Method for purifying and preparing beryllium hydroxide from beryllium fluoride-containing mixture

A technology containing beryllium fluoride and beryllium hydroxide, which is applied in the field of metal beryllium metallurgy, can solve the problems of high equipment investment requirements, large reagent volume, and limited purity of beryllium hydroxide, and achieve improved recovery rate, short process, and reduced slag volume. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A specific embodiment of the present invention discloses a method for purifying and preparing beryllium hydroxide from a mixture containing beryllium fluoride.

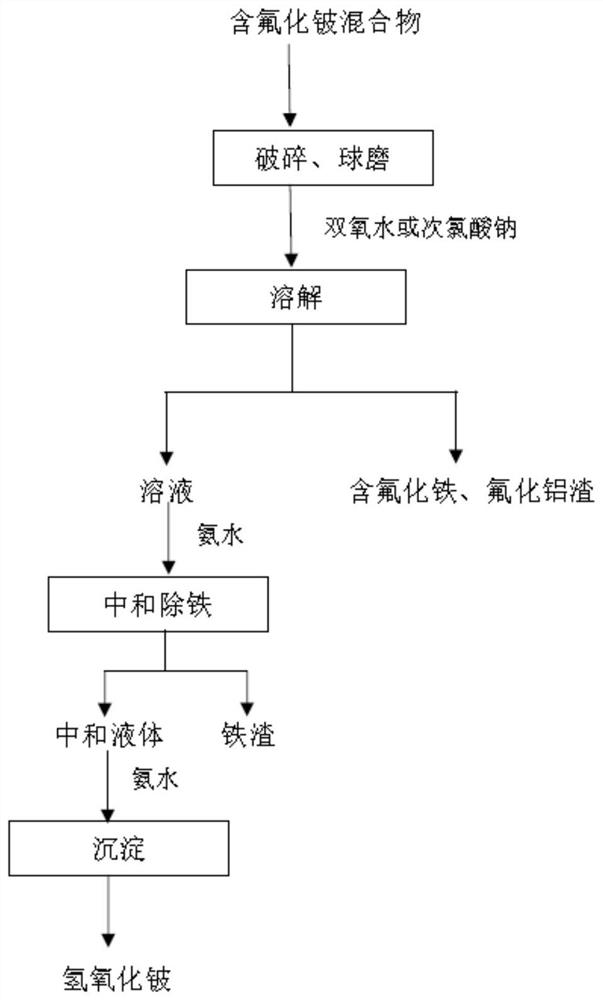

[0069] The main components of the beryllium fluoride-containing mixture used in the present invention are shown in Table 1. process such as figure 1 shown.

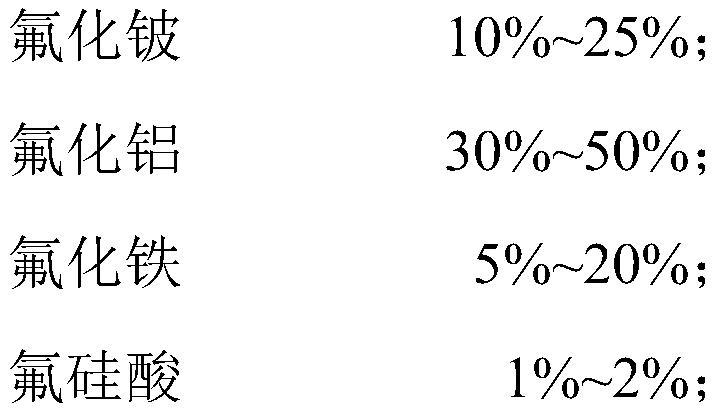

[0070] Table 1 The main components / wt% of the mixture containing beryllium fluoride

[0071] BeF 2

AlF 3

FeF 3

h 2 SiF 6

Crystal water and HF 17.5 39.8 10.4 1.5 remaining

[0072] Step 1. Use a crusher and a ball mill to grind 500 g of the beryllium fluoride-containing mixture to an average particle size of 100 microns.

[0073] Step 2. Add fine powder in the dissolution kettle, dissolve the beryllium fluoride-containing mixture with deionized water, add 100mL water, (the amount of water added is based on the BeF in 100mL water in the final solution) 2 The content of 87.5g is determined, that is, the liq...

Embodiment 2

[0080] A specific embodiment of the present invention discloses a method for purifying and preparing beryllium hydroxide from a mixture containing beryllium fluoride.

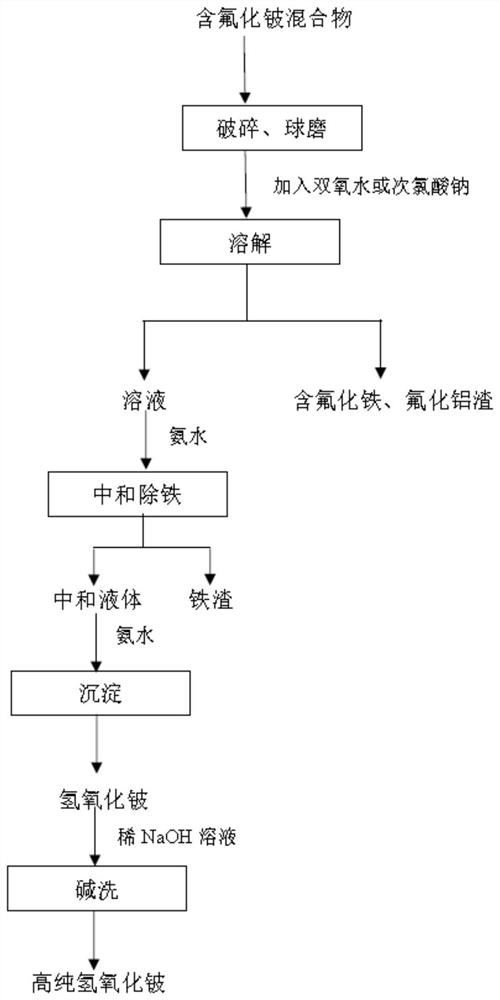

[0081] The beryllium fluoride-containing mixture used in the present invention comes from the intermediate product of microwave hydrofluoric acid leaching beryllium ore, and its main components are shown in Table 1. process such as figure 2 shown.

[0082] Step 1. Grinding 500 g of the beryllium fluoride-containing mixture to an average particle size of 50 microns in a crusher and a ball mill.

[0083] Step 2. Add fine powder in the dissolution kettle, dissolve the beryllium fluoride-containing mixture with deionized water, add 62.5mL water, (the amount of water added is based on the BeF in 62.5mL water in the final solution) 2 The content of 87.5g is determined, that is, the liquid-solid ratio of water to the mixed slag powder containing beryllium fluoride is 1:8 in mL / g);

[0084] The temperature of the s...

Embodiment 3

[0090] A specific embodiment of the present invention discloses a method for purifying and preparing beryllium hydroxide from a mixture containing beryllium fluoride.

[0091] The beryllium fluoride-containing mixture used in the present invention comes from the intermediate product of microwave hydrofluoric acid leaching beryllium ore, and its main components are shown in Table 1. process such as figure 2 shown.

[0092] Step 1. Grind 500 g of the beryllium fluoride-containing mixture to an average particle size of 60 microns in a crusher and a ball mill.

[0093] Step 2. Add fine powder in the dissolution kettle, dissolve the beryllium fluoride-containing mixture with deionized water, add 200mL water, (the amount of water added is based on the BeF in 200mL water in the final solution) 2 The content of 87.5g is determined, that is, the liquid-solid ratio of water to the mixed slag powder containing beryllium fluoride is 1:2 in mL / g);

[0094] The temperature of the soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com