Anti-blocking filtering basin and working method thereof

A filter tank and filter technology, applied in the direction of filtration separation, separation method, filtration circuit, etc., can solve the problems of inability to distribute and filter silt, difficult operation, filter clogging, etc., to reduce the possibility of system fouling and simplify operation Effect of maintenance process, reduction of burden and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing:

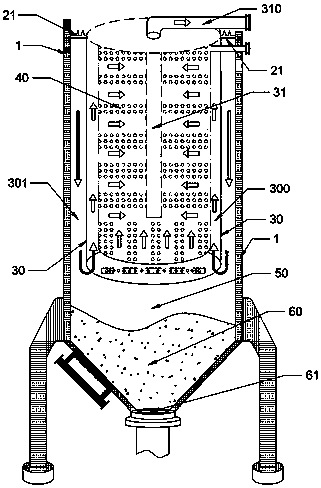

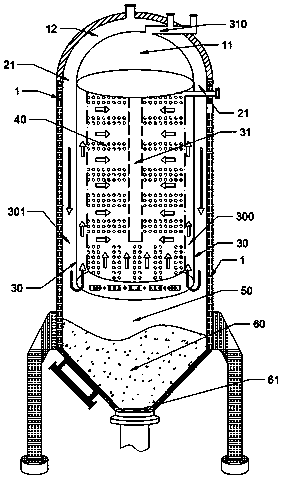

[0039] An anti-clogging filter tank, comprising a filter tank 1; the inside of the filter tank 1 is provided with a flow direction partition cover 30;

[0040] The space between the flow partition cover 30 and the filter tank 1 is a water flow down channel 301, and the upper part of the water flow down channel 301 is provided with a water inlet 21;

[0041] A filter 40 is provided in the flow partition cover 30 , and an opening is provided at the bottom of the flow partition cover 30 ; the space between the side wall of the partition cover 30 and the filter 40 is a water flow upward channel 300 ;

[0042] The inside of the filter 40 is a water collection channel 31, and the water collection channel 31 communicates with the outside of the filter tank 1 through the water production pipe 310;

[0043] The bottom of the filter tank 1 is a sludge collection area 60, and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com