System and method for extracting various valuable elements in paigeite

A valuable element, boronite technology, applied in borates, boron oxides, iron oxide/iron hydroxide, etc., can solve problems such as environmental pollution and land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

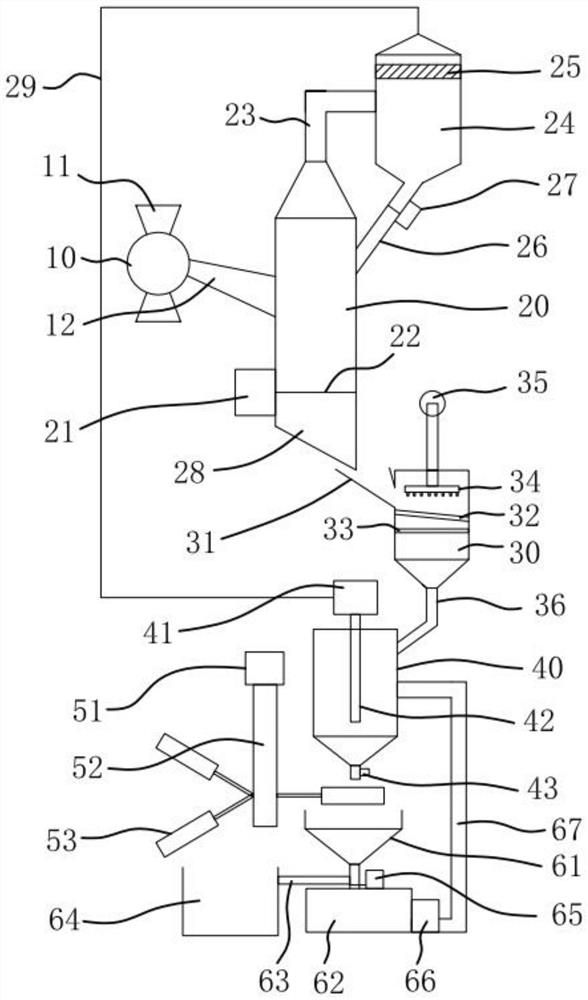

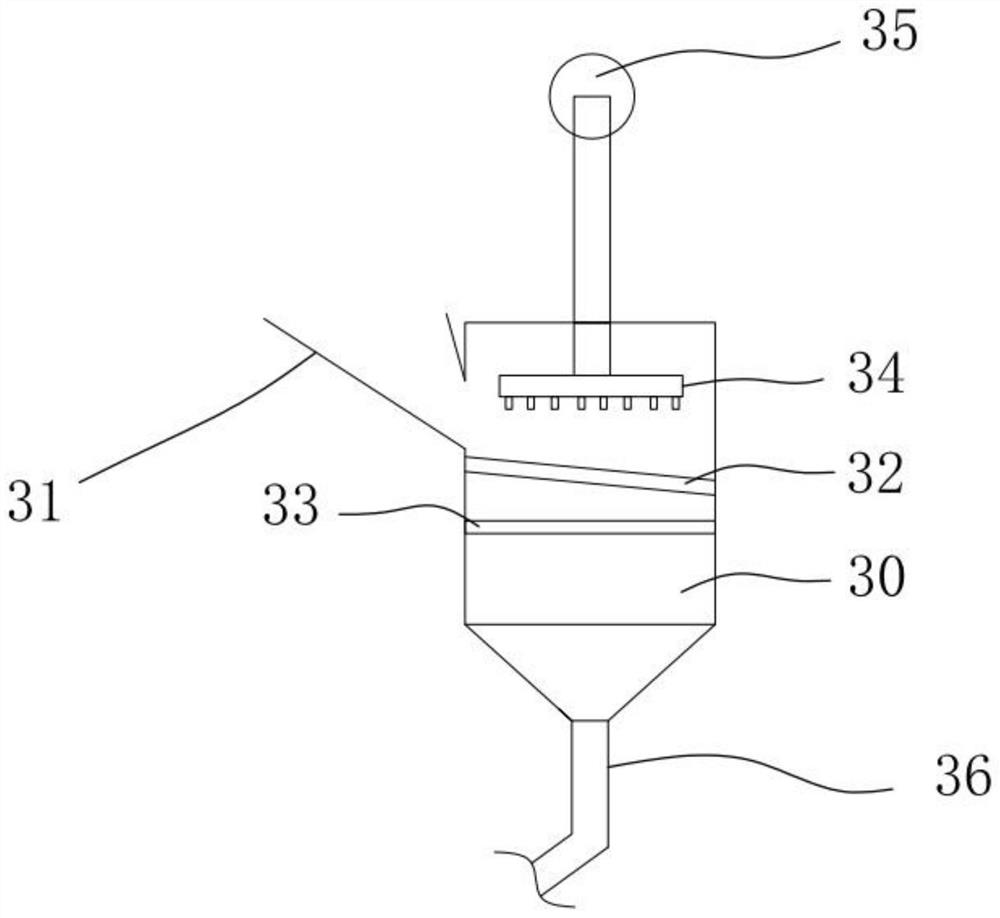

[0032] Such as figure 1 , figure 2 As shown, a system proposed in the present embodiment is extracted in a variety of price elements in boronite, including a pulverizer 10, a vertical calcination furnace 20, a water shower pad 30, a pelletizer 40, a filtration device, and a return According to the device, wherein the pulverizer 10 has a pulverizing machine feed port 11 and a pulverizing machine outlet portion 12, a pulverizing machine outlet port 12 and a side wall in which the vertical calcination furnace 20 is connected, and the pulverizing machine outlet 12 is baked. The connection of the side wall of the furnace 20 has a gates that control the open and closed.

[0033] The vertical calcination furnace 20 also includes a flue gas pipe 23, a filter tower 24, a first filter layer 25, a reintening tube 26, a vertical calcining furnace discharge port 28, and the ammonia pipe conduit 29, and the lower portion of the vertical calcination furnace 20 has The baked position, the upper e...

Embodiment 2

[0044] This embodiment proposes a method for extracted a variety of price element extraction in boronite ore, using a system extracted in a variety of price elements in the boron iron ore as presented in Example 1.

[0045] According to the chemical composition, mineral composition and thermodynamic analysis of boronite ore, the process flow of ammonium ammonium sulfate roast boronite:

[0046] The abrasive boron iron ore is mixed with ammonium sulfate, iron, aluminum, magnesium, boron in boron ore reactively generate soluble salts, silicon generates silica to be soluble in water; roasting flue gas dust removal Got ammonium sulfate solid, return to mix, recycle;

[0047] Excessive ammonia is used for sinking iron, Shen aluminum, Shen magnesium;

[0048] After the calcination is dissolved, the silica is dissolved in water, and the filtration is separated from sulfuric acid dissolved in water;

[0049] The filtrate uses ammonia regulation pH to sink iron, Shen aluminum, Shen magnesi...

Embodiment 3

[0053] In conjunction with Examples 1 and Example 2, specifically, the specific use process of the device is as follows:

[0054] In boronite, iron content is about 30%, including B 2 O 3 10%, MGO 30%, SIO 2 20%, Al 2 O 3 About 5%, boronite and ammonium ammonium sulfate ore is inserted to the pulverizing machine immersion port 11, the boron iron ore is pulverized to the boronite powder between the particle diameter of 80 μm, and the pulverized boron iron ore is discharged through the pulverizer. The port 12 entered the vertical calcination furnace 20, which dropped to the calcination flap 22, and mixed with ammonium sulfate and boronite powder in the above process. The vertical bolt furnace 20 is calcined to boron iron powder and ammonium sulfate powder to produce ammonia gas and ammonium sulfate powder, and the resulting flue gas enters the filter tower 24 through the flue gas pipe 23. Ammonium sulfate powder in the flue gas was filtered through the first filter layer 25, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com