Specific size ceramic microparticles using microfluidic chip, its preparation device, preparation method and application

A microfluidic chip, a specific size technology, applied in the direction of granulating raw materials, ceramic molding machines, chemical instruments and methods, etc., can solve the problems of poor microparticle shape and size adjustability, limited materials, and low production efficiency and other issues to achieve the effect of diversification of preparation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

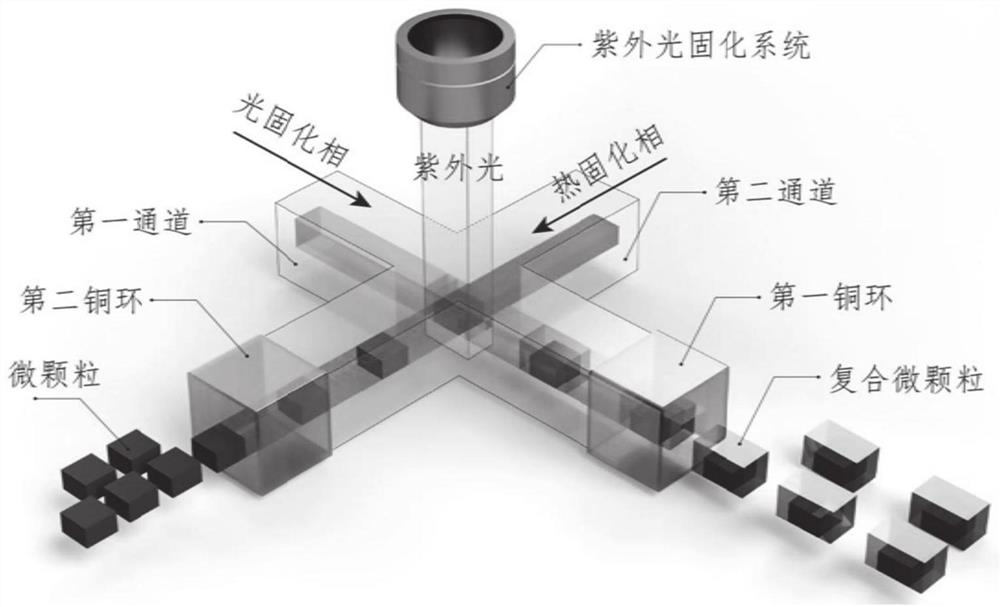

[0039] In a second aspect, the present invention provides a method for preparing ceramic microparticles of a specific size using a microfluidic chip, comprising the following steps:

[0040] Inject photocurable phase fluid into the first channel, and fill the cross forming area;

[0041] Injecting the thermosetting phase fluid into the second channel so that it keeps the cross-sectional shape of the second channel and flows through the cross forming area, and squeezes part of the light curing fluid in the cross forming area into the downstream of the second channel;

[0042] Irradiating ultraviolet light to the cross forming area, the photo-curing phase fluid undergoes a polymerization reaction and then solidifies, forming inverted "concave" micro-particles to wrap the heat-curing phase;

[0043] Continue to inject the light-cured phase fluid into the first channel, push out the light-cured particles, and repeat the above steps;

[0044] When the light-cured particles are pus...

Embodiment 1

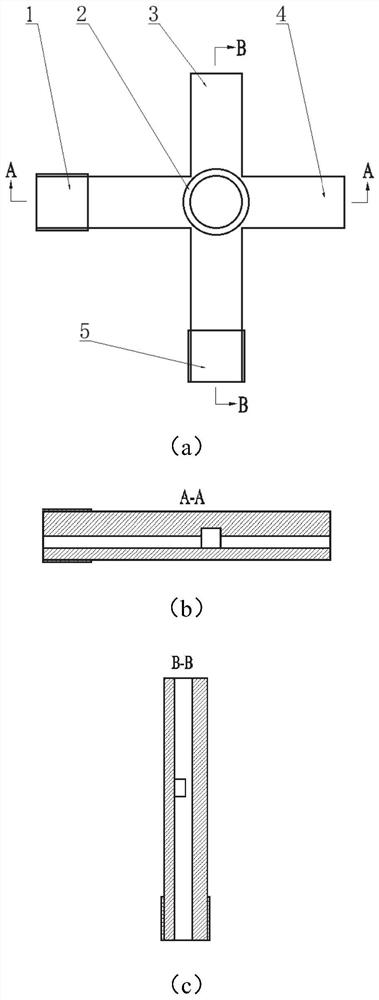

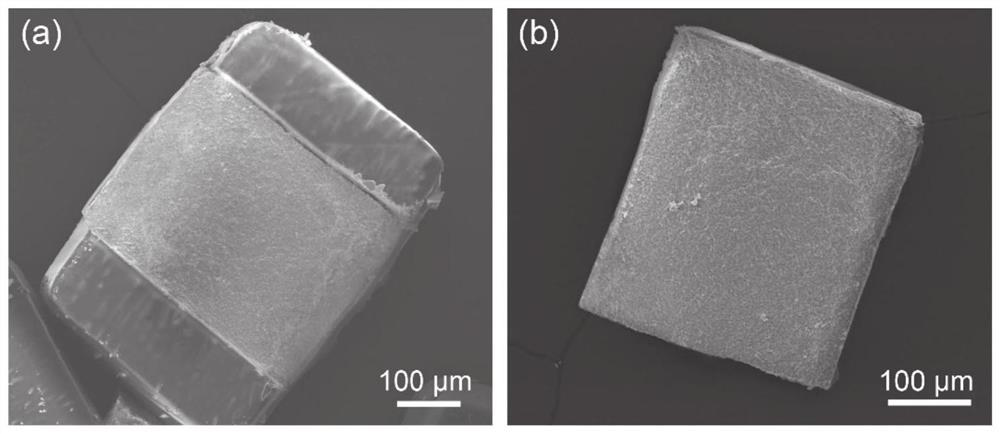

[0067] A device for preparing alumina microparticles of fixed size based on a microfluidic chip, including a microfluidic channel, a heating copper ring, and a microscope ultraviolet light system. The microfluidic channel is formed by two straight channels crossed in a cross, which are the first channel and the second channel respectively. Two channels. The height of the first channel is higher than that of the second channel. According to the flow direction of the heat-cured phase and the light-cured phase, one end of the two channels is the feeding area, the intersection part is the molding area, and the other end is the heating and curing area. A microscope ultraviolet optical path system is set above the cross molding area, and a certain shape of ultraviolet light spot is projected to this area to cure and form the thermally cured phase. In the heating and curing area, a copper ring is arranged in close contact with the heater, and the channel is heated to cure the slurry...

Embodiment 2

[0070] Preparation of alumina nano-dispersion: Weigh 17g of alumina powder, 0.17g of ammonium citrate and 5g of deionized water, mix them and mill them in a planetary ball mill at 450 rpm for 24 hours to obtain a volume ratio of alumina powder of 50% alumina dispersion.

[0071] Preparation of the thermal curing phase: Weigh 0.68g of acrylamide, 0.068g of N,N'-methylenebisacrylamide and the aluminum oxide nano-dispersion described in step 1 of this example, mix them, and vortex for 5 minutes to obtain a ceramic slurry material. Take 500 μL of ceramic slurry, add 15 mg of ammonium persulfate, and vortex for 1 minute to obtain a thermally cured phase.

[0072] Photocurable phase fluid preparation: Weigh 1 mL of ETPTA and add 40 μL of photoinitiator, shake for 2 minutes to obtain the photocurable phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com