Regeneration method of unqualified samarium-cobalt permanent magnets

A permanent magnet, samarium cobalt technology, which is applied in the manufacture of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve the problems of poor mechanical properties of samarium cobalt permanent magnets, high cost of samarium cobalt permanent magnets, and increased volatilization of samarium metal. , to improve the coercivity and mechanical properties, reduce the size of the cell structure, and increase the thickness of the cell wall phase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

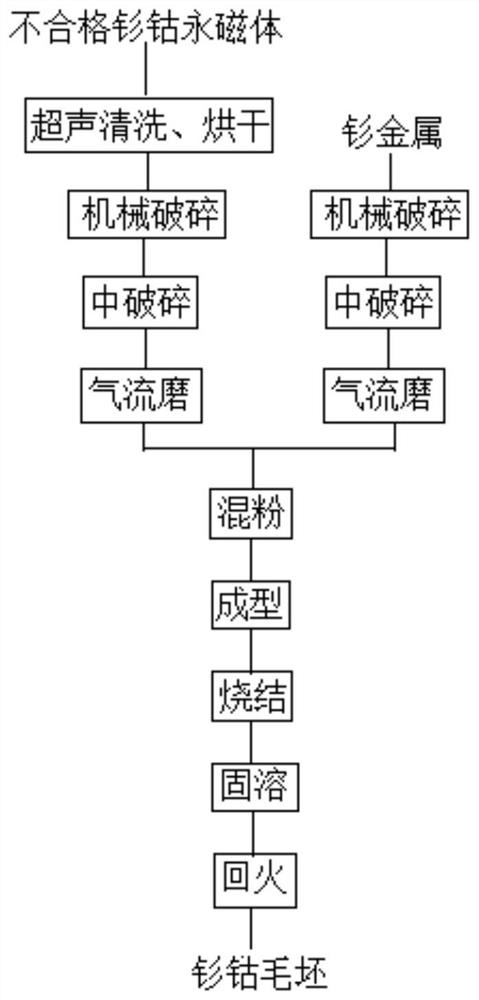

Image

Examples

Embodiment 1

[0040] (1) Ultrasonic cleaning: Use metal cleaning agent to prepare 20-40g / L cleaning solution and stir evenly. The temperature of the cleaning solution is kept at 40°C-50°C. Rub and wash for at least 2 minutes, then use a hair dryer to dry after washing with 3 levels of water;

[0041] (2) Preparation of alloy powder a: use a jaw crusher to crush the unqualified samarium-cobalt permanent magnets into coarse particles with a particle size of less than 3 mm, and use a vibrating screen to oxidize the surface of the unqualified samarium-cobalt magnets Remove the skin, then crush the above-mentioned coarse particles to obtain a powder with a particle size of less than 200 μm, add the first additive accounting for 0.015% of the powder mass to the obtained powder, use a three-dimensional powder mixer to mix the powder for 2.5 hours, and mix the powder with the first Mix the additives evenly, and then use jet milling technology to obtain alloy powder a with a particle size of 3-5 μm. D...

Embodiment 2

[0048] (1) Ultrasonic cleaning: Use metal cleaning agent to prepare 20-40g / L cleaning solution and stir evenly. The temperature of the cleaning solution is kept at 40°C-50°C. Rub and wash for at least 2 minutes, then use a hair dryer to dry after washing with 3 levels of water;

[0049] (2) Preparation of alloy powder a: use a jaw crusher to crush the unqualified samarium-cobalt permanent magnets into coarse particles with a particle size of less than 3 mm, and use a vibrating screen to oxidize the surface of the unqualified samarium-cobalt magnets Remove the skin, then crush the above-mentioned coarse particles to obtain a powder with a particle size of less than 200 μm, add the first additive accounting for 0.015% of the powder mass to the obtained powder, use a three-dimensional powder mixer to mix the powder for 2.5 hours, and mix the powder with the first Mix the additives evenly, and then use jet milling technology to obtain alloy powder a with a particle size of 3-5 μm....

Embodiment 3

[0056] (1) Ultrasonic cleaning: Use metal cleaning agent to prepare 20-40g / L cleaning solution and stir evenly. The temperature of the cleaning solution is kept at 40°C-50°C. Rub and wash for at least 2 minutes, then use a hair dryer to dry after washing with 3 levels of water;

[0057] (2) Preparation of alloy powder a: use a jaw crusher to crush the unqualified samarium-cobalt permanent magnets into coarse particles with a particle size of less than 3 mm, and use a vibrating screen to oxidize the surface of the unqualified samarium-cobalt magnets Remove the skin, then crush the above-mentioned coarse particles to obtain a powder with a particle size of less than 200 μm, add the first additive accounting for 0.015% of the powder mass to the obtained powder, use a three-dimensional powder mixer to mix the powder for 2.5 hours, and mix the powder with the first Mix the additives evenly, and then use jet milling technology to obtain alloy powder a with a particle size of 3-5 μm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com