A Heat Treatment Process for Improving the Strength and Plasticity of Cast Beryllium Aluminum Scandium Zirconium Alloy

A technology of zirconium alloy and beryllium aluminum, which is applied in the field of non-ferrous metals, can solve the problems of segregation of solute elements and coarse second phase, and achieve the effects of improving mechanical properties, elastic modulus and tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

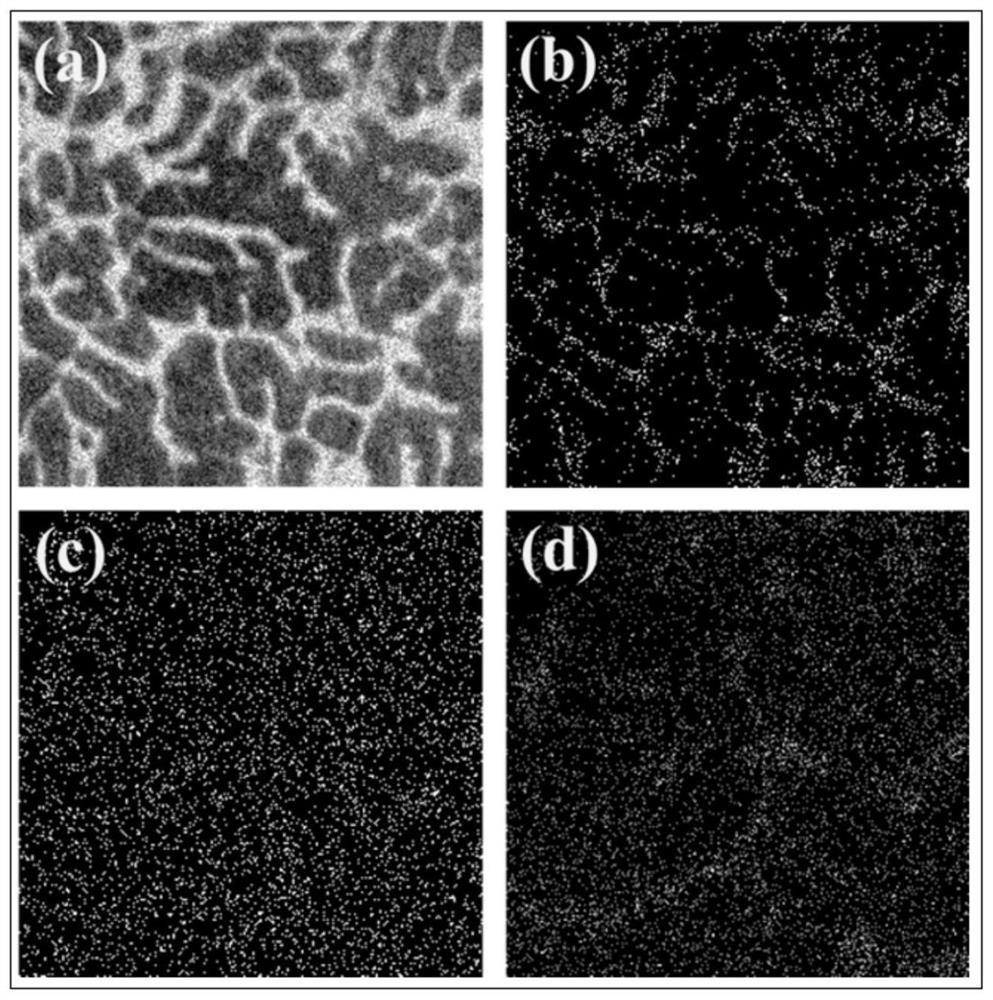

Image

Examples

Embodiment 1

[0025] A heat treatment process for improving the strength and plasticity of cast beryllium-aluminum-scandium-zirconium alloys. The alloy components include: 62% beryllium, 37% aluminum, 0.5% scandium, 0.5% zirconium, and the rest are unavoidable impurities. The total mass is 100%. The sum of the content is 100%.

[0026] Described heat treatment process specifically comprises the following steps:

[0027] (1) Homogenization: put the alloy casting into a heat treatment furnace in a protective atmosphere, first heat it to 540°C at a heating rate of 30°C / min and hold it for 4 hours, then heat it to 632°C at the same heating rate and Continue to keep warm for 6 hours, and then water quench to room temperature after the end.

[0028] (2) Hot rolling: The homogenized alloy is hot-rolled for multiple passes at a temperature of 550°C, each pass is always carried out in a single direction, and the reduction of each pass is 8%, and each pass is rolled at 550°C before hot rolling Heat...

Embodiment 2

[0032] A heat treatment process for improving the strength and plasticity of cast beryllium-aluminum-scandium-zirconium alloys. The alloy components include: 64% beryllium, 35.2% aluminum, 0.4% scandium, 0.4% zirconium, and the rest are unavoidable impurities. The total mass percentage is 100%. The sum of the content is 100%.

[0033] Described heat treatment process specifically comprises:

[0034] (1) Homogenization: put the alloy casting into a heat treatment furnace in a protective atmosphere, first heat it to 520°C at a heating rate of 36°C / min and hold it for 5 hours, then heat it to 628°C at the same heating rate and Continue to keep warm for 6 hours, and then water quench to room temperature after the end.

[0035] (2) Hot rolling: The homogenized state alloy is hot-rolled for multiple passes at a temperature of 500°C. Each pass is always carried out in a single direction, and the reduction of each pass is 5%. Heat preservation for 30 minutes, the total deformation o...

Embodiment 3

[0039] A heat treatment process for improving the strength and plasticity of cast beryllium-aluminum-scandium-zirconium alloys. The alloy components include: 60% beryllium, 39% aluminum, 0.5% scandium, 0.5% zirconium, and the rest are unavoidable impurities. The total mass percentage is 100%. The sum of the content is 100%.

[0040]Described heat treatment process specifically comprises:

[0041] (1) Homogenization: Put the alloy casting into a heat treatment furnace in a protective atmosphere, first heat it to 510°C at a heating rate of 40°C / min and hold it for 6 hours, then heat it to 622°C at the same heating rate and Continue to keep warm for 8 hours, and then water quench to room temperature after the end.

[0042] (2) Hot rolling: The homogenized alloy is hot-rolled for multiple passes at a temperature of 465°C, and each pass is always carried out in a single direction, with a reduction of 8% per pass, and each pass is rolled at 465°C After heat preservation for 1 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com