Perovskite double-band photoelectric detector and preparation method thereof

A technology of perovskite and perovskite precursors, applied in photovoltaic power generation, electric solid-state devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of cumbersome follow-up processing procedures, small film grain size, and poor film quality. Achieve high wavelength selectivity, large grain size, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

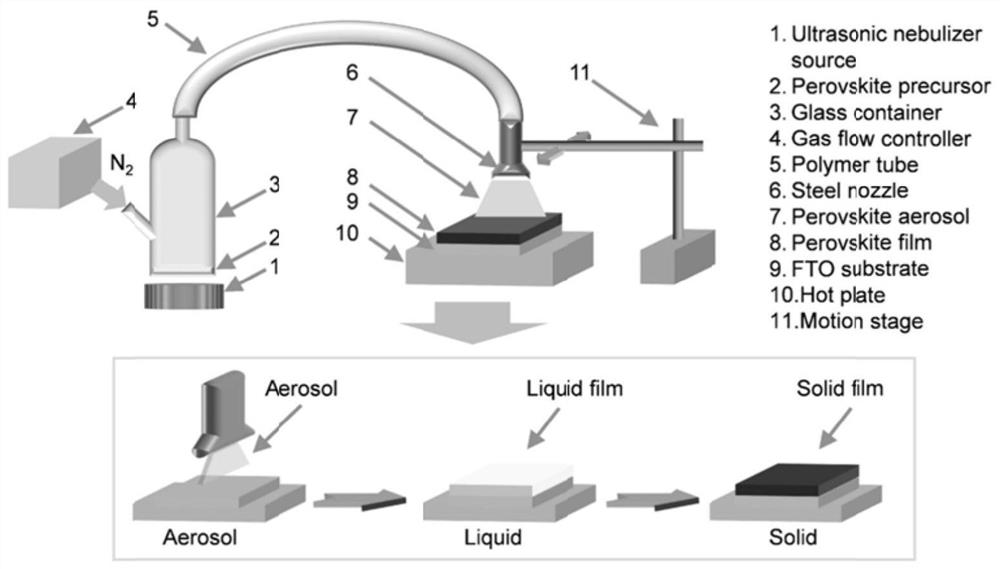

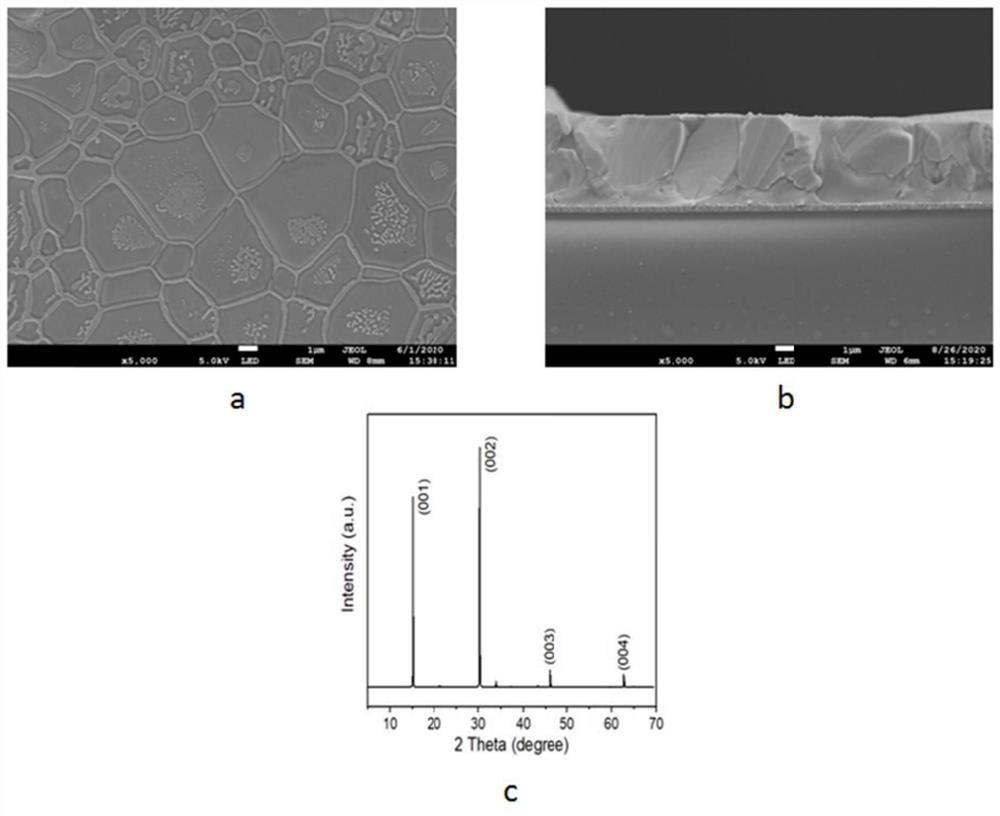

[0054] A kind of perovskite dual-band photodetector, its preparation method comprises the steps:

[0055] (1) Use deionized water, acetone, isopropanol and ethanol to ultrasonically clean the FTO transparent conductive substrate in sequence, and then put it in an oven for 70 o C is dry and ready for use;

[0056] (2) Dissolve 10mmol lead bromide and 10mmol methylamine hydrobromide powder in 12.5ml DMSO and DMF mixed solvent (the volume ratio of DMSO and DMF is 1:1), stir well to obtain MAPbBr 3 The precursor solution (molar concentration is 0.8mol / L); the MAPbBr 3 The precursor solution is atomized to form atomized MAPbBr 3 Precursor solution;

[0057] (3) Place the transparent conductive substrate on the heating table, and the temperature of the heating table rises to 130 o C, the distance between the nozzle and the upper surface of the conductive substrate is adjusted to 3 mm, and the moving speed of the nozzle is controlled to 0.6 cm / s. Use dry nitrogen to pass into th...

Embodiment 2

[0060] A kind of perovskite dual-band photodetector, its preparation method comprises the steps:

[0061] (1) Use deionized water, acetone, isopropanol and ethanol to ultrasonically clean the FTO transparent conductive substrate, and then put it in an oven for 80 o C is dry and ready for use;

[0062] (2) Dissolve 5mmol lead bromide, 5mmol lead chloride, 5mmol methylamine hydrobromide and 5mmol methylamine hydrochloride powder in 12.5ml DMSO and DMF mixed solvent (the volume ratio of DMSO and DMF is 1:1 ), and stir evenly to obtain MAPbBr 1.5 Cl 1.5 The precursor solution (molar concentration is 0.8mol / L); the MAPbBr 1.5 Cl 1.5 The precursor solution is atomized to form atomized MAPbBr 1.5 Cl 1.5 Precursor solution;

[0063] (3) Place the transparent conductive substrate on the heating table, and the temperature of the heating table rises to 140 o C, the distance between the nozzle and the upper surface of the conductive substrate is adjusted to 5 mm, and the moving sp...

Embodiment 3

[0066] A kind of perovskite dual-band photodetector, its preparation method comprises the steps:

[0067] (1) Use deionized water, acetone, isopropanol and ethanol to ultrasonically clean the FTO transparent conductive substrate, and then put it in an oven for 90 o C is dry and ready for use;

[0068] (2) Dissolve 10mmol lead bromide, 9mmol methylamine hydrobromide and 1mmol methylamine hydrobromide powder in 12.5ml DMSO and DMF mixed solvent (the volume ratio of DMSO and DMF is 1:1), and stir evenly to obtain FA 0.1 MA 0.9 PbBr 3 The precursor solution (molar concentration is 0.8mol / L); the FA 0.1 MA 0.9 PbBr 3 The precursor solution is atomized to form atomized FA 0.1 MA 0.9 PbBr 3 Precursor solution;

[0069] (3) Place the transparent conductive substrate on the heating table, and the temperature of the heating table rises to 150 o C, the distance between the nozzle and the upper surface of the conductive substrate is adjusted to 7mm, and the moving speed of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com