Low-VOC and low-odor PC/ABS alloy material and preparation process thereof

A technology of alloy material and preparation process, which is applied in the field of low-VOC, low-odor PC/ABS alloy material and its preparation process, can solve the problems of easy oxidation of cerium and damage the stability of PC/ABS alloy material, etc., and achieve good fluidity, Improve surface finish and improve surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

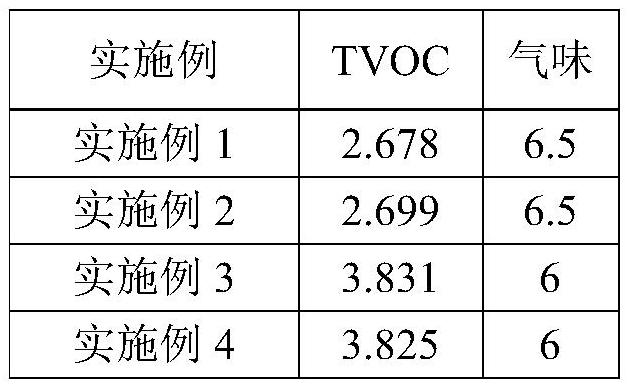

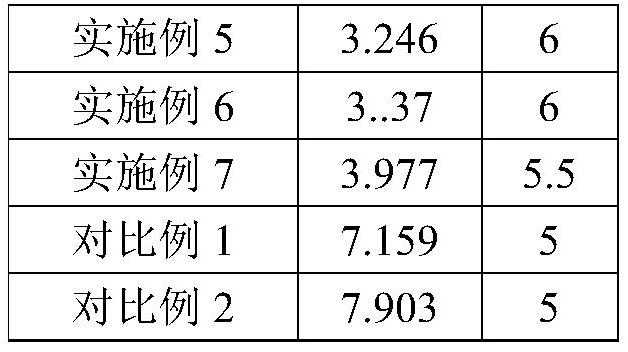

Embodiment 1

[0057] A kind of low VOC, the preparation of low odor PC / ABS alloy material is as follows:

[0058] PC / ABS alloy material, by weight: 40 parts of PC, 65 parts of ABS, 4 parts of styrene-butadiene-acrylonitrile copolymer, 0.3 part of copolymer of styrene-acrylonitrile-glycidyl methacrylate, 0.3 parts of methylenebis(6-benzotriazole-4-tertoctylphenol), 2-(2H-benzotriazol-2-yl)-4-(1,1,3,3-tetra 0.2 parts of methyl butyl) phenol, 0.2 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, tris (2,4-di-tert-butyl phenyl) 0.3 parts of phosphite, 1 part of acrylic-ethylene polymer, 3 parts of titanium dioxide, and 1 part of masterbatch.

[0059] PC / ABS alloy material preparation process: each component is added to the mixing equipment in sequence, stirred and mixed for 5 minutes, the mixture is air-dried at 100°C with hot air circulation, and the air-drying time is 4 hours. The air-dried mixture is melted and extruded in the extruder.

Embodiment 2

[0061] A kind of low VOC, the preparation of low odor PC / ABS alloy material is as follows:

[0062] PC / ABS alloy material, by weight: 65 parts of PC, 50 parts of ABS, 4 parts of styrene-butadiene-acrylonitrile copolymer, 0.4 part of copolymer of styrene-acrylonitrile-glycidyl methacrylate, 0.3 parts of methylenebis(6-benzotriazole-4-tertoctylphenol), 2-(2H-benzotriazol-2-yl)-4-(1,1,3,3-tetra 0.2 parts of methyl butyl) phenol, 0.2 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, tris (2,4-di-tert-butyl phenyl) 0.3 parts of phosphite, 1 part of acrylic-ethylene polymer, 3 parts of titanium dioxide, and 1 part of masterbatch.

[0063] PC / ABS alloy material preparation process: each component is added to the mixing equipment in sequence, stirred and mixed for 5 minutes, the mixture is air-dried at 100°C with hot air circulation, and the air-drying time is 4 hours. The air-dried mixture is melted and extruded in the extruder.

Embodiment 3

[0065] A kind of low VOC, the preparation of low odor PC / ABS alloy material is as follows:

[0066] PC / ABS alloy material, by weight: 70 parts of PC, 30 parts of ABS, 4 parts of styrene-butadiene-acrylonitrile copolymer, 0.3 part of copolymer of styrene-acrylonitrile-glycidyl methacrylate, 0.3 parts of methylenebis(6-benzotriazole-4-tertoctylphenol), 2-(2H-benzotriazol-2-yl)-4-(1,1,3,3-tetra 0.2 parts of methyl butyl) phenol, 0.2 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, tris (2,4-di-tert-butyl phenyl) 0.3 parts of phosphite, 2 parts of acrylic-ethylene polymer, 1 part of titanium dioxide, and 1 part of masterbatch.

[0067] PC / ABS alloy material preparation process: each component is added to the mixing equipment in sequence, stirred and mixed for 5 minutes, the mixture is air-dried at 100°C with hot air circulation, and the air-drying time is 4 hours. The air-dried mixture is melted and extruded in the extruder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com