A high temperature resistant connecting layer primer and its preparation method and application

A connecting layer and high temperature resistant technology, which is applied in mechanical equipment, friction linings, etc., can solve the problems of high temperature resistance difference defects, failure to meet the braking requirements of 450km/h high-speed trains, etc., achieve good bonding strength and avoid failure risks , to avoid the effect of corrosion failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

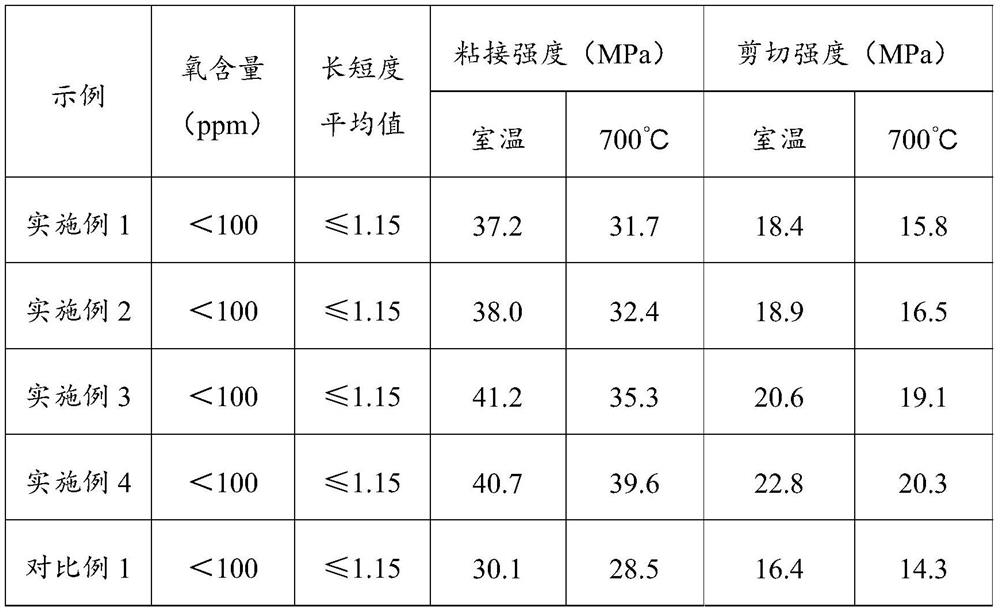

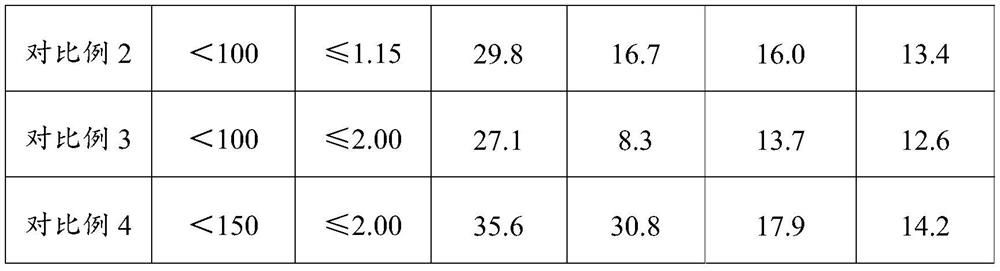

Examples

Embodiment 1

[0032] This embodiment provides a high temperature resistant connection layer primer, the components of which include 15wt% Ni, 15wt% Fe, 0.5wt% Mo, 0.2wt% Nb, 1wt% Cr, and the balance is copper.

[0033] The preparation method of the above-mentioned connecting layer primer comprises the following steps,

[0034] Before smelting, all raw materials were pickled to remove surface oxides, placed at 50°C for 30min, and dried. Add Ni-Mo master alloy, Ni-Nb master alloy, Cr block, Ni block, Fe block, and Cu block into the smelting furnace in order from bottom to top. After all the raw materials are melted, the temperature is raised to 1500 ℃, add graphite blocks, keep the temperature for 30min, and use electromagnetic stirrer to stir at the same time to achieve alloying and fully deoxidize, then cool to 1000℃, fill with argon, and pour the master alloy to obtain consumable electrode rods. Wherein, the added amount of graphite blocks is 0.3 wt % of the total amount of raw materials ...

Embodiment 2

[0037] This embodiment provides a high temperature resistant connection layer primer, the components of which include 24wt% Ni, 24wt% Fe, 0.5wt% Mo, 0.1wt% Nb, 3wt% Cr, and the balance is copper.

[0038] The preparation method of the above-mentioned connecting layer primer comprises the following steps,

[0039]Before smelting, all raw materials were pickled to remove surface oxides, placed at 50°C for 30min, and dried. Add Ni-Mo master alloy, Ni-Nb master alloy, Cr block, Ni block, Fe block, and Cu block into the smelting furnace in order from bottom to top. After all the raw materials are melted, the temperature is raised to 1500 ℃, add graphite blocks, keep the temperature for 30min, and use electromagnetic stirrer to stir at the same time to achieve alloying and fully deoxidize, then cool to 1000℃, fill with argon, and pour the master alloy to obtain consumable electrode rods. Wherein, the added amount of graphite blocks is 0.3 wt % of the total amount of raw materials o...

Embodiment 3

[0042] This embodiment provides a high temperature resistant connection layer primer, the components of which include 20wt% Ni, 20wt% Fe, 1wt% Mo, 1wt% Nb, 1.5wt% Cr, and the balance is copper.

[0043] The preparation method of the above-mentioned connecting layer primer comprises the following steps,

[0044] Before smelting, all raw materials were pickled to remove surface oxides, placed at 50°C for 30min, and dried. Add Ni-Mo master alloy, Ni-Nb master alloy, Cr block, Ni block, Fe block, and Cu block into the smelting furnace in order from bottom to top. After all the raw materials are melted, the temperature is raised to 1500 ℃, add graphite blocks, keep the temperature for 30min, and use electromagnetic stirrer to stir at the same time to achieve alloying and fully deoxidize, then cool to 1000℃, fill with argon, and pour the master alloy to obtain consumable electrode rods. Wherein, the added amount of graphite blocks is 0.4 wt % of the total amount of raw materials fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com