Bulk phase hydrogenation catalyst and preparation method thereof

A technology of catalyst and auxiliary agent, applied in the field of oil hydrogenation, can solve the problems of difficult vulcanization, reduction of catalyst active metal sulfidation degree, and reduction of quantity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

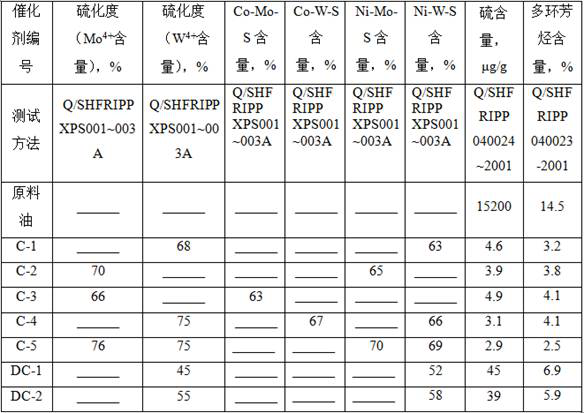

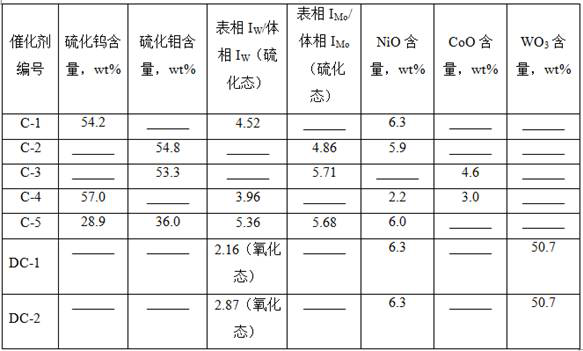

Examples

Embodiment 1

[0028] Dissolve ammonium metatungstate and aluminum chloride in deionized water to prepare mixed solution A. In mixed solution A, WO 3 The weight concentration is 80g / L, Al 2 o 3 The weight concentration is 50g / L. Slowly add sodium hydroxide with a concentration of 1.0mol / L into 1L of solution A under stirring, keep the gelling temperature at 70°C, control the pH value at 7~8 at the end, control the gelling time at 60 minutes, and form Slurry I containing tungsten and aluminum precipitates.

[0029] Mix 160 mL of 1.0 mol / L magnesium nitrate solution with slurry I evenly, then adjust the pH value to 7~8 with ammonia water, wash with deionized water three times, filter and dry at 120°C for 5 hours to obtain a mixed powder. Then take 150g of mixed powder and mix with 5g of nitric acid, 5g of starch and 60g of deionized water evenly, then knead and extrude, dry at 120°C for 3h, and roast at 500°C for 3h, and then use 1.5%H 2 The hydrogen of S is vulcanized, the vulcanization t...

Embodiment 2

[0032] Dissolve ammonium metamolybdate and aluminum sulfate in deionized water to prepare mixed solution A, and MoO in mixed solution A 3 The weight concentration is 80g / L, Al 2 o 3 The weight concentration is 50g / L. Slowly add sodium hydroxide with a concentration of 1.0mol / L into 1L of solution A under stirring, keep the gelling temperature at 80°C, control the pH value at 7~8 at the end, control the gelling time at 90 minutes, and form Molybdenum and aluminum precipitate slurry I.

[0033] Mix 100mL of 1.0mol / L zirconium nitrate solution with slurry I evenly, then adjust the pH value to 7~8 with ammonia water, then wash with deionized water three times, filter and dry at 110°C for 6 hours to obtain a mixed powder. Then take 150g of mixed powder and mix with 10g of phosphoric acid, 5g of starch and 60g of deionized water evenly, then knead and extrude, dry at 120°C for 3h, and bake at 600°C for 2h, and then use 1.5%H 2 The hydrogen of S is vulcanized, the vulcanization t...

Embodiment 3

[0036] Dissolve ammonium metamolybdate and aluminum sulfate in deionized water to prepare mixed solution A, and MoO in mixed solution A 3 The weight concentration is 80g / L, Al 2 o 3 The weight concentration is 50g / L. Slowly add sodium hydroxide with a concentration of 1.0mol / L into 1L of solution A under stirring, keep the gelling temperature at 80°C, control the pH value at 7~8 at the end, control the gelling time at 90 minutes, and form Molybdenum and aluminum precipitate slurry I.

[0037] Mix 160mL of 1.0mol / L zirconium nitrate solution with slurry I evenly, then adjust the pH value to 7~8 with ammonia water, then wash with deionized water three times, filter and dry at 110°C for 6 hours to obtain a mixed powder. Then take 150g of mixed powder and mix with 10g of phosphoric acid, 5g of starch and 60g of deionized water evenly, then knead and extrude, dry at 120°C for 3h, and bake at 600°C for 2h. Then use 3wt%CS 2 The jet fuel is vulcanized at an air speed of 1.0h -1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com