Monorhamnolipid production strain and application thereof

A technology for the production of bacterial strains and rhamnolipids, which is applied in the direction of bacteria, microorganisms, and methods based on microorganisms, can solve the problems of high cost, complex chemical synthesis process, and restrictions on the application of ATCC9027 strains, and reduce the separation and purification process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 The construction of the genetically engineered bacterial strain that efficiently produces monorhamnolipid

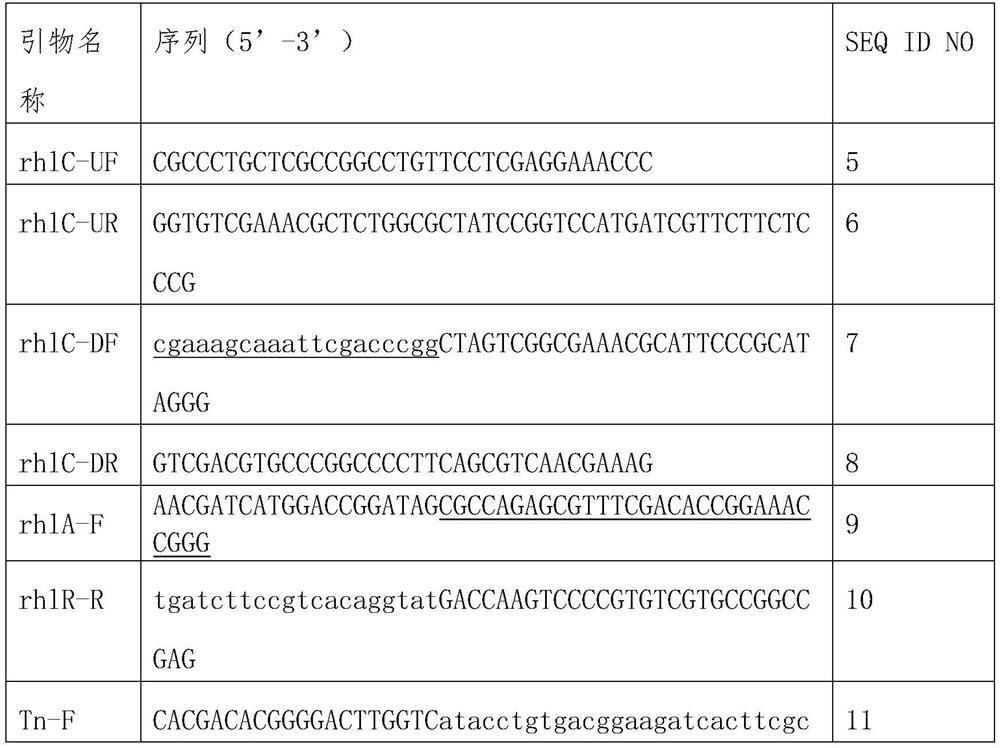

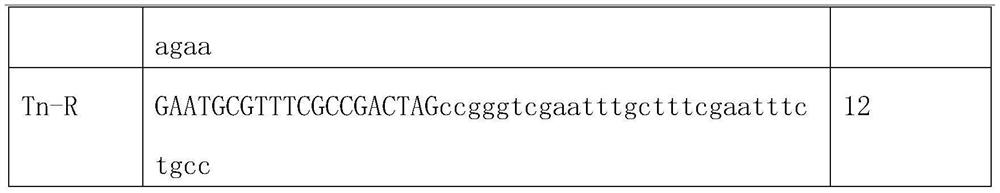

[0034] Using the genomic DNA of Pseudomonas aeruginosa PAO1 strain as a template, the primers rhlC-UF (SEQ IDNO: 5) / rhlC-UR (SEQ ID NO: 6) were used for PCR amplification respectively, and the primers rhlC-DF (SEQ ID NO: 6) were used for PCR amplification. ID NO: 7) / rhlC-DR (SEQ ID NO: 8) combined for PCR amplification, and the DNA fragment rhlC-U (SEQ ID NO: 1) upstream and downstream of the rhlC gene (KEGG accession no. PA1130) was obtained after gel cutting and recovery and rhlC-D (SEQ ID NO: 2), the length is 700bp; with the genome of Pseudomonas aeruginosa PAO1 as template, using primer rhlA-F (SEQ ID NO: 9) / rhlR-R (SEQ ID NO: 10) PCR amplification was carried out in combination and the DNA fragment rhlAB-R (SEQ ID NO: 3) including the rhlAB-R gene cluster and the promoter upstream of rhlA and the terminator sequence downstream of rhlR (SEQ ID NO...

Embodiment 2

[0038] Example 2 Fermentative production of rhamnolipid by recombinant strain P2

[0039] Fermentation verification is carried out to the genetically engineered recombinant strain P2 obtained in Example 1. First, the glycerol tube bacterium liquid that draws 100 μ L of recombinant bacterial strain P2 is inoculated into 25 mL LB (10 g / L tryptone, 5 g / L yeast powder) in a 100 mL shake flask. , 10g / L sodium chloride) liquid medium, cultured at 37°C, 120rpm for 24h. Transfer 5 mL of overnight cultured LB culture broth to 200 mL seed medium in a 1 L shake flask, and cultivate at 37 °C, 120 rpm for 24 h. The composition of the seed medium is: 125g / L sunflower oil (commercially available Arowana sunflower oil), 1.5g / L NaNO 3 ,0.05g / L MgSO4 7H 2 O, 0.1g / L KCl, 0.1M NaH 2 PO 4 -Na 2 HPO 4 Buffer, pH 6.5, 1mL / L trace element solution (2.0g / L sodium citrate dihydrate, 0.28g / L FeCl 3 ·6H 2 O,1.4g / L ZnSO 4 ·7H 2 O,1.2g / L CoCl 2 ·6H 2 O,1.2g / L CuSO 4 ·5H 2 O,0.8g / L MnSO 4 ·H ...

Embodiment 3

[0040] Example 3 Determination of concentration and purity of recombinant strain P2 fermented to produce monorhamnolipid

[0041] Centrifuge the fermentation broth at 5000rpm for 10min, take the supernatant, add concentrated hydrochloric acid to adjust the pH to 2.0, add an equal volume of chloroform / methanol (v:v=2:1) solution, vortex at high speed for 1min, extract twice, and collect The obtained organic phases were combined and volatilized in vacuo to finally obtain the rhamnolipid product, and the total rhamnolipid concentration was detected by the sulfate anthrone method. The specific measurement method is: add 100 μL rhamnolipid solution diluted with methanol to 1 mL 0.1% anthrone solution (prepared with 70% sulfuric acid), treat at 80°C for 30 min, then cool to room temperature, and detect 625nm At the same time, different concentrations of rhamnose were used to make a standard curve, and finally the concentration of the measured liquid rhamnose was obtained through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com