Silicon oxide single-coated cesium-copper-chlorine quantum dot, and preparation method and application thereof

A single cesium copper chloride, quantum dot technology, applied in the field of quantum dots, can solve the problems of quantum dot performance impact and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

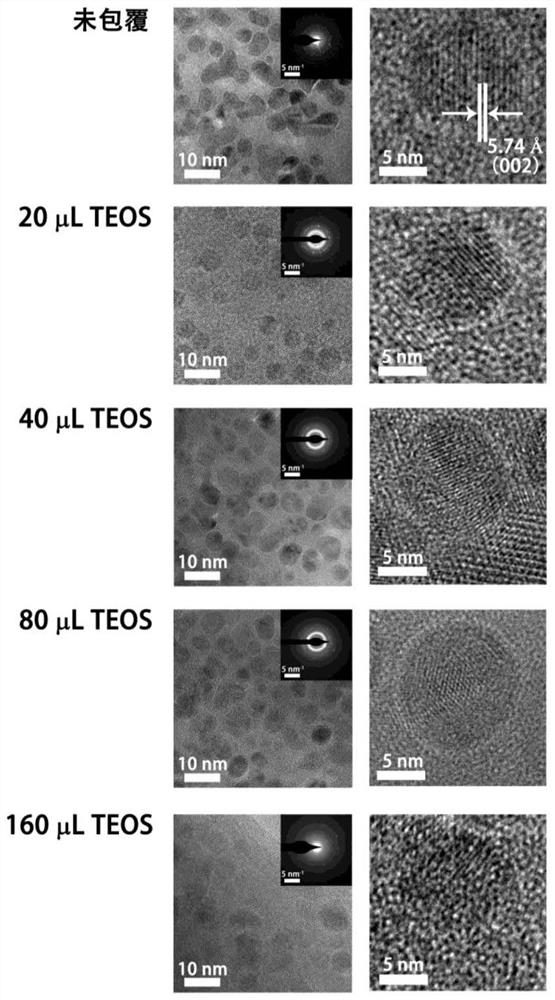

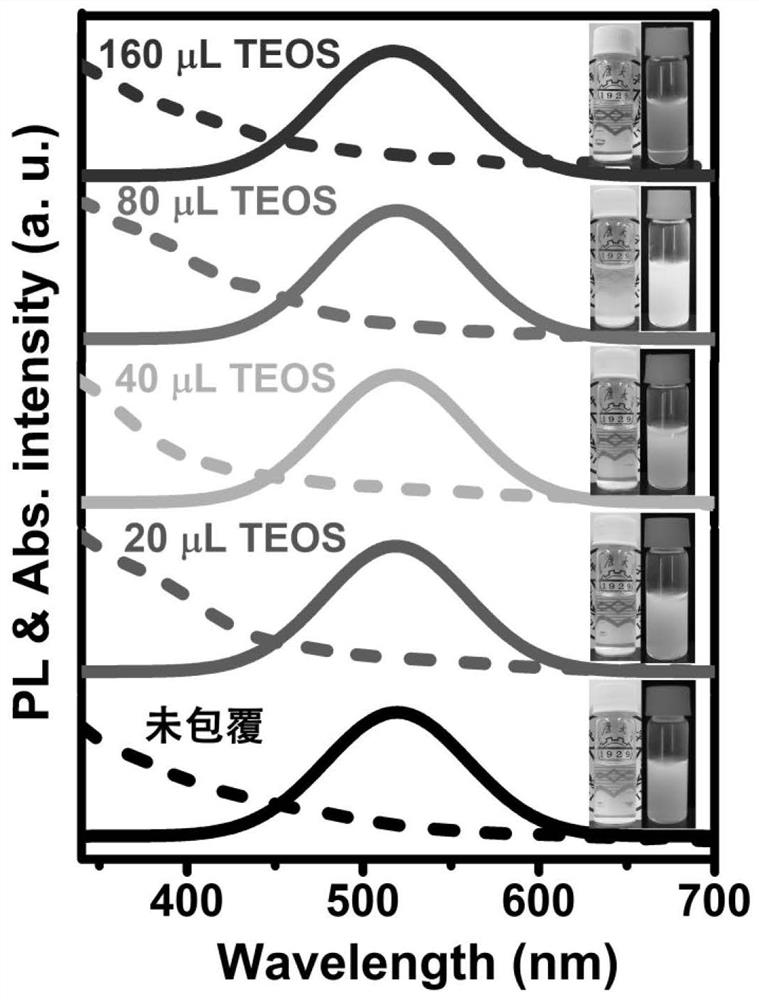

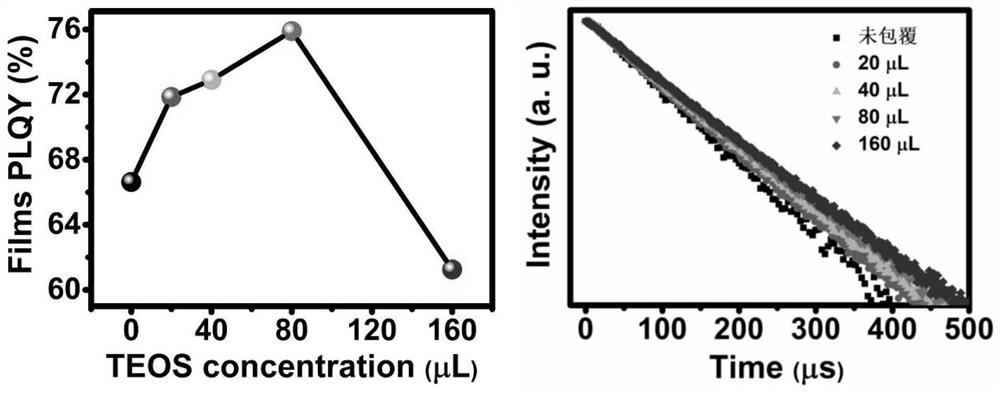

[0040]Preparation of SiO single-coated cesium copper chloride quantum dots (Cs 3 Cu 2 Cl 5 @SiO X )

[0041] (1) Preparation of cesium oleate precursor solution: 204mg Cs 2 CO 3 and 0.67mL of oleic acid were dissolved in 10mL of octadecene, and after nitrogen degassing for 20min, the temperature was raised to 120°C and kept for 30min to make Cs 2 CO 3 Complete reaction with oleic acid to obtain cesium oleate precursor;

[0042] (2) Preparation of cesium copper chloride quantum dots: add 39.6mg CuCl to 10mL octadecane, degas nitrogen for 20min, then raise the temperature to 120°C, then add 0.5mL oleylamine and 0.5mL oleic acid, and keep at 120°C for 5min Dissolve CuCl completely, then inject 3 mL of the cesium oleate precursor solution prepared in step (1), stir and react for 30 s and immediately put it into an ice bath for rapid cooling to obtain cesium copper chloride quantum dots;

[0043] (3) disperse the cesium copper chloride quantum dot prepared in step (2) in to...

Embodiment 2

[0045] Preparation of SiO single-coated cesium copper chloride quantum dots (Cs 3 Cu 2 Cl 5 @SiO X )

[0046] The difference from Example 1 is that in step (3), 80 μL of tetraethylsilane was added to obtain a reaction solution, and the molar ratio of cesium copper chloride quantum dots to tetraethylsilane in the reaction solution was 1:6.4.

Embodiment 3

[0057] Preparation of white light-emitting diodes (WLEDs) with silicon oxide single-clad cesium copper chloride quantum dots prepared in Example 2

[0058] 1) According to the mass ratio of 1:50, the commercial CaAlSiN 3 :Eu 2+ Mix the red phosphor with A / B glue (the mixing ratio of A / B glue is 1:4), stir for 15 minutes to get a dispersion, drop the dispersion onto a commercial UV chip, and dry it in vacuum at 90°C Cured in the box for 1 hour to obtain a cured chip;

[0059] 2) Dissolve polymethyl methacrylate in toluene at a mass volume ratio of 10:1, stir at 50°C for 2 hours to obtain a polymethyl methacrylate toluene solution, and wrap the silicon oxide prepared in Example 2 in a single Cesium-copper-chloride quantum dots are dispersed in polymethyl methacrylate toluene solution, then drop-coated on the cured chip described in step (1), and dried at 50°C for 15 minutes.

[0060] Figure 7 The electroluminescence and CIE results graphs of WLEDs at different voltages and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com