Device and method for continuously preparing aluminum-nickel-cobalt nanoparticles

A nanoparticle and preparation device technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, electrical components, etc., and can solve problems such as difficulties in metal nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

[0013] The preparation method of nanoparticle comprises the following steps:

[0014] 1) Alnico master alloy preparation: according to the formula (by mass percent): Al (aluminum) 8, Co (cobalt) 38, Ni (nickel) 14, Cu (copper) 4, Ti (titanium) 8 and Fe (Iron) 28 Weigh AlNiCo raw material powder, 200g in total. After fully grinding and mixing, the powder is formed into a block at 30MPa, and the block is put into a sintering furnace, and argon gas is introduced, and at 1250 oC Sintering under the condition of 6h, after sintering, cool down to room temperature with the furnace, then put the sintered block under the orientation magnetic field of 5000 Oe, keep it warm for 10min, and obtain the AlNiCo master alloy after cooling.

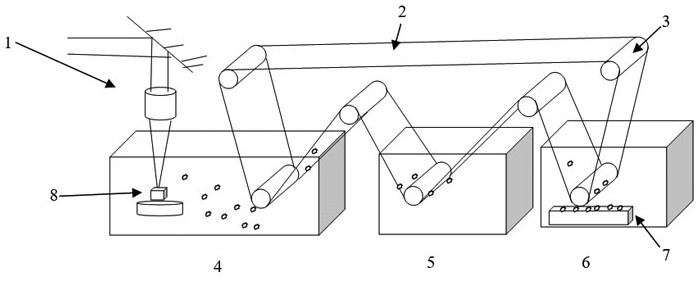

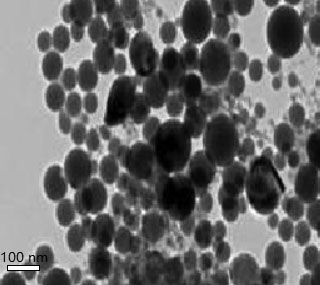

[0015] 2) Preparation of AlNiCo nanoparticles: Wire-cut the AlNiCo master alloy to obtain a 2cmⅹ2cmⅹ2cm master alloy block. Use an ultrasonic cleaning agent to clean the AlNiCo alloy block for 15 minutes. After drying, use it as a target material and put i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com