Degradable nano-hydroxyapatite magnesium-based composite material and preparation method thereof

A technology of hydroxyapatite and hydroxyapatite powder, which is applied in the fields of pharmaceutical formula, medical science, prosthesis, etc., to improve the living environment of cells, increase the degree of alloying and strength, and inhibit corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Raw material preparation: select high-purity magnesium powder with a particle size of about 60 μm (purity ≥ 99.9%), high-purity zinc powder with a particle size of about 10 μm (purity ≥ 99.9%), and analyze pure nano-hydroxyphosphorus with a particle size of ≤ 60 nm Ash stone powder (HA). Weigh and prepare separately according to the weight ratio of 91:4:5.

[0026] (2) Powder mixing: Mix the weighed powders together and pour them into a star-shaped powder mixer. Because the chemical properties of magnesium powder are active, it is easy to cause danger if the powder mixer turns too fast, and it is difficult to achieve a uniform mixing if it is too slow. Therefore, set the speed of the mixer to 20r / min and the mixing time to 80 hours. When the time is up, turn off the powder mixer, take out the raw material powder mixed in proportion and pack it into bags.

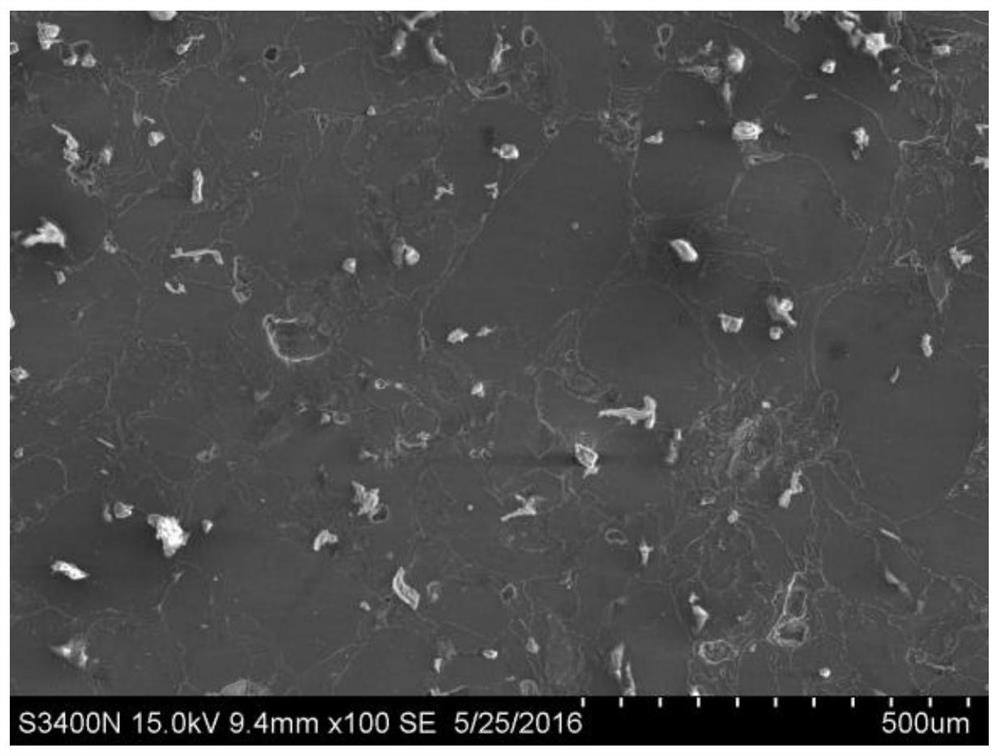

[0027] (3) Cold extrusion: Pour the wrapped powder into the cold extrusion mold, install the mold, apply pres...

Embodiment 2

[0031] (1) Raw material preparation: select high-purity magnesium powder with a particle size of about 60 μm (purity ≥ 99.9%), high-purity zinc powder with a particle size of about 10 μm (purity ≥ 99.9%), and analyze pure nano-hydroxyphosphorus with a particle size of ≤ 60 nm Ash stone powder (HA). Weigh and prepare separately according to the weight ratio of 86:4:10.

[0032] (2) Perform powder mixing, cold pressing, and sintering according to the steps (2)-(4) in Example 1.

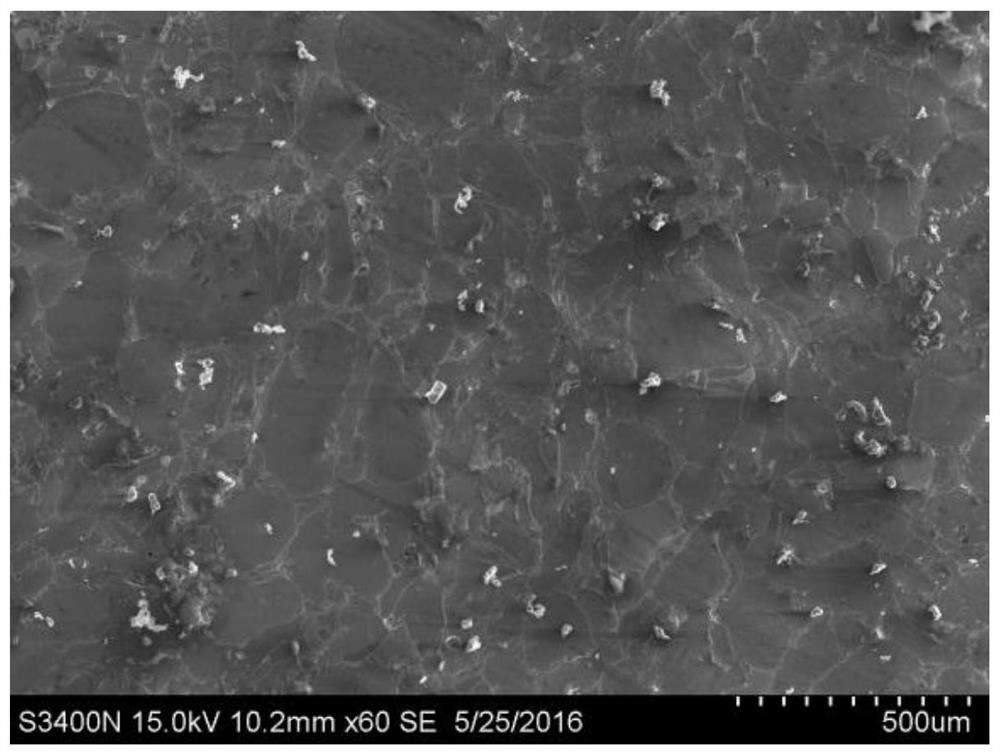

[0033] (3) The Mg-Zn / 10HA composite material was prepared according to the above procedures, and its microstructure was attached figure 2 As shown, the alloying degree of magnesium powder and zinc powder is good, and the XRD test forms MgZn2 phase, HA powder evenly fills the alloy pores, does not react with the alloy powder after sintering, maintains its biological activity, and is still uniformly distributed at the grain boundary of the matrix. Alloy hardness is 56HRB. The results of electrochemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com