A kind of microwave roasting equipment

A microwave roasting and equipment technology, applied in the field of microwave roasting equipment, can solve problems such as poor exhaust, uneven material flow rate, local temperature exceeding the standard, etc., and achieve the effects of reducing impact force, promoting reduction rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The microwave roasting equipment of the present invention will be further described in detail with reference to the embodiments described in the accompanying drawings.

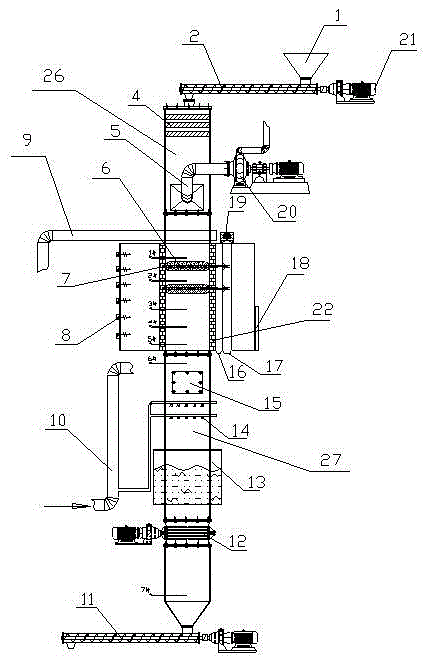

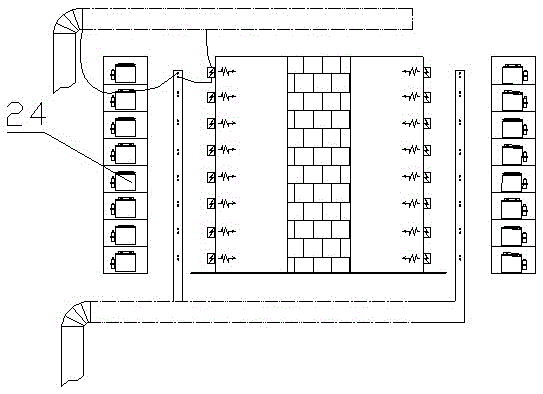

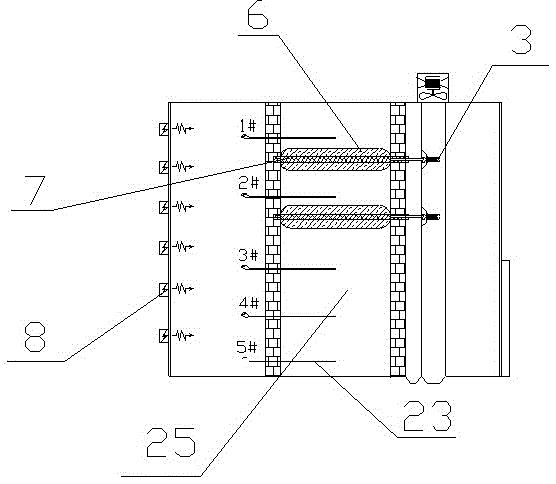

[0019] figure 1 It is a schematic structural diagram of the microwave roasting equipment of the present invention, mainly including a microwave roasting furnace, a material inlet and outlet device, a steam exhaust device, a microwave heating source and a cooling device; figure 2 yes figure 1 Schematic diagram of the enlarged structure of the roasting furnace in the microwave roasting equipment; image 3 yes figure 2 Side view of a microwave oven.

[0020] Depend on figure 2 and image 3 It can be seen that magnetrons 8 are distributed on the microwave roasting furnace, and the magnetrons 8 are connected to the microwave source oil tank 24. Thermocouples 23 are installed at intervals inside the roasting furnace, numbered 1# to 5#, and the thermocouples 23 are fixed On the refractory wall 22, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com