Preparation method of composite powder, dynamic friction sealing coating and preparation method

A technology of composite powder and sealing coating, which is applied in coatings, chemical instruments and methods, metal material coating technology, etc., can solve problems such as cracking, high stress, and reduce wear rate, so as to improve toughness and reduce the risk of cracking , good fluidity and the effect of spraying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

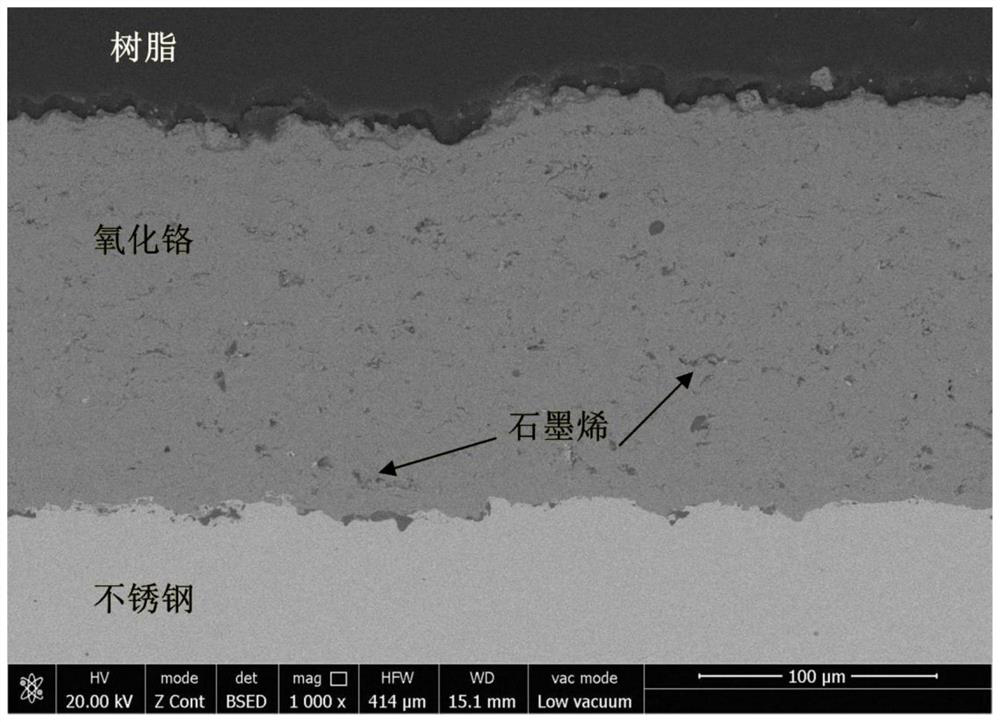

[0049] The preparation process of a kind of chromium oxide / graphene dynamic friction sealing coating of the present embodiment is as follows:

[0050] 1) Clean the surface of the substrate and perform sandblasting;

[0051] 2) Spray composite coating: use atmospheric plasma spraying method to spray chromium oxide / graphene composite powder on the surface of stainless steel substrate to prepare chromium oxide / graphene composite coating. The spraying parameters are: spraying distance 100mm, spraying current 650A, spraying Voltage 60V, H 2 The flow rate is 15L / min, the powder feeding rate is 20g / min, and the coating thickness is 0.3mm;

[0052] 3) Fine grinding: Use a fine grinder to grind and finish the surface of the composite coating, so that the surface roughness Ra reaches 0.05-0.2 μm, and the coating thickness after grinding is about 0.2 mm.

[0053] Described step 2) in, the preparation method of chromium oxide / graphene composite powder is as follows:

[0054] 21) Prepar...

Embodiment 2

[0060] The preparation process of a kind of chromium oxide / graphene dynamic friction sealing coating of the present embodiment is as follows:

[0061] 1) Clean the surface of the substrate and perform sandblasting;

[0062] 2) Spray composite coating: use atmospheric plasma spraying method to spray chromium oxide / graphene composite powder on the surface of stainless steel substrate to prepare chromium oxide / graphene composite coating. The spraying parameters are: spraying distance 95mm, spraying current 630A, spraying Voltage 55V, H 2 The flow rate is 10L / min, the powder feeding rate is 15g / min, and the coating thickness is 0.45mm.

[0063] 3) Fine grinding: Use a fine grinder to grind and finish the surface of the composite coating, so that the surface roughness Ra reaches 0.05-0.2 μm, and the coating thickness after grinding is about 0.32 mm.

[0064] Described step 2) in, the preparation method of chromium oxide / graphene composite powder is as follows:

[0065] 21) Prepa...

Embodiment 3

[0071] The preparation process of a kind of chromium oxide / graphene dynamic friction sealing coating of the present embodiment is as follows:

[0072] 1) Clean the surface of the substrate and perform sandblasting;

[0073]2) Spray composite coating: use atmospheric plasma spraying method to spray chromium oxide / graphene composite powder on the surface of stainless steel substrate to prepare chromium oxide / graphene composite coating. The spraying parameters are: spraying distance 95mm, spraying current 630A, spraying Voltage 55V, H 2 The flow rate is 10L / min, the powder feeding rate is 15g / min, and the coating thickness is 0.6mm.

[0074] 3) Fine grinding: Use a fine grinder to grind and finish the surface of the composite coating, so that the surface roughness Ra reaches 0.05-0.2 μm, and the coating thickness after grinding is about 0.45 mm.

[0075] Described step 2) in, the preparation method of chromium oxide / graphene composite powder is as follows:

[0076] 21) Prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com