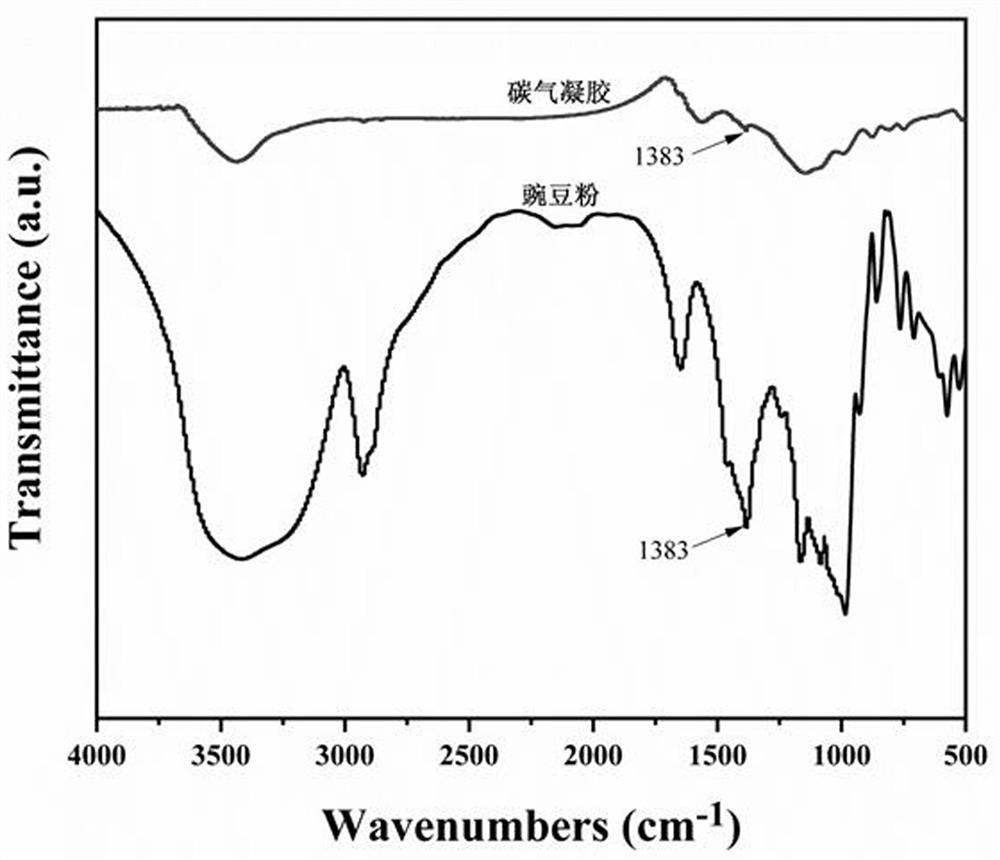

Boron nitride/pea meal double-heat-conduction-base carbon aerogel as well as preparation method and application thereof

A technology of carbon airgel and boron nitride, which is applied in the direction of airgel preparation, carbon preparation/purification, chemical instruments and methods, etc., can solve the problem of inconvenient impregnation of polyethylene glycol, small amount of adsorbed phase change materials, Small specific surface area and other issues, to achieve the effect of maintaining high phase change latent heat characteristics, reducing density, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

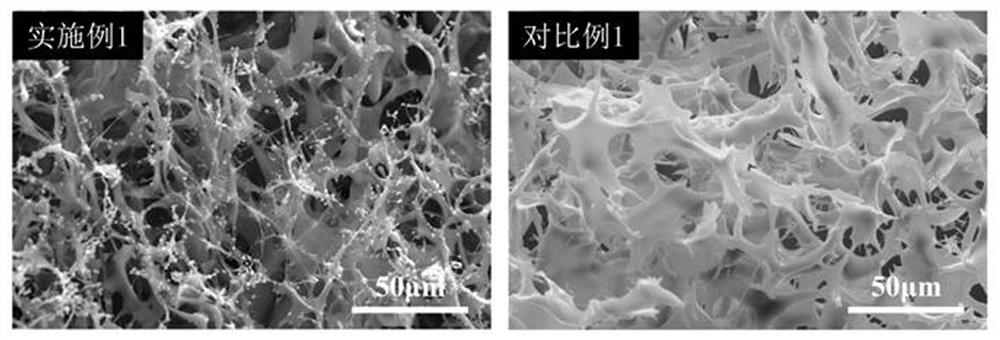

Embodiment 1

[0061] A kind of boron nitride addition is the preparation method of the boron nitride / pea flour double thermal conduction base carbon airgel of 13%, comprising the following steps:

[0062] Step 1) Preparation of modified two-dimensional nanosheet boron nitride, 3 g of boron nitride was placed in 300 mL of deionized water and cyclohexane mixed solution, and the nitriding The boron was modified and stripped for 12 h. After the reaction was completed, the obtained product was filtered, then dried at 80 °C for 24 h, and ground to obtain the modified two-dimensional nanosheet boron nitride;

[0063] Step 2) Preparation of carbon airgel with boron nitride / pea flour dual heat-conducting bases. Firstly, mix the modified two-dimensional nanosheet boron nitride obtained in step 1 with 150 mL deionized water and sonicate for 30 min to obtain a boron nitride solution , at the same time, the pea flour was magnetically stirred with diammonium hydrogen phosphate and deionized water with a ...

Embodiment 2

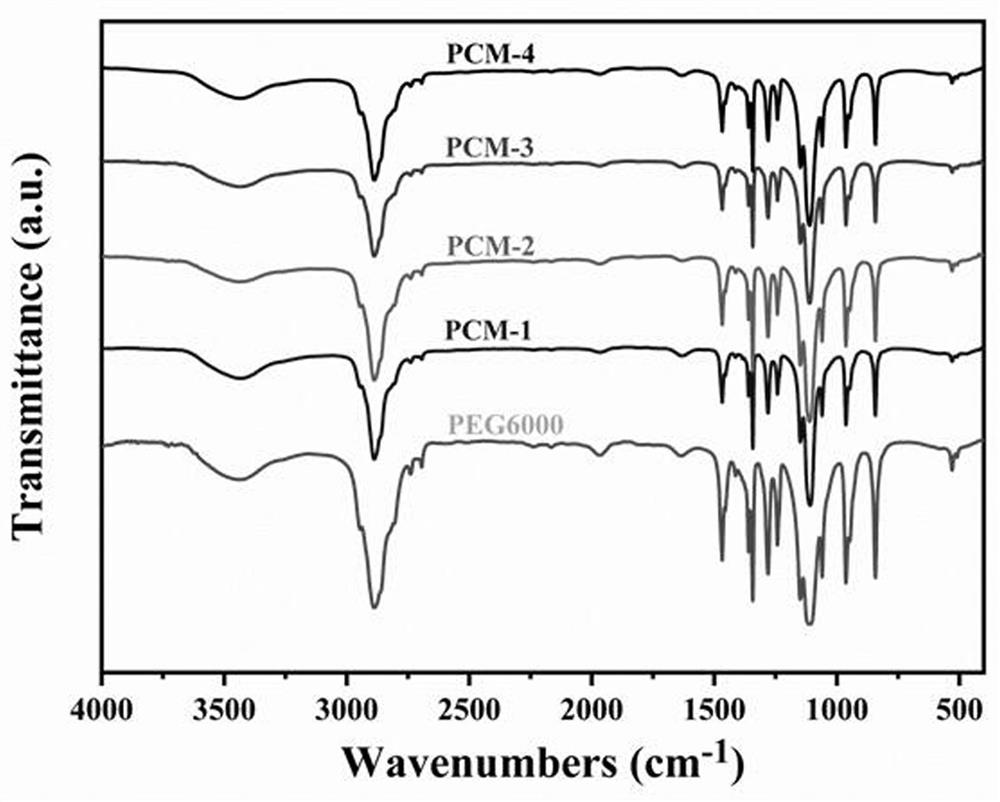

[0097] A method for preparing a boron nitride / pea flour double heat-conductive carbon aerogel with a boron nitride addition of 29%. The solute quality of two-dimensional nanosheet boron nitride is 29% of the solute quality of pea flour.

[0098] In order to prove the application effect of boron nitride / pea flour double thermal conductivity carbon airgel with boron nitride addition of 29% as a phase change material, vacuum impregnation method was used to prepare boron nitride addition of 29% Boron / pea flour double thermal conductivity carbon airgel composite phase change material, the obtained sample is named PCM-4.

[0099] Calculation of the mass of boron nitride / pea flour double thermal conductivity carbon airgel before and after impregnation shows that when the solute mass of boron nitride is 29% of the solute mass of pea flour, 6.321 g of phase change material polyethylene glycol will be adsorbed. Therefore, the adsorption amount of the phase change material in PCM-4 is 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com