Thermo-sensitive fluorocarbon surfactant, preparation method and application thereof

A fluorocarbon surface and active agent technology, applied in chemical instruments and methods, gel preparation, colloid chemistry, etc., can solve the problems of increasing cleaning channels, toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A thermosensitive fluorocarbon surfactant prepared by the following synthetic route:

[0068]

[0069] The preparation method of described thermosensitive fluorocarbon surfactant mainly comprises the steps:

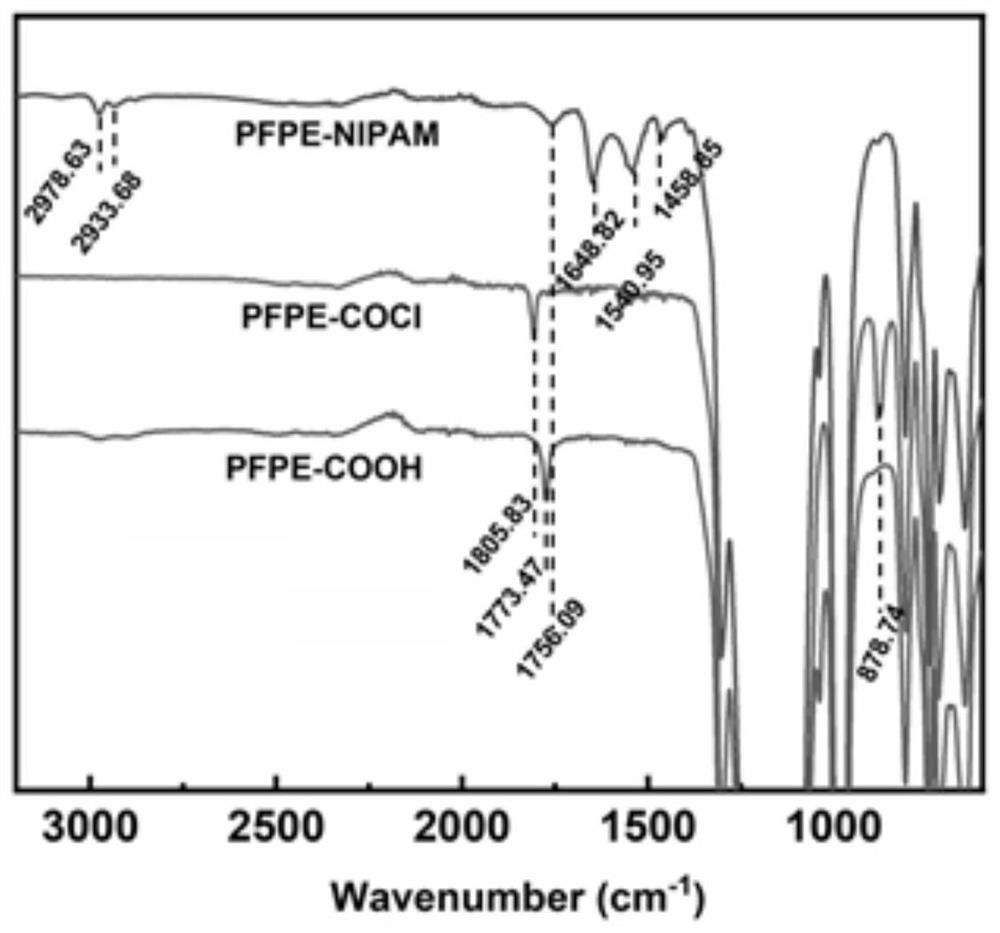

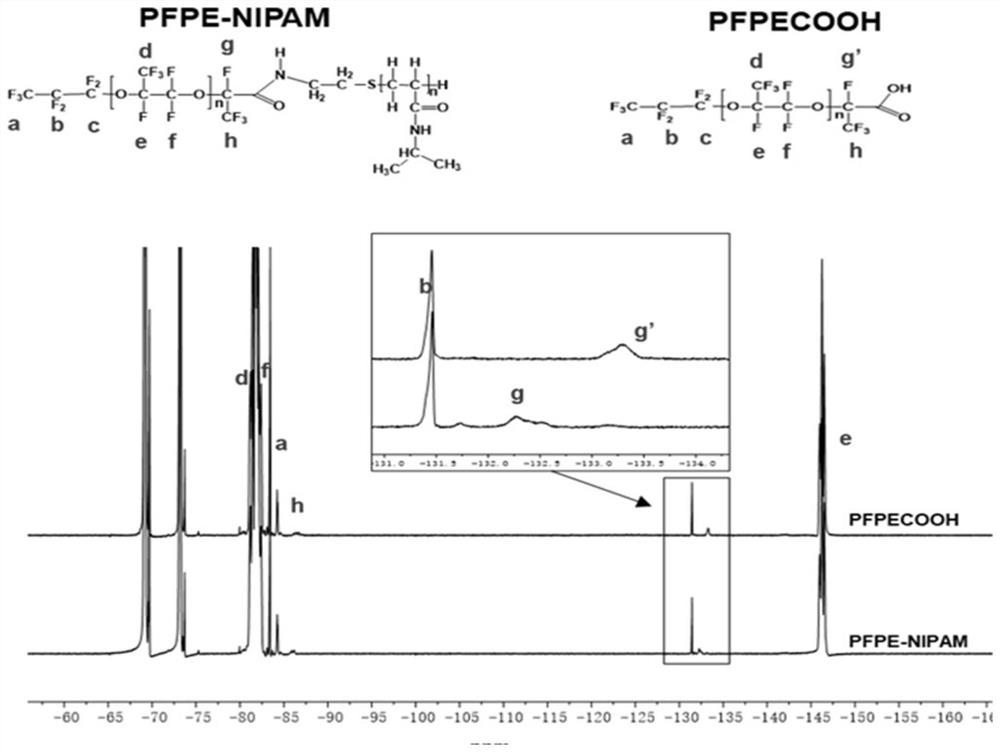

[0070] (1) Acylation: first weigh 22.5g of perfluoropolyether (PFPE-COOH) with carboxyl groups (DuPont, Krytoxl57FSH, average molecular weight is 6500) and dissolve it in 60ml of solvent fluorine oil (3M, Novec7100), then add 2.5ml of ethyl alcohol Diacyl chloride, under the protection of nitrogen, heated at reflux at 65°C for 48h; when the reaction mixture was cooled to room temperature, it was concentrated by distillation with a rotary evaporator to obtain acylated perfluoropolyether (PFPE-COC1), and the solvent and excess Oxalyl chloride;

[0071] (2) Reaction: Dissolve the PFPE-COCl obtained in step (1) in 30ml of Novec7100 and dichloromethane mixed solvent (Novec7100:dichloromethane volume ratio=1:2), under nitrogen protection, add 2.4g ammonia Blocked po...

Embodiment 2

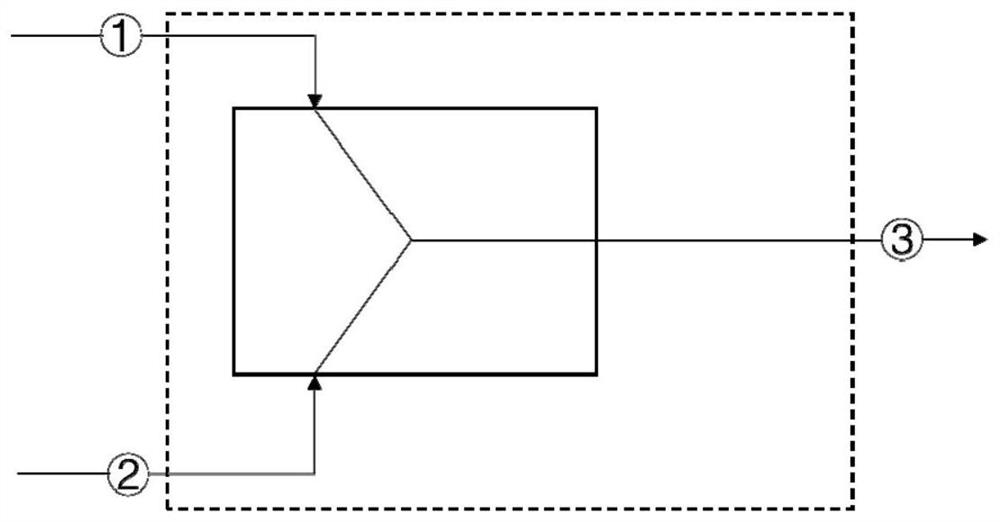

[0074] The thermosensitive fluorocarbon surfactant prepared by the present invention is added in the oil phase, by such as image 3 The microfluidic device shown prepares microgels, and the microfluidic device includes: ① first input channel, input alginic acid prepolymer solution, ② second input channel, input oil phase containing acid and surfactant, ③ for the output channel. The surface of the inner wall of the microchannel is treated with hydrophobicity.

[0075]Dissolve fluorescein-labeled sodium alginate in cell culture medium containing phenol red to prepare a sodium alginate content of 1% (w / v), as the water phase of the water-in-oil emulsion, and enter ① the first input channel. The mixed solution obtained by adding the temperature-sensitive fluorocarbon surfactant and acetic acid into the fluorinated oil Novec HFE7100, as the oil phase of the water-in-oil emulsion system, enters the second input channel of ②. The temperature-sensitive fluorocarbon surfactant in the...

Embodiment 3

[0077] The temperature-sensitive fluorocarbon surfactant prepared by the present invention is added into the oil phase, and a microgel is prepared through a microfluidic device, such as Figure 7 As shown, including ① first input channel, input alginic acid prepolymer solution, ② second input channel, input oil phase containing acid and surfactant, ③ third input channel, input pure water or buffer solution; ④ is output channel. The surface of the inner wall of the microchannel is treated with hydrophobicity.

[0078] Dissolve fluorescein-labeled sodium alginate in deionized water to obtain a sodium alginate content of 1% (w / v), then add a final concentration of 50 mM calcium ethylenediaminetetraacetic acid (Ca-EDTA) chelate aqueous solution ; Use the gel prepolymer solution configured above as the water phase of the water-in-oil emulsion, and enter ① the first input channel. The mixed solution obtained by adding the temperature-sensitive fluorocarbon surfactant and acetic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com