A kind of nickel niobium chromium master alloy and preparation method thereof

An intermediate alloy and chromium alloy technology, applied in the field of metal materials, can solve problems such as refractory element composition, melting point difference, element burning loss, etc., achieve low gas impurity content, improve uniformity and stability, and meet production requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

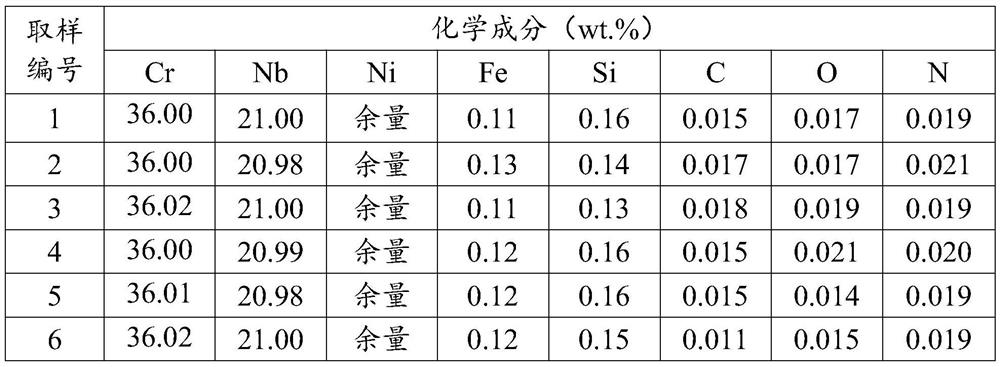

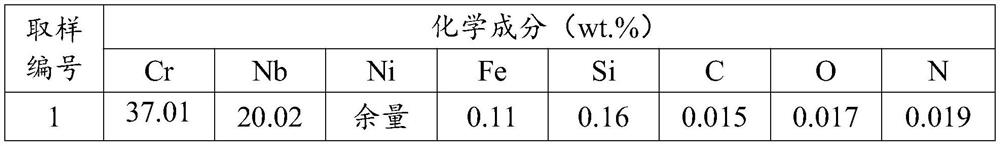

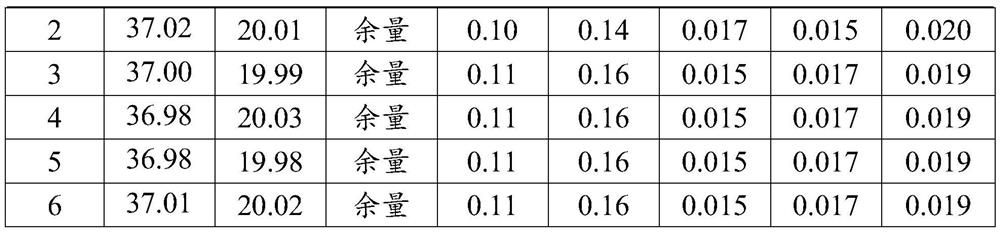

Embodiment 1

[0032] The preparation method of nickel niobium chromium master alloy specifically comprises the following steps:

[0033] (1) First dry niobium pentoxide, chromium trioxide and aluminum powder at 118°C for 12 hours, then weigh 90.33 kg of niobium pentoxide, 53.84 kg of chromium trioxide and 49.69 kg of aluminum powder and put them into V Fully mix in the type mixer, and then put the uniformly mixed charge into the sintered corundum crucible to ignite the reaction. The temperature of the thermite reaction is 1950°C, and the time is 45s. After cooling for 12 hours, remove the crucible and take out the alloy ingot. After removing the slag layer and oxide film on the surface of the alloy ingot, it is crushed and finished to 5-50mm, and after magnetic separation and manual selection, niobium-chromium alloy is obtained;

[0034] (2) First dry niobium-chromium alloy and electrolytic nickel at 120°C for 12 hours, then weigh 57.00 kg of niobium-chromium alloy and 43.00 kg of electroly...

Embodiment 2

[0037] The preparation method of nickel niobium chromium master alloy specifically comprises the following steps:

[0038] (1) First dry niobium pentoxide, chromium trioxide and aluminum powder at 119°C for 12 hours, then weigh 92.83 kg of niobium pentoxide, 51.29 kg of chromium trioxide and 49.63 kg of aluminum powder into V Fully mix in the type mixer, and then put the uniformly mixed charge into the sintered corundum crucible to ignite the reaction. The temperature of the thermite reaction is 1920°C, and the time is 45s. After cooling for 12 hours, remove the crucible and take out the alloy ingot. After removing the slag layer and oxide film on the surface of the alloy ingot, it is crushed and finished to 5-50mm, and after magnetic separation and manual selection, niobium-chromium alloy is obtained;

[0039] (2) First dry niobium-chromium alloy and electrolytic nickel at 120°C for 12 hours, then weigh 57.00 kg of niobium-chromium alloy and 43.00 kg of electrolytic nickel, m...

Embodiment 3

[0042] The preparation method of nickel niobium chromium master alloy specifically comprises the following steps:

[0043] (1) First dry niobium pentoxide, chromium trioxide and aluminum powder at 120°C for 12 hours, then weigh 96.59kg of niobium pentoxide, 47.44kg of chromium trioxide and 49.54kg of aluminum powder and put them into V Fully mix in the type mixer, and then put the uniformly mixed charge into the sintered corundum crucible to ignite the reaction. The temperature of the thermite reaction is 1900°C, and the time is 46s. After cooling for 12 hours, remove the crucible and take out the alloy ingot. After removing the slag layer and oxide film on the surface of the alloy ingot, it is crushed and finished to 5-50mm, and after magnetic separation and manual selection, niobium-chromium alloy is obtained;

[0044] (2) First dry niobium-chromium alloy and electrolytic nickel at 120°C for 12 hours, then weigh 57.00 kg of niobium-chromium alloy and 43.00 kg of electrolytic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com