Preparation method of nano coating on surface of medical titanium alloy bone plate

A nano-coating and titanium alloy technology, applied in the field of medical titanium alloy, can solve the problems of nanotube coating wear resistance, poor bonding force, bacterial infection of titanium alloy bone plate, easy to cause adverse reactions, etc., to reduce harmful wear , increase the roughness, enhance the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

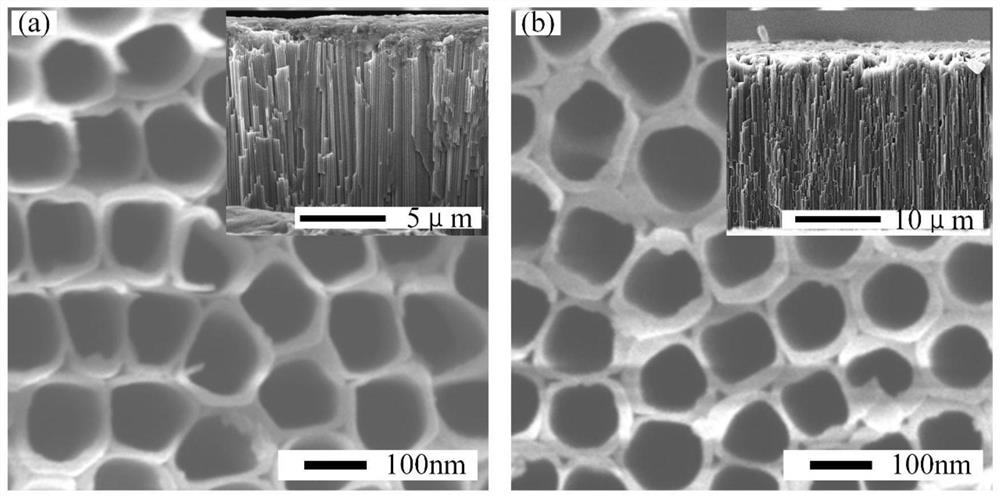

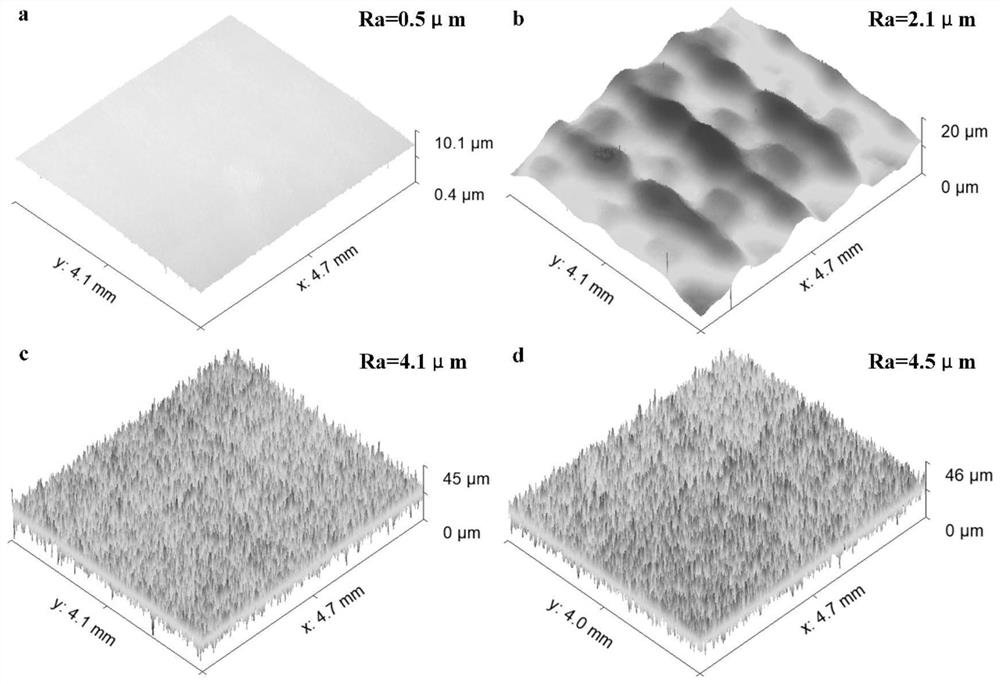

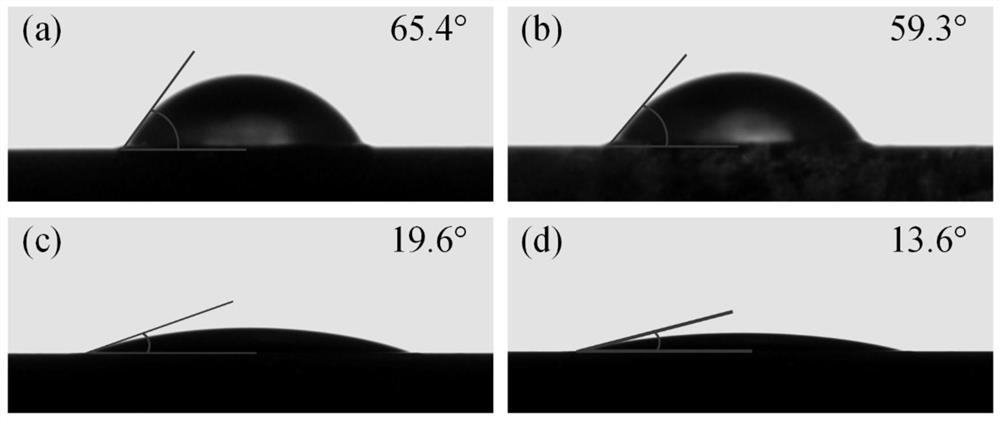

[0042] The preparation method of the nano-coating on the surface of the medical titanium alloy bone plate comprises the following steps:

[0043] Step 1), select the Ti6Al4V alloy plate for pretreatment, and make the base plate of medical titanium alloy bone plate to be processed;

[0044] In this embodiment, the thickness of the Ti6Al4V alloy plate is 3.5 mm.

[0045]The pretreatment includes: cutting the bone plate material Ti6Al4V into the bone plate processing size with a wire electric discharge machine; then using 600~2500# metallographic sandpaper to polish the surface of the sample without obvious scratches, and then using a polishing cloth for mechanical polishing After 5-10 minutes, each sample was polished into a mirror surface; it was ultrasonically cleaned with absolute ethanol and dried in a drying oven for later use.

[0046] Step 2), laser shock strengthening: use a laser with a pulse width of 20ns, a wavelength of 1064nm, and a working frequency of 5Hz; the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com