Sintering method for low-stress hard alloy mold material

A mold material and cemented carbide technology, which is applied in the field of low-stress cemented carbide mold material sintering, can solve the problems of particle increase and decrease, and achieve the effect of low production cost, improved ability, and passivation of WC sharp corners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

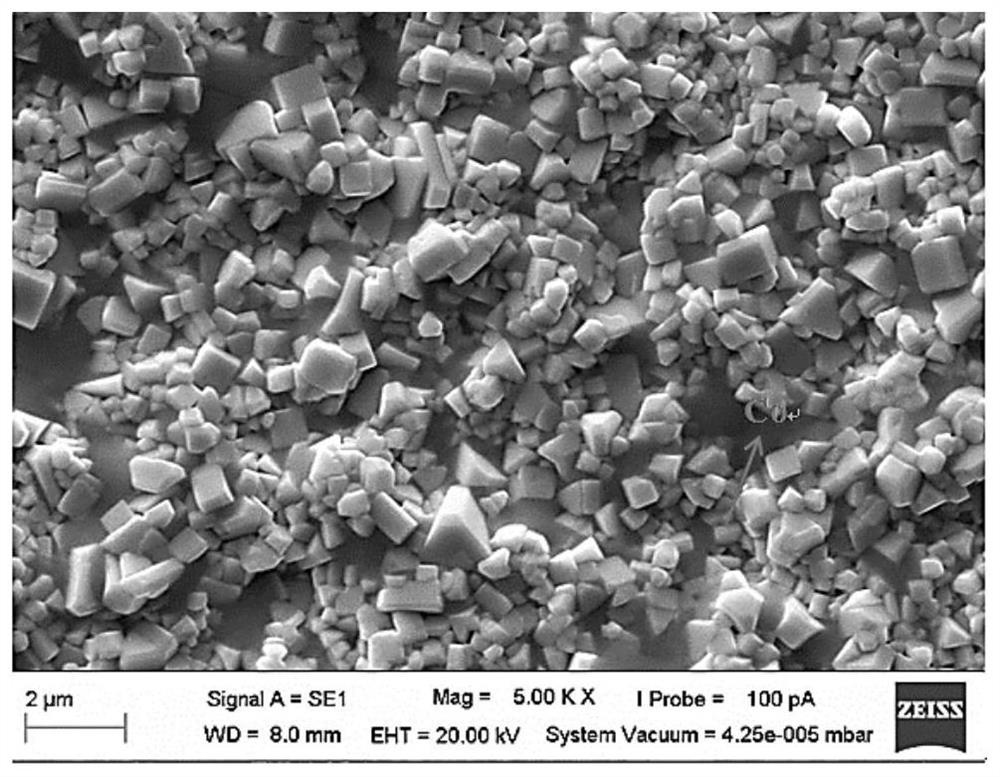

[0026] WC-13.0ωt% Co cemented carbide mold material, the original WC particle size is 1.0 μm, and the appearance size is 105mm × 105mm × 50mm. One piece is sintered by conventional technology, and the other is sintered by the method of the present invention. The specific steps of sintering by the method of the present invention are as follows: :

[0027] 1) Hydrogen positive pressure dewaxing: put the mold material plate compact containing the forming agent on the graphite plate coated with anti-stick high temperature coating and put it into the furnace with a volume of 0.1m 3 The dewaxing-sintering integrated low-pressure furnace is heated from room temperature to 350°C at a heating rate of 1.8°C / min, and kept at a temperature of 700 minutes and then continued to rise to 650°C at a heating rate of 1.8°C / min. The hydrogen flow rate is controlled at 35SLM throughout the process. The furnace pressure is controlled at 10mbar.

[0028] (2) Nitrogen dehydrogenation: After step (1)...

Embodiment 2

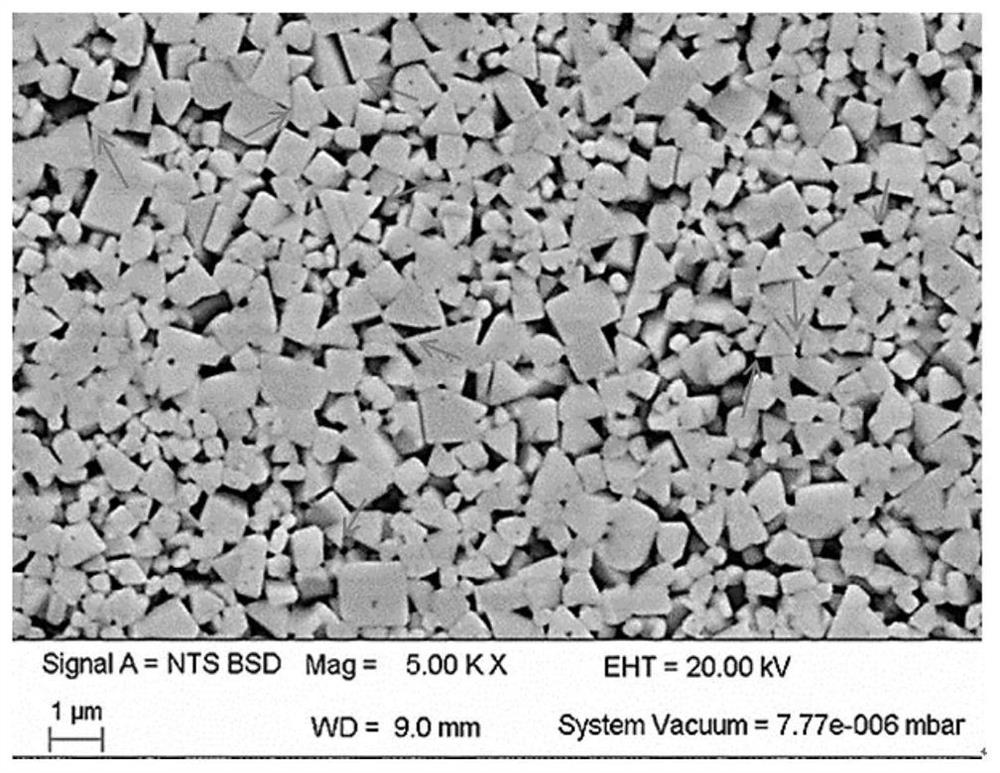

[0041] WC-16.0ωt% Co cemented carbide mold material, the original WC particle size is 3.0 μm, and the appearance size is 150mm × 150mm × 60mm. One piece is sintered by conventional technology, and the other is sintered by the method of the present invention. The specific steps of sintering by the method of the present invention are as follows: :

[0042] 1) Hydrogen positive pressure dewaxing: put the mold material plate compact containing the forming agent on the graphite plate coated with anti-stick high temperature coating and put it into the furnace with a volume of 0.1m 3 The dewaxing-sintering integrated low-pressure furnace is heated from room temperature to 350°C at a heating rate of 1.2°C / min, and kept at a temperature of 800 minutes, and then continues to rise to 650°C at a heating rate of 1.2°C / min. The hydrogen flow rate is controlled at 35SLM throughout the process. The furnace pressure is controlled at 10mbar.

[0043] (2) Nitrogen dehydrogenation: After step (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com