Nickel boron carbon intermediate alloy and preparation method thereof

A master alloy, nickel-boron technology, applied in the field of nickel-boron-carbon master alloy and its preparation, can solve the problems of poor composition uniformity of alloy ingots and failure to meet the requirements of nickel-based superalloys, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

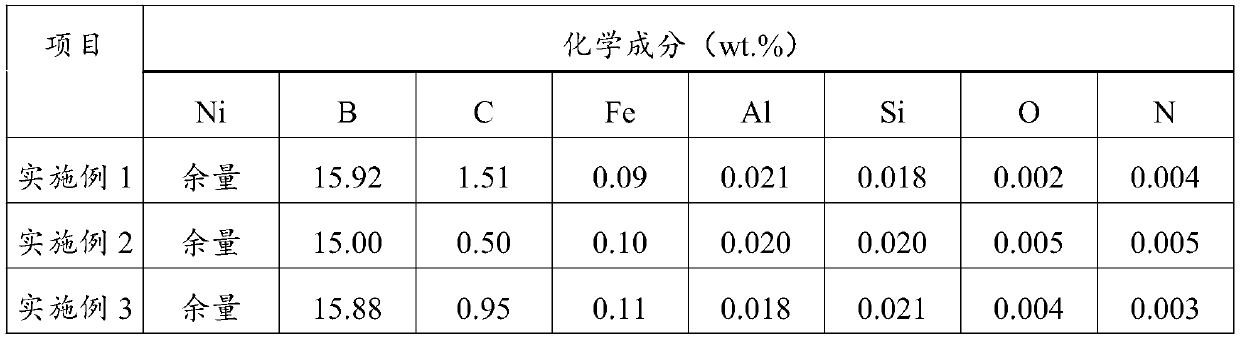

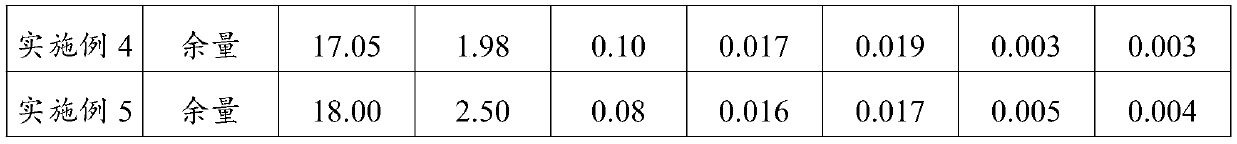

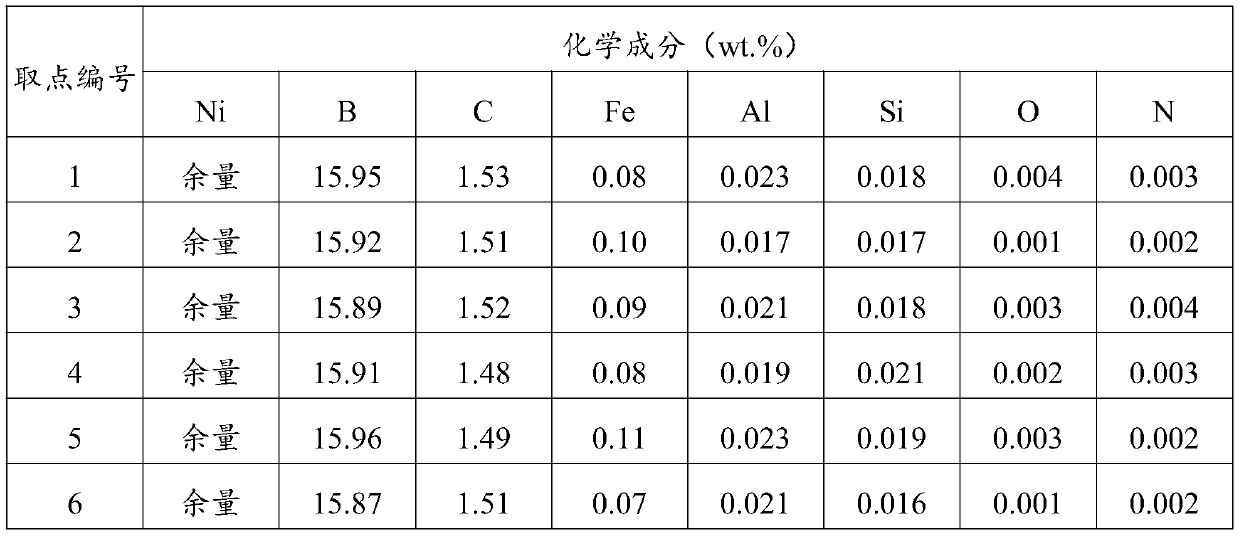

Examples

preparation example Construction

[0023] The present invention provides the preparation method of nickel-boron-carbon master alloy described in the above scheme, comprising the following steps:

[0024] (1) Aluminum, boric anhydride and nickel oxide are mixed for aluminothermic reaction, and a nickel-boron master alloy is obtained after cooling;

[0025] (2) Vacuum melting the nickel-boron master alloy with nickel and carbon, and cooling to obtain a nickel-boron-carbon master alloy.

[0026] The invention mixes aluminum, boric anhydride and nickel oxide for aluminothermic reaction, and obtains a nickel-boron master alloy after cooling. In the present invention, the mass ratio of aluminum, boron anhydride and nickel oxide is preferably (1.301-1.473):(1.018-1.273):(2.045-2.148), more preferably 1.473:1.273:2.045. In the present invention, the aluminum, boric anhydride and nickel oxide are preferably powders; the present invention has no special requirements on the source of the aluminum, boric anhydride and nic...

Embodiment 1

[0033] 1. Aluminum thermal smelting process

[0034] (1) Dry the aluminum powder, nickel oxide and boric anhydride at a temperature of 120°C for 12 hours.

[0035](2) Raw material ratio: aluminum powder 73.65kg, nickel oxide 102.25kg, boric anhydride 63.65kg. Load the raw materials into the V-type mixer and mix them evenly to ensure full contact between the raw materials.

[0036] (3) Put the evenly mixed charge into the built graphite crucible, ignite the reaction, cool for 6 hours, dismantle the furnace, take out the alloy ingot, and weigh.

[0037] (4) After removing the slag layer and oxide film on the surface of the alloy ingot, crushing and finishing to 5-50 mm, and after magnetic separation and manual selection, a nickel-boron intermediate alloy is obtained.

[0038] Second, the vacuum melting process

[0039] (1) The nickel, carbon powder, and nickel-boron intermediate alloy are subjected to drying treatment, the drying temperature is 120° C., and the drying time is...

Embodiment 2

[0046] 1. Aluminothermic smelting process

[0047] (1) The aluminum powder, nickel oxide, and boric anhydride are dried, and the drying temperature is 120° C., and the drying time is 12 hours.

[0048] (2) Raw material ratio: aluminum powder 73.65kg, nickel oxide 102.25kg, boric anhydride 63.65kg. Load the raw materials into the V-type mixer and mix them evenly to ensure full contact between the raw materials.

[0049] (3) Put the evenly mixed charge into the built graphite crucible, ignite the reaction, cool for 6 hours, dismantle the furnace, take out the alloy ingot, and weigh.

[0050] (4) After removing the slag layer and oxide film on the surface of the alloy ingot, crushing and finishing to 5-50 mm, and after magnetic separation and manual selection, a nickel-boron intermediate alloy is obtained.

[0051] Second, the vacuum melting process

[0052] (1) The nickel, carbon powder, and nickel-boron intermediate alloy are subjected to drying treatment, the drying tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com