Preparation method of ceramic surface supported catalytic filler

A technology of catalytic packing and ceramic surface, which is applied in the cross-application field of materials and chemical engineering, can solve the problems of large transmission resistance of catalytic packing, uneven distribution of vapor and liquid, etc., and achieve the effects of improved catalyst efficiency, uniform liquid distribution, and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the present invention comprises the following steps:

[0030] (1) Wash the commercially purchased 3mm ceramic Raschig ring packing with 10% sodium hydroxide solution at 70-85°C for 12h, wash with water until neutral, and dry at 100°C for 24h before use;

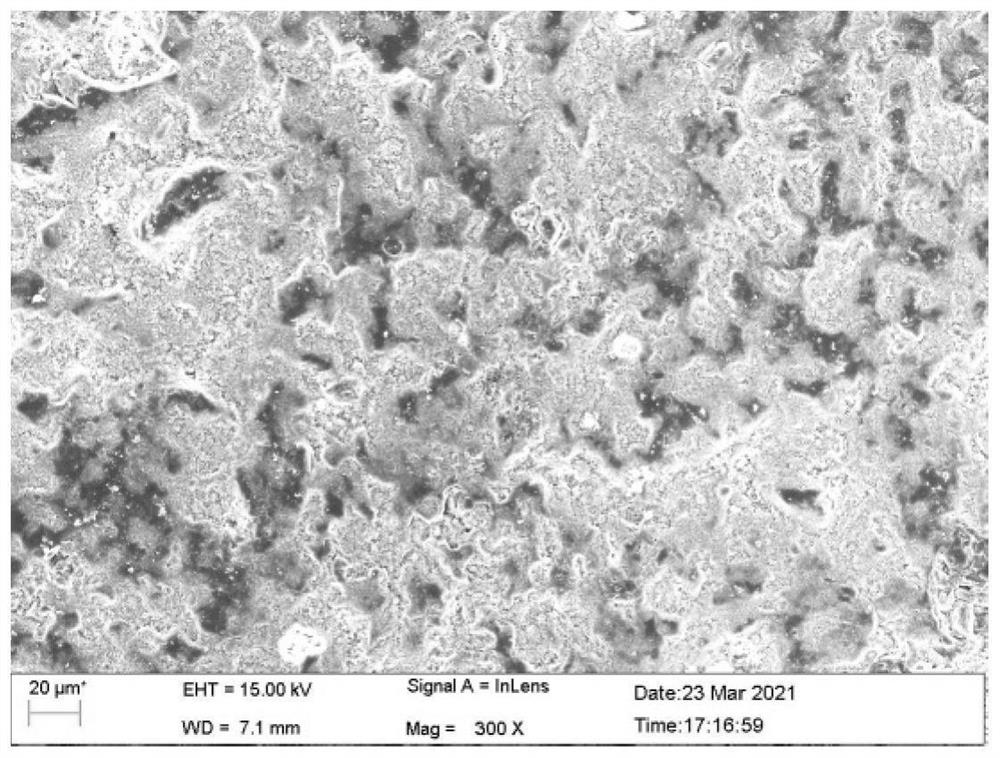

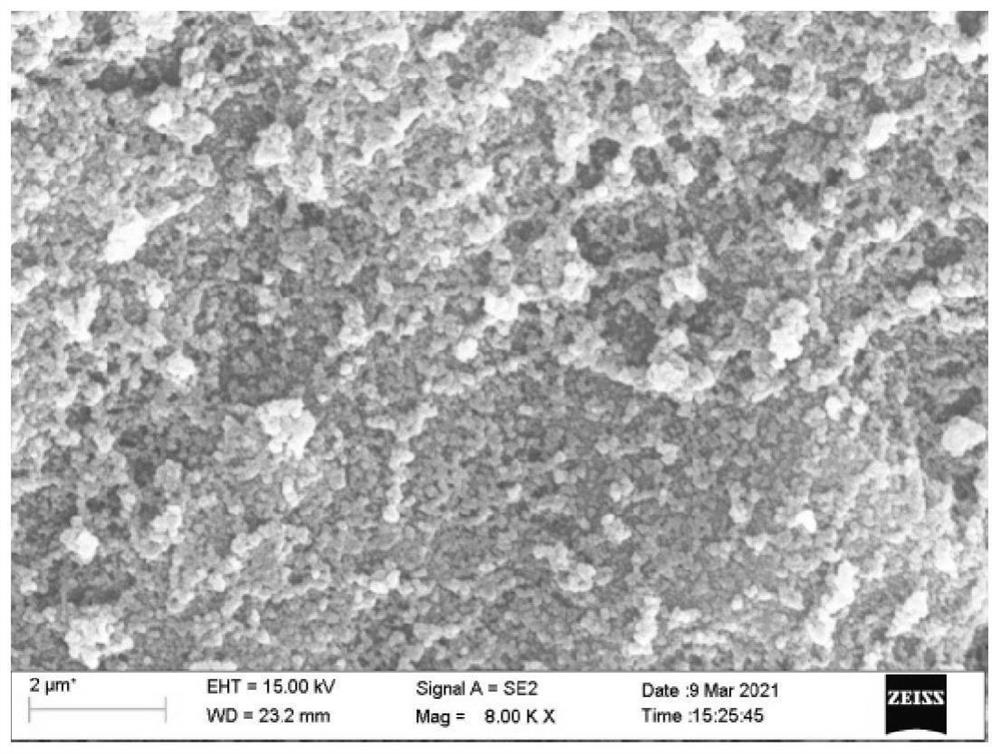

[0031] (2) Configure Tris-HCl buffer solution with pH = 8.0-9.0, compound it with absolute ethanol at 3-6:1, soak the Raschig ring obtained in step (1), and add a certain amount of mono Nitric acid, aminosilane, vinylsilane, shake at room temperature for 8-18 hours to hydrolyze and oxidize under weak alkaline conditions, form small balls and deposit on the ceramic surface, and then raise the temperature to 65-80°C to cross-link the small balls to form a coating Layer, after absolute ethanol cleaning, obtains the Raschig ring that the surface has been treated;

[0032] (3) Configure a compound solution of vinylimidazole, cross-linking agent and initiator in a certain proportion, and after stir...

Embodiment 1

[0037] Prepare a compound solution of 30ml Tris-HCl buffer (pH=8.5) + 10ml ethanol in a conical flask, add 30g of Raschigcycline after alkali washing, shake it well, add 100mg of tannic acid, 1.5μL of γ-aminopropyl Triethoxysilane and 3 μL of vinyltriethoxysilane were shaken at room temperature for 18 hours, and then the solution was heated to 75° C. for 3 hours.

[0038] Take 0.68g of vinylimidazole, 0.4g of divinylbenzene, 0.08g of azobisisobutyronitrile, and 5g of treated Raschig rings, mix them evenly, use a circulating water vacuum pump to evacuate, and beat and oscillate on the rubber pad several times. After there are no obvious bubbles in the system, put the Raschig ring into a 50ml autoclave, add 30ml of ethyl acetate, react at 100°C for 24h, and then dry at room temperature for 24h.

[0039] Put the dry Raschig ring into the Erlenmeyer flask, add toluene to completely submerge it, add 1.5g propane sultone, react at 80°C for 24 hours, and then exchange it with 1mol / L ...

Embodiment 2

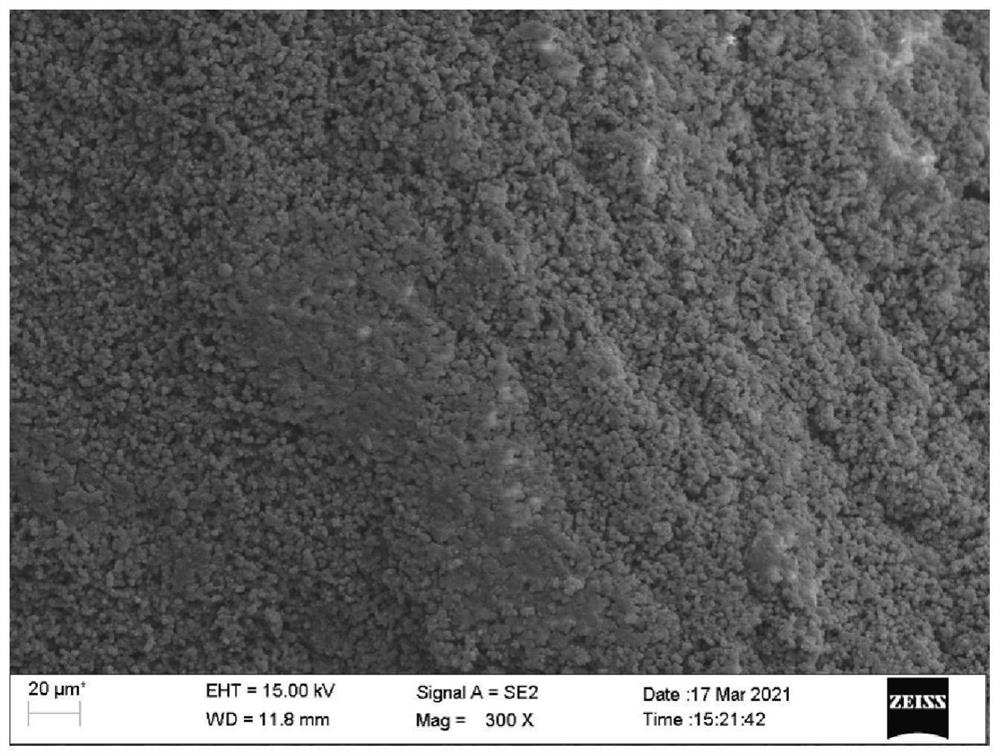

[0041] Prepare a compound solution of 30ml Tris-HCl buffer (pH=8.5) + 10ml ethanol in a conical flask, add 30g of alkali-washed Raschigcycline, shake well, add 100mg of tannic acid, 1.5μL of γ-aminopropyl Triethoxysilane, 3 μL vinyltriethoxysilane, after shaking at room temperature for 18 hours, the solution was heated to 75°C for 3 hours.

[0042]Take 1.68g of vinylimidazole, 0.6g of divinylbenzene, 0.08g of azobisisobutyronitrile, and 5g of treated Raschig rings and mix them evenly, then use a circulating water vacuum pump to evacuate, and beat and vibrate on the rubber pad several times , after there are no obvious bubbles in the system, put the Raschig ring into a 50ml autoclave, add 30ml ethyl acetate, react at 100°C for 24h, and then dry at room temperature for 24h.

[0043] Put the dry Raschig ring into the Erlenmeyer flask, add toluene to completely immerse it, add 2g of butane sultone, react at 80°C for 24 hours, and then exchange it with 1mol / L sulfuric acid for 24 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com