Oxide-reinforced low-activation steel and manufacturing method thereof

A technology of low activation steel and manufacturing method, applied in the field of iron and steel metallurgy, can solve the problems of high cost, low efficiency, difficult to produce oxide-strengthened steel, etc., and achieves the improvement of anti-He brittle ability, strong effect and high temperature mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

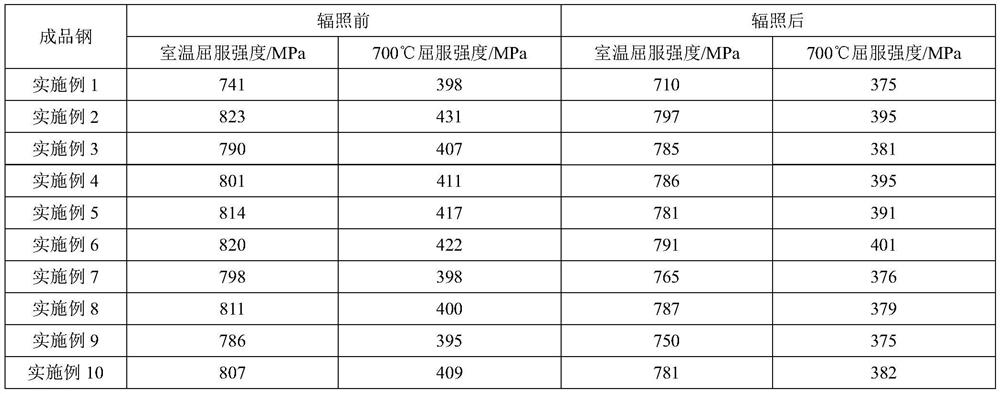

Examples

Embodiment 1

[0043] The manufacturing method of the oxide-reinforced low-activation steel of this embodiment comprises the following steps:

[0044] (1) Ultra-pure smelting of rare earth-rich steel: use a vacuum induction furnace to smelt according to the chemical composition of 9Cr2WVTa steel, and wait until the composition of the low-activation steel reaches the standard (and the mass fraction of oxygen in the steel is less than 10×10 -6 ) to add Ti pure metal, after the Ti metal is melted, add rare earth Y, after adding rare earth Y, carry out 300kW power stirring and refining for 15min, and then carry out tapping and casting into steel ingots; wherein, the amount of Ti added is 0.25% of the mass of the low-activation steel ; The amount of Y added is 0.5% of the low-activation steel mass;

[0045] (2) Pretreatment of low-activation steel: place the steel ingot at 1200 ° C for 3 hours, and then roll it into a wire rod with a diameter of 5 mm for use; during the rolling process, the start...

Embodiment 2

[0050] The manufacturing method of the oxide-reinforced low-activation steel of this embodiment comprises the following steps:

[0051] (1) Ultra-pure smelting of rare earth-rich steel: use a vacuum induction furnace to smelt according to the chemical composition of 9Cr2WVTa, and wait until the composition of the low-activation steel reaches the standard (and at this time the mass fraction of oxygen in the steel is less than 10×10 -6 ) to add Ti pure metal, after the Ti metal is melted, add rare earth Y, after adding rare earth Y, carry out 500kW power stirring and refining for 10min, and then carry out tapping and casting into steel ingots; wherein, the amount of Ti added is 0.5% of the mass of the low-activation steel ; The amount of Y added is 1% of the low-activation steel mass;

[0052] (2) Pretreatment of low-activation steel: place the steel ingot at 1250°C for 2 hours, and then roll it into a wire rod with a diameter of 10mm for use; during the rolling process, the sta...

Embodiment 3

[0057] The manufacturing method of the oxide-reinforced low-activation steel of this embodiment comprises the following steps:

[0058] (1) Ultra-pure smelting of rare earth-rich steel: use a vacuum induction furnace to smelt according to the chemical composition of 9Cr2WVTa steel, and wait until the composition of the low-activation steel reaches the standard (and the mass fraction of oxygen in the steel is less than 10×10 -6 ) to add Ti pure metal, after the Ti metal is melted, add rare earth Y, after adding rare earth Y, carry out stirring and refining with 400kW power for 13min, and then carry out tapping and casting into steel ingots; wherein, the amount of Ti added is 0.35% of the mass of the low-activation steel ; The amount of Y added is 0.65% of the low-activation steel mass;

[0059] (2) Pretreatment of low-activation steel: place the steel ingot at 1230°C for 2.5 hours, and then roll it into a wire rod with a diameter of 7mm for use; during the rolling process, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com