Anticarbon dioxide solid oxide fuel cell cathode material and preparation method thereof

A fuel cell cathode and solid oxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as corrosion and performance attenuation, and achieve the effects of overcoming severe attenuation, excellent stability, and good oxygen reduction catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides a method for preparing a solid oxide fuel cell cathode material described in any one of the above technical solutions, comprising:

[0030] A) dissolving Sr salt, Mn salt and Fe salt in dilute acid, adding citric acid and ethylenediaminetetraacetic acid, adjusting the pH value, stirring the reaction to obtain a reaction mixture;

[0031] B) continue heating the reaction mixture to obtain a precursor;

[0032] C) Calcining the precursor to obtain a solid oxide fuel cell cathode material.

[0033] The preparation method of the solid oxide fuel cell cathode material provided by the invention first dissolves Sr 2+ salt, soluble Mn 2+ Salt and Soluble Fe 3+ The salts were dissolved in dilute acid in sequence, and then citric acid and ethylenediaminetetraacetic acid were added.

[0034] The Sr salt of the present invention is preferably Sr(NO 3 ) 2 , the Mn salt is preferably (CH 3 COO) 2 Mn 4H 2 O; the Fe salt is preferably Fe(NO 3 ) ...

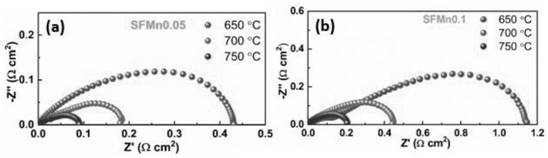

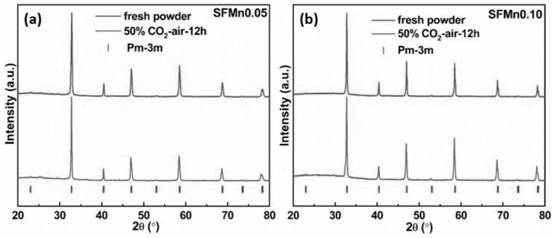

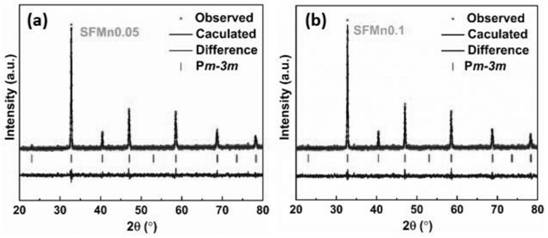

Embodiment 1

[0054] SrFe 0.9 mn 0.05 o 3-δ Powder preparation

[0055] Weigh Fe(NO 3 ) 3 9H 2 O (analytical pure) 19.19g, Sr (NO 3 ) 2 (analytical pure) 10.5815g and (CH 3 COO) 2 Mn 4H 2 O (analytical pure) 0.6127g is dissolved in dilute nitric acid solution, then adds citric acid (analytical pure) 31.521g and EDTA (analytical pure) 29.224g, drips ammoniacal liquor to adjust the pH value of the solution to be 7, and obtains a mixed solution; Use a magnetic stirrer to stir for two hours; use a heating furnace to heat the solution until it spontaneously ignites to obtain the battery cathode material—SrFe 0.95 mn 0.05 o 3-δ Precursor powder; calcining the precursor powder in a high-temperature sintering furnace at 1000°C for 2 hours to obtain the battery cathode material—SrFe 0.95 mn 0.05 o 3-δ Powder material.

Embodiment 2

[0057] SrFe 0.9 mn 0.1 o 3-δ Powder preparation

[0058] Weigh Fe(NO 3 ) 3 9H 2 O (analytical pure) 18.18g, Sr (NO 3 ) 2 (analytical pure) 10.5815g and (CH 3 COO) 2 Mn 4H 2 O (analytical pure) 1.2255g is dissolved in dilute nitric acid solution, then adds citric acid (analytical pure) 31.521g and EDTA (analytical pure) 29.224g, drips ammoniacal liquor and adjusts the pH value of the solution to be 7 to obtain a mixed solution; Use a magnetic stirrer to stir for two hours; use a heating furnace to heat the solution until it spontaneously ignites to obtain the battery cathode material—SrFe 0.9 mn 0.1 o 3-δ Precursor powder; calcining the precursor powder in a high-temperature sintering furnace at 1000°C for 2 hours to obtain the battery cathode material—SrFe 0.9 mn 0.1 o 3-δ Powder material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com