Furnace having even distribution of gas

A reduction furnace and gas technology, which is applied in the field of equipment for preparing molten iron, can solve the problems of uneven distribution of reducing gas and the inability to be supplied to the center of the reduction furnace, etc., and achieve facility capacity, uniform reduction rate, and improved operation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments of the present invention are described in detail with reference to the accompanying drawings.

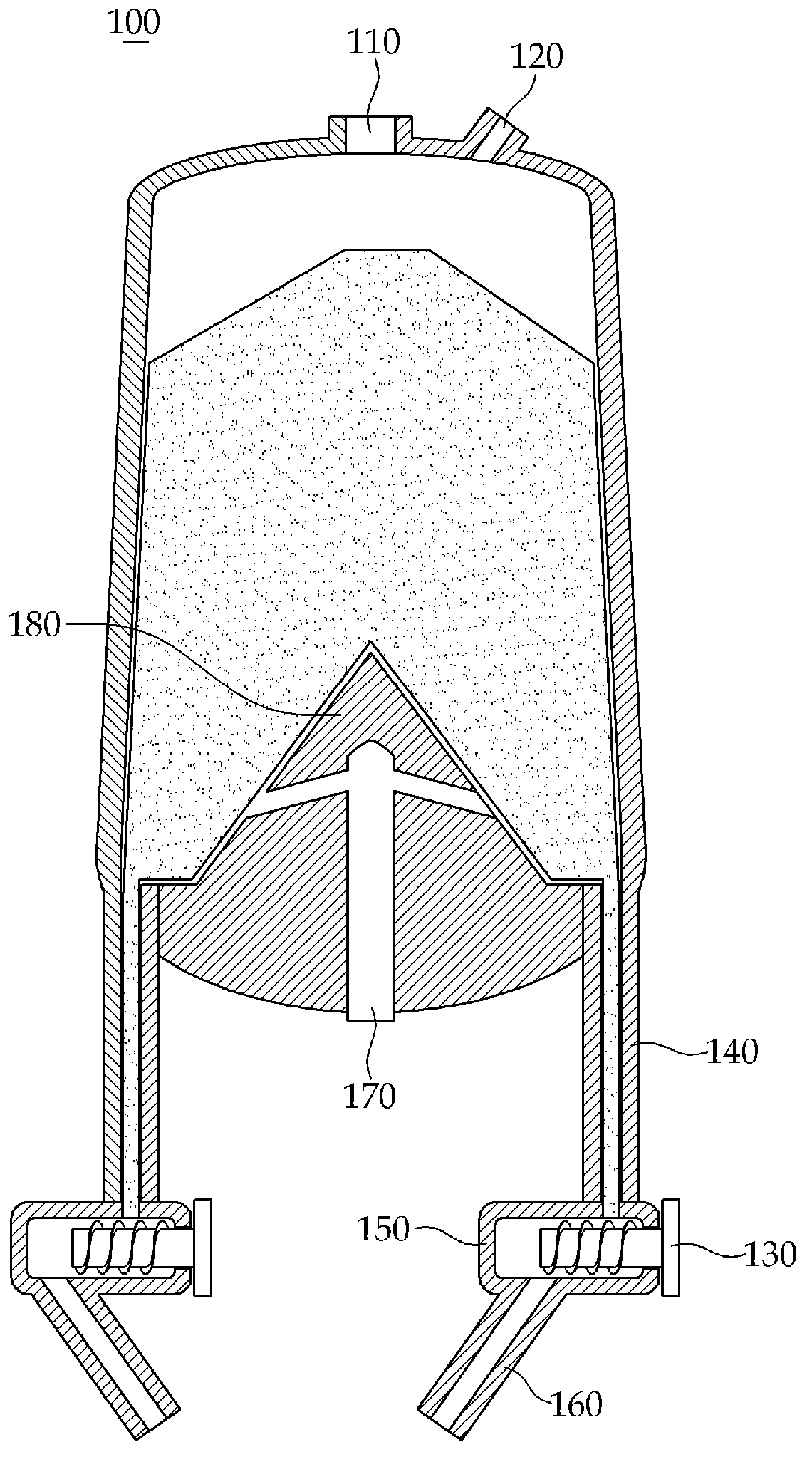

[0034] figure 2 is a longitudinal sectional view of a reduction furnace 100 according to an embodiment of the present invention. refer to figure 2 , the upper part of the reduction furnace 100 is provided with a burden input port 110 and a plurality of exhaust gas discharge ports 120 . A lower end inside the reduction furnace 100 is provided with a convex pile 180 (or a concave pile, these two terms are used interchangeably hereinafter). The protruding stakes 180 are provided to prevent the charge from bursting fire or the formation of a fixed layer caused by the load of the charge itself. The reducing gas blowing port 170 is provided at the bottom of the boss 180 , and a path is formed inside the boss 180 to allow the reducing gas blown through the reducing gas blowing port 170 to pass through. The reducing gas blowing port 170 is formed at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com