Preparation method of self-reinforced silicon carbide ceramic material

A technology of silicon carbide ceramics and carbonization temperature, which is applied in the field of preparation of self-reinforced silicon carbide ceramic materials, can solve the problems of softening, material waste, SiC material use strength and hardness deterioration, etc., to improve bending strength and wide application fields , the effect of inhibiting abnormal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

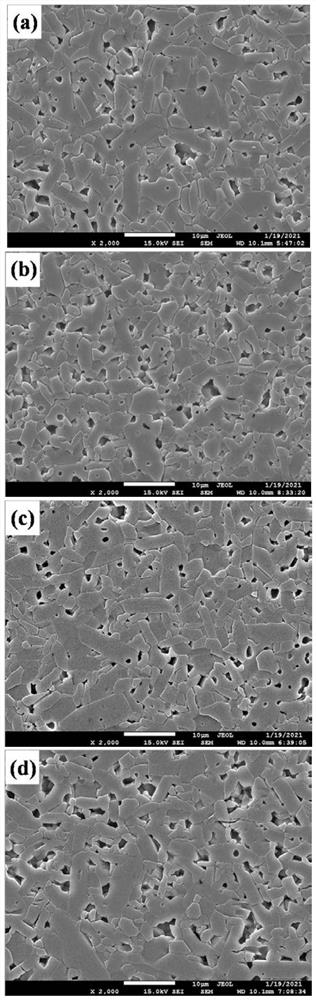

Image

Examples

Embodiment 1

[0041] The preparation method based on self-reinforced silicon carbide ceramic material comprises the following steps:

[0042] The powder is composed of: α-SiC powder: 95%, B 4 C powder: 1.5%, carbon: 3.5%.

[0043] Among them, α-SiC powder >98.5%, particle size range is 0.3-1.5μm, B 4 C powder > 99%, particle size range 0.3-1.5μm, phenolic resin as carbon source and binder: carbon residue rate 52.5%.

[0044] Specific steps are as follows:

[0045] Step 1, ingredients: weigh α-SiC powder, B 4 C powder and phenolic resin;

[0046] Step 2, mixing: Put the weighed powder and the phenolic resin dissolved in ethanol into the ball mill tank, and mix them evenly by high-speed ball mill for use;

[0047] Select alumina balls as grinding balls, add ethanol for mixing, according to the ball, material and ethanol mass ratio of 2:1:1.5, the rotating speed is 100rpm, and the mixing time is 12 hours;

[0048]Step 3, drying: Dry the uniformly mixed powders in an oven at 85°C, grind t...

Embodiment 2

[0054] The preparation method based on self-reinforced silicon carbide ceramic material comprises the following steps:

[0055] The powder is composed of: α-SiC powder: 94%, β-SiC powder: 1%, B 4 C powder: 1.5%, carbon: 3.5%.

[0056] Among them, α-SiC powder>98.5%, particle size range is 0.3-1.5μm, β-SiC powder>99%, particle size range is 10-100nm, B 4 C powder > 99%, particle size range 0.3-1.5μm, phenolic resin as carbon source and binder: carbon residue rate 52.5%.

[0057] Specific steps are as follows:

[0058] Step 1, ingredients: weigh α-SiC powder, β-SiC powder, B 4 C powder and phenolic resin;

[0059] Step 2, mixing: Put the weighed powder and the phenolic resin dissolved in ethanol into the ball mill tank, and mix them evenly by high-speed ball mill for use;

[0060] Select alumina balls as grinding balls, add ethanol for mixing, according to the ball, material and ethanol mass ratio of 2:1:1.5, the rotating speed is 100rpm, and the mixing time is 12 hours;

...

Embodiment 3

[0067] The preparation method based on self-reinforced silicon carbide ceramic material comprises the following steps:

[0068] The powder is composed by mass percentage: α-SiC powder: 93%, β-SiC powder: 2%, B 4 C powder: 1.5%, carbon: 3.5%.

[0069] Among them, α-SiC powder>98.5%, particle size range is 0.3-1.5μm, β-SiC powder>98%, particle size range is 10-100nm, B 4 C powder > 99%, particle size range 0.3-1.5μm, phenolic resin as carbon source and binder: carbon residue rate 52.5%.

[0070] Specific steps are as follows:

[0071] Step 1, ingredients: weigh α-SiC powder, β-SiC powder, B 4 C powder and phenolic resin;

[0072] Step 2, mixing: Put the weighed powder and the phenolic resin dissolved in ethanol into the ball mill tank, and mix them evenly by high-speed ball mill for use;

[0073] Select alumina balls as grinding balls, add ethanol for mixing, according to the ball, material and ethanol mass ratio of 2:1:1.5, the rotating speed is 100rpm, and the mixing time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com