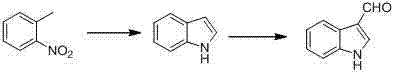

Synthetic method for indole-3-carboxaldehyde compounds

A technology of indole formaldehyde and synthesis method, applied in the direction of organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

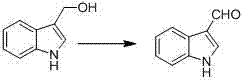

Problems solved by technology

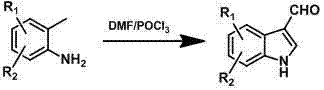

Method used

Image

Examples

Embodiment 1

[0034] Add o-methylaniline (10 g, 93 mmol) and 10 ml of DMF into the flask, and slowly add 20 ml of Vilsmeier reagent prepared dropwise at 0°C. After the dropwise addition, stir at room temperature (about 25°C) for 1 hour. Then the temperature was raised to 85° C., and the reaction was heated for 5 hours. After the completion of the detection reaction, a saturated sodium carbonate solution was added until it was alkaline, and a large amount of solids were precipitated, filtered, and dried to obtain 12.4 grams of solids, with a yield of 96%. The resulting product had a melting point of 198-199°C.

[0035] 1 H NMR (DMSO-d 6 ) 12.14 (1H, broad), 9.95 (1H, s), 8.30-8.09 (2H, m), 7.56-7.20 (3H, m); 13 C NMR (DMSO-d 6 ) 185.34, 138.85, 137.43, 124.49, 123.84, 122.50, 121.20, 118.54, 112.80.

[0036] Example 2

Embodiment 2

[0038] 4-Amino-3-methylphenol (15 g, 121.8 mmol) and 10 ml of DMF were added to the flask, and 20 ml of the prepared Vilsmeier reagent was slowly added dropwise at 0°C. After the dropwise addition was complete, stir at room temperature for 1 hour. Then the temperature was raised to 85° C., and the reaction was heated for 7 hours. After completion of the reaction, saturated sodium carbonate solution was added until it was alkaline, and a large amount of solids were precipitated. After filtration and drying, 18 grams of solids were obtained, with a yield of 92%. The resulting product had a melting point of 235°C.

[0039] 1 H NMR (DMSO-d 6 ) δ: 11.89 (1H, s), 9.84 (1H, s), 9.07 (1H, s), 8.13 (1H, s), 7.48 (1H, d), 7.29 (1H, d), 6.73 (1H, dd ).

[0040] Example 3

Embodiment 3

[0042] 2,3-Dimethyl-aniline (10 g, 82.5 mmol) and 10 ml of DMF were added to the flask, and 25 ml of the prepared Vilsmeier reagent was slowly added dropwise at 0°C. After the dropwise addition was complete, stir at room temperature for 1 hour. Then the temperature was raised to 85° C., and the reaction was heated for 7 hours. After the reaction was complete, saturated sodium carbonate solution was added until it was alkaline, and a large amount of light yellow solids were precipitated, which were filtered and dried to obtain 11.8 g of solids, with a yield of 90%. The resulting product had a melting point of 198-199°C.

[0043] 1 H NMR (DMSO-d6, 400 MHz) δ: 12.51(1H, broad), 9.97 (1H, s), 7.34 (1H, d), 7.20 (1H, d), 6.98 (1H, d), 6.73 (1H , d), 2.35 (3H, s).

[0044] Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com