Molecularly imprinted photocatalytic material as well as preparation method and application thereof

A technology of photocatalytic materials and molecular imprinting, applied in the field of photocatalytic materials, can solve the problems of limited application and generation of free radicals, achieve fast electron transfer rate, improve separation degree, and be easy to recycle and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

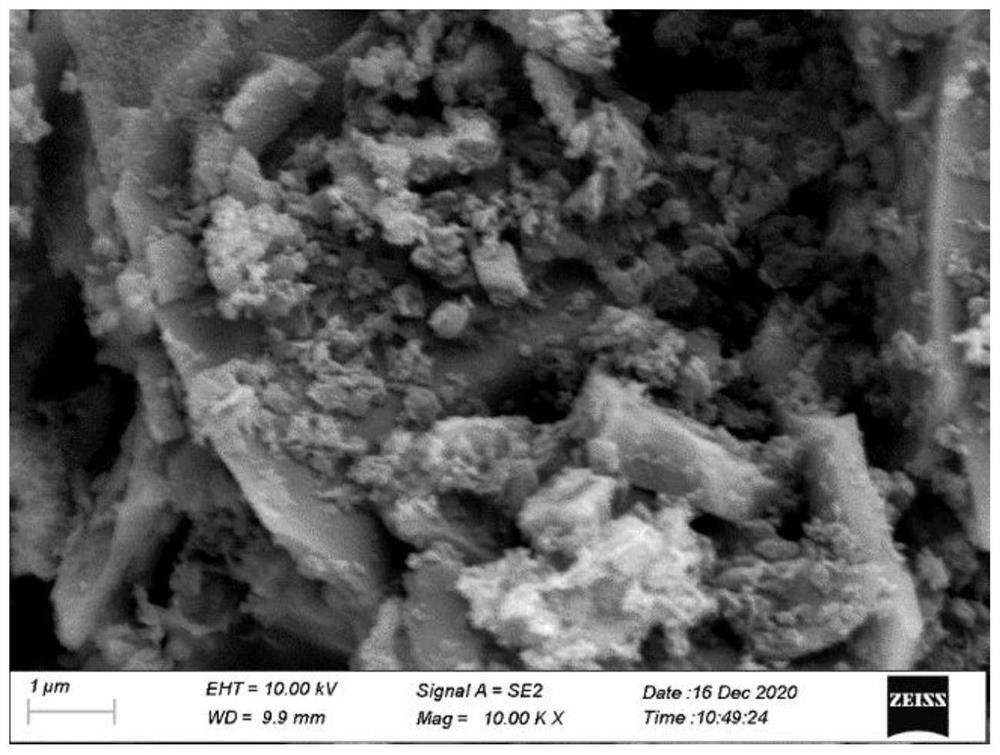

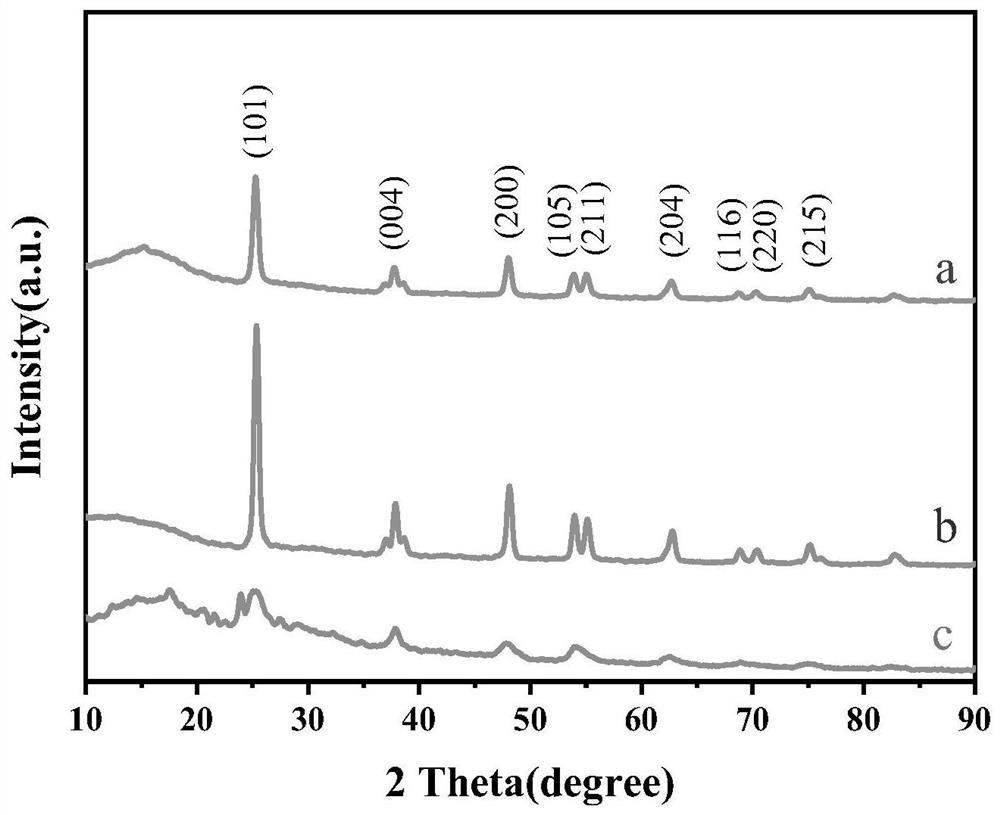

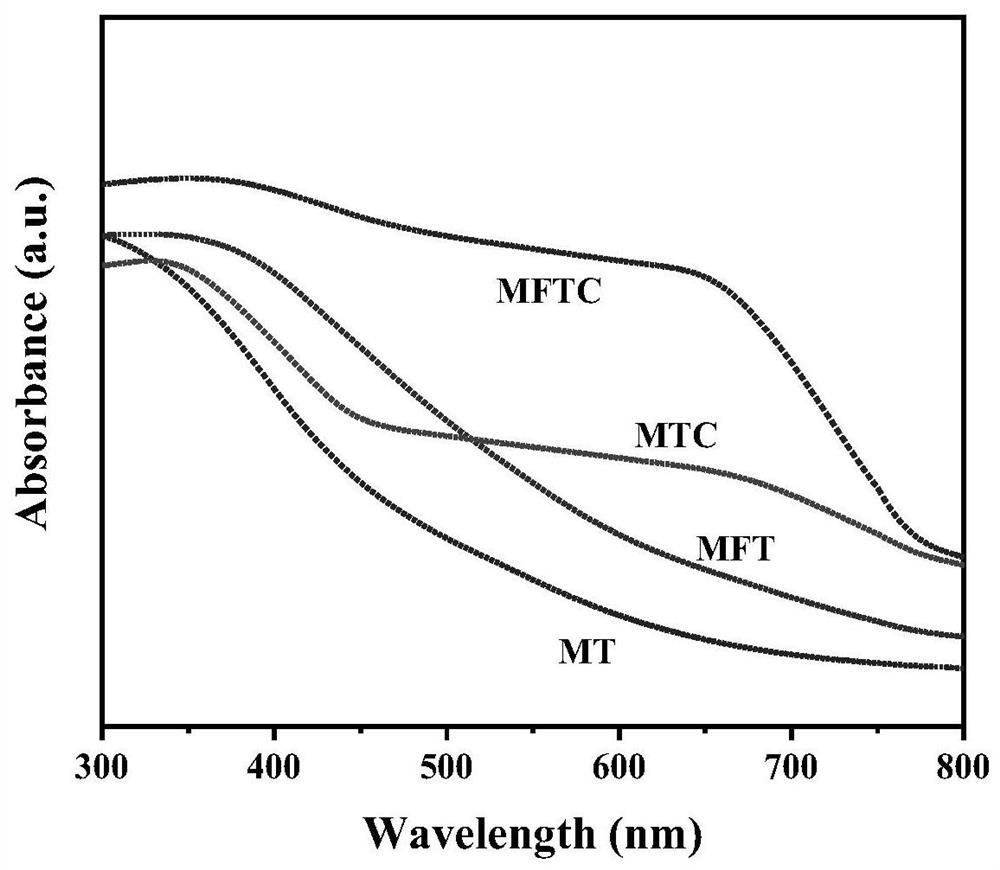

Image

Examples

Embodiment 1

[0042] Step 1, dissolve 10ml of n-butyl titanate, 1.438g of sulfamethoxazole (SMZ) and 10ml of glacial acetic acid in 60ml of absolute ethanol, stir evenly to obtain TiO 2 Sol;

[0043] Step 2, 0.1588gFeCl 3 ·6H 2 O was dissolved in 10ml of absolute ethanol to obtain solution A, and then solution A was gradually added to 50ml of distilled water, and vigorously stirred in a water bath at 90°C for 3 hours to form a uniform and transparent Fe 2 o 3 Sol;

[0044] Step 3, the TiO that step 1 makes 2 Sol and the Fe produced in step 2 2 o 3 The sol is mixed evenly to obtain TiO 2 / Fe 2 o 3 Composite sol, aged for 48h to form xerogel, the xerogel was ground into powder and calcined in a muffle furnace at 500°C for 4h to obtain TiO 2 / Fe 2 o 3 Complex;

[0045] Step 4: Put melamine in the crucible and cover the crucible, bake at 550°C for 3 hours, and cool to room temperature to obtain blocky yellow solid g-C 3 N 4 , the yellow solid g-C 3 N 4 Grind into powder, and 10...

Embodiment 2

[0057] The difference from Example 1 is that the imprinted molecule is BPA.

[0058] Results: When the catalyst material dosage was 100mg, the pollutant concentration was 10mg / L, and the volume was 100ml, the molecularly imprinted photocatalytic material prepared in this example had an adsorption rate of 12.8% for BPA and a 70min degradation rate for BPA of 99%.

Embodiment 3

[0060] The difference from Example 1 is that the imprinted molecule is SDZ, and in step 2 FeCl 3 ·6H 2 The amount of O added is 0.158g, and the temperature of calcination in step 3 is 600°C and the time is 2h.

[0061] Results: The molar ratio of titanium dioxide molecules to iron oxide in the molecularly imprinted photocatalytic material prepared in this example was 100:1.

[0062] When the amount of catalyst material is 100 mg, the pollutant concentration is 10 mg / L, and the volume is 100 ml, the adsorption rate of the molecularly imprinted photocatalytic material prepared in this example to SDZ is 13.4%, and the degradation rate to SDZ 120min is 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com