Device and method for optimizing low-grade laterite-nickel ore through gas-based direct reduction magnetic separation

A lateritic nickel ore and low-grade technology, which is applied in the field of energy-saving comprehensive utilization of mineral resources and direct reduction, can solve the problems of frustration in industrial production and application of gas-based shaft furnace technology, low nickel recovery rate, low grade of nickel alloy, and low production efficiency, etc. Ease of promotion, stable product quality, and reduced investment in environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

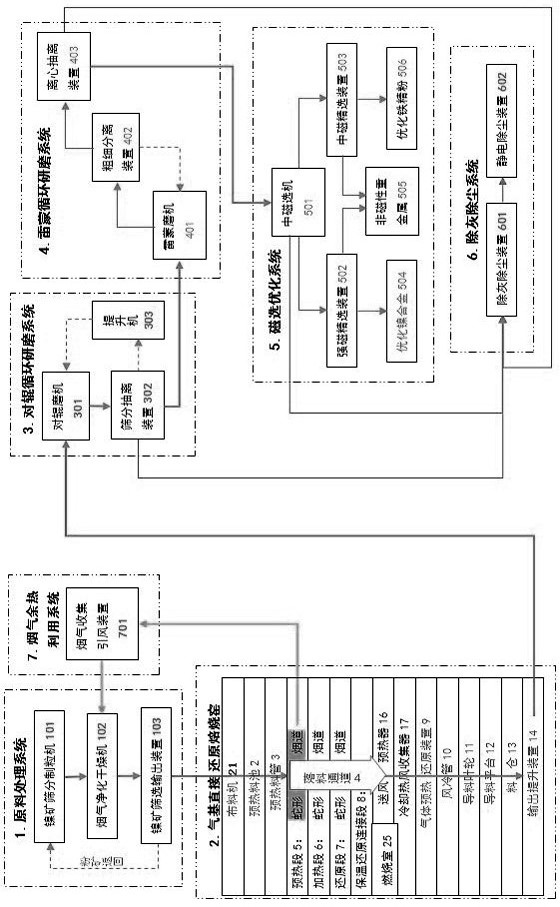

[0090] Ni0.85% and Fe49.17% of a low-grade lateritic nickel ore. Follow these steps:

[0091] ① Raw material treatment: sieve, granulate, dry and screen Ni0.85% and Fe49.17% laterite nickel ore raw materials to obtain granular nickel ore with a particle size of 3 to 40 mm, so that the water weight percentage is <10%;

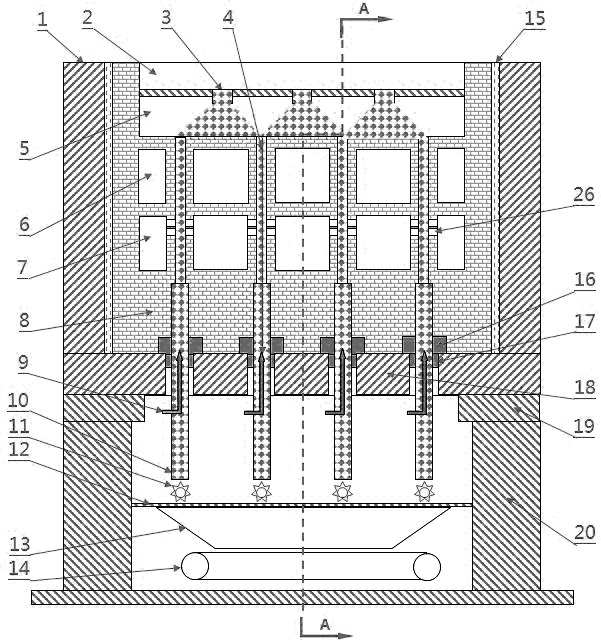

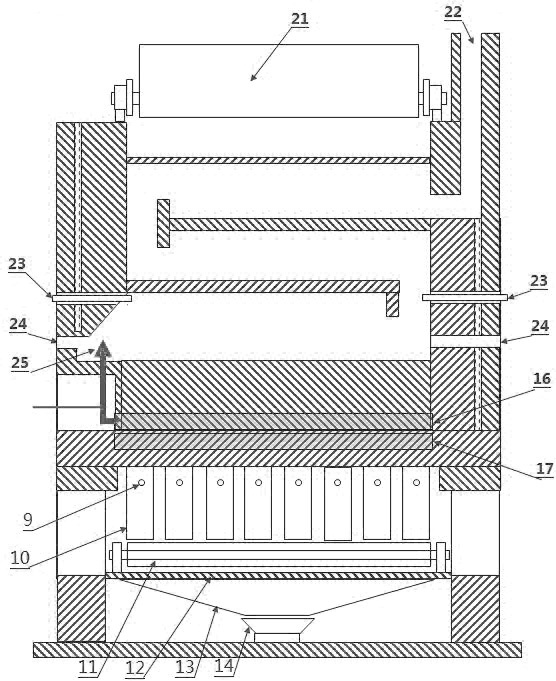

[0092] ② Gas-based direct reduction roasting: Roast 3-40mm granular nickel mineral materials in a gas-based direct reduction roasting test kiln. The gas-based reducing gas pressure is controlled at 600-1200Pa higher than the marked pressure, and the reduction temperature in the reduction section is controlled at 930°C Left and right, the speed of the material guide impeller is 5 revolutions per hour, and the material is discharged to obtain the roasted reduced material.

[0093] ③ Roller Grinding: The obtained reduced materials are successively ground to >200 mesh through the double-roller mill, screening and extraction device, hoist, and circular grinding, and...

Embodiment 2

[0098] Ni0.86% and Fe50.23% of a low-grade lateritic nickel ore. Follow these steps:

[0099] ① Raw material treatment: Screening, granulation, drying and screening of Ni0.86% and Fe50.23% laterite nickel ore raw materials to obtain granular nickel ore with a particle size of 3 to 40 mm, so that the water weight percentage is <10%;

[0100] ② Gas-based direct reduction roasting: Roast 3-40mm granular nickel mineral materials in a gas-based direct reduction roasting test kiln. The gas-based reducing gas pressure is controlled at 600-1200Pa higher than the marked pressure, and the reduction temperature in the reduction section is controlled at 930°C Left and right, the speed of the material guide impeller is 5 revolutions per hour, and the material is discharged to obtain the roasted reduced material.

[0101] ③ Roller Grinding: The obtained reduced materials are successively ground to >200 mesh through the double-roller mill, screening and extraction device, hoist, and circula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com