Phospholipid-based emulsifier for emulsion explosive and preparation method thereof

A technology of emulsified explosives and emulsifiers, which is applied in the direction of non-explosive/non-thermal agent components, explosives, offensive equipment, etc. It can solve the problems of complex synthesis process, blasting performance, unreachable storage stability, and high price, and achieve synthetic The effect of simple process, low cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Place 500.0 g of concentrated soybean lecithin in a reactor with a heating device, slowly heat up to 50°C and start stirring under a vacuum of 0.09MPa, and add 12.5g of maleic anhydride; continue to heat up to 95°C, the reaction time 3.0h, stop the reaction when the acylation rate is ≥87%. According to the quality of the acylated modified phospholipid generated, 40 grams of the grafting reagent triethanolamine was added dropwise, reacted for 12.0 h at a reaction temperature of 100 ° C, and the acid value of the reactant was determined to be ≤ 27.5 mg KOH / g to obtain the product phospholipid-based emulsifier a.

Embodiment 2

[0039] Put 1000.0 g of concentrated soybean lecithin in a reactor with a heating device, slowly raise the temperature to 65°C and start stirring under the condition of vacuum degree of 0.095MPa, and add 60.0g of maleic anhydride; continue to heat up to 85°C, and react for 4.0h, Stop the reaction when the acylation rate is ≥91%. According to the quality of the acylated modified phospholipid generated, 30.0 g of the grafting reagent diethanolamine was added dropwise, reacted for 8.0 h at a reaction temperature of 90 ° C, and the acid value of the reactant was determined to be ≤ 29.2 mg KOH / g to obtain the product phospholipid-based emulsifier b.

Embodiment 3

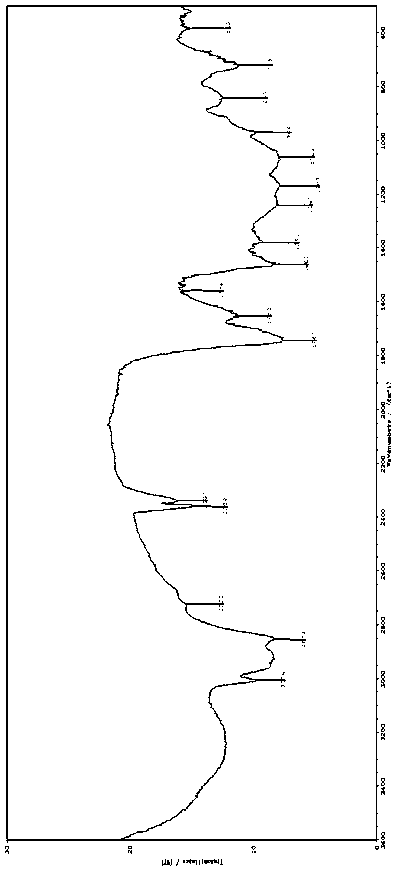

[0041] Put 500.0 g of concentrated soybean lecithin in a reactor with a heating device, and slowly raise the temperature to 50°C to start stirring under a vacuum of 0.090MPa, and add 25.0g of acetic anhydride; continue to heat up to 90°C, and react for 2.5h , Stop the reaction when the acylation rate is ≥90%. According to the quality of the acylated modified phospholipid generated, 32.5 grams of grafting reagent diethanolamine was added dropwise, reacted for 8.0 h at a reaction temperature of 95 ° C, and the acid value of the reactant was determined to be ≤ 26.2 mg KOH / g to obtain the product phospholipid-based emulsifier C, its infrared spectrum is shown in figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com