A kind of wear-resistant ultra-high performance concrete and preparation method thereof

An ultra-high-performance concrete technology, applied in the field of concrete, can solve the problems of high flexural strength, low strength, and high preparation cost, and achieve high compressive and flexural strength, strong impact resistance, and reduced cracking tendency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

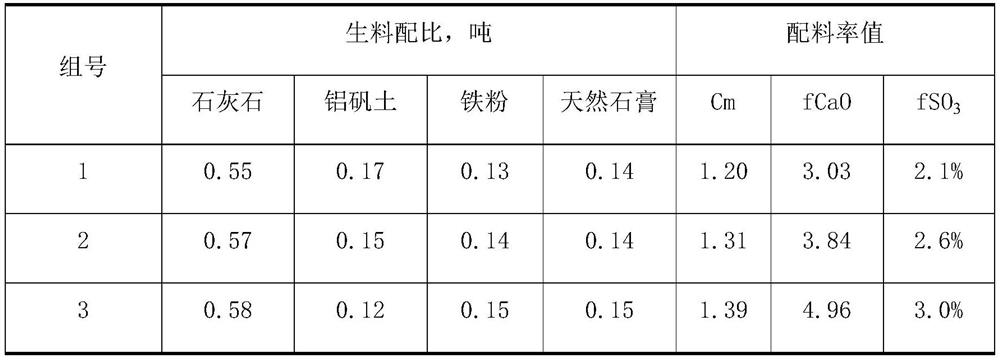

[0036] Example 1 Preparation of high-speed iron high-belite sulfoaluminate cement clinker powder

[0037] According to the raw meal weight ratio and batching rate value shown in Table 1, 1.0 ton of raw meal with a fineness of 0.08 mm and a sieve residue of less than 8% was obtained by grinding. 26% loss) of high-speed iron and high belite sulfoaluminate cement clinker, the specific surface area of 400 ~ 450m obtained after grinding 2 / kg of high-speed rail high-belite sulfoaluminate cement clinker powder.

[0038] Table 1 Raw meal ratio and ingredient ratio value

[0039]

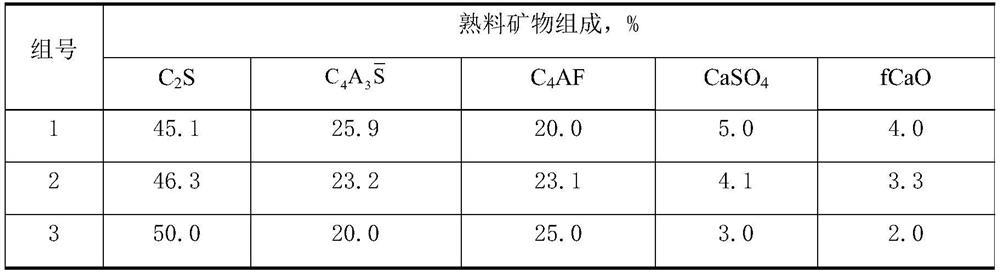

[0040] The mineral composition of the high-speed iron high-belite sulfoaluminate cement clinker is shown in Table 2.

[0041] Table 2 Mineral composition of high-speed rail high-belite sulfoaluminate cement clinker

[0042]

[0043] According to the standard GB17671-1999 "Test method for strength of cement mortar (ISO method)", GB / T1346-2011 "Test method for water consumption, setting time and st...

Embodiment 2

[0048] Example 2 Preparation of special gelling material

[0049] According to the weight ratio shown in Table 4, each component is added to the dry powder mixer in turn, and the special cementitious material for wear-resistant UHPC is obtained after fully and uniformly mixing.

[0050] Table 4 Weight ratio of special cementitious materials

[0051]

[0052] According to the standard GB17671-1999 "Test method for strength of cement mortar (ISO method)" and GB / T1346-2011 "Test method for water consumption, setting time and stability of cement standard consistency", the physical properties of the above-mentioned groups of special cementitious materials The wear resistance of cement mortar was measured according to JC / T421-2004 "Test method for abrasion resistance of cement mortar", and the results are shown in Table 5.

[0053] Table 5 Physical properties of special cementitious materials

[0054]

[0055]

[0056] It can be seen from Table 5 that the flexural strengt...

Embodiment 3

[0057] Example 3 Preparation of wear-resistant UHPC material

[0058] In this embodiment, the SiO in the silica fume 2 The content is more than 95%, and the specific surface area is not less than 20000m 2 / kg. Steel slag aggregate is the solid waste slag-steel slag produced by the metallurgical industry, which is crushed and screened to make the particle size reach ≥1.0mm and ≤3.0mm; -Iron tailings, obtained by drying and sorting, so that the particle size is ≥0.5mm and ≤1.0mm; quartz sand is washed and dried sand with particle size ≤0.5mm; water reducing agent is polycarboxylate high-efficiency reducing agent Water agent, the water reduction rate is more than 30%; the length of the copper-plated steel fiber is 10mm-15mm, and the diameter is 0.15mm-0.2mm.

[0059] Group number 1:

[0060] Each raw material component was weighed according to the following weights: 650g special cementitious material; 150g silica fume; 620g steel slag aggregate; 350g iron tailing sand; 250g q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com