, dried at 100 °C for 8 h, and the obtained samples were roasted at 400 °C for 3 h to obtain the corresponding SO 4 2- / SiO 2 solid acid catalyst;

[0072] Take 10g of rice husk powder and add it into a high-temperature and high-pressure reactor at 600°C and 0.1MPa (gauge pressure) to prepare 4.3g of bio-oil. After the reaction, add 0.1g of SO to the liquefied bio-oil 4 2- / SiO 2 Solid acid catalyst, stirring, heating temperature to 40°C, and then slowly adding 20% hydrogen peroxide dropwise, wherein hydrogen peroxide accounts for 20wt% of the mass ratio of bio-oil, after the addition, constant temperature reaction for 2h to obtain modified bio-oil a, Add fatty alcohol: octanol as raw material for alkylation, which accounts for 5wt% of bio-oil, set the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com