Artificial joint with durable lubricating surface layer and preparation method of artificial joint

An artificial joint and surface technology, applied in metal material coating technology, coating, medical science and other directions, can solve problems such as shedding and lubrication failure, and achieve the effect of preventing direct contact, good wear resistance, and good boundary lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The following is the preparation method for artificial joints prepared by using titanium alloy substrates. The overall steps are as follows

[0044] (1) carrying out hydroxylation treatment on the titanium alloy substrate to form a hydroxylated substrate;

[0045] (2) Soak the hydroxylated substrate in a silane coupling agent solution to form a silane layer;

[0046] (3) The titanium alloy substrate with the silane layer on the surface is coated with a photoinitiator benzophenone, added to the electrolyte monomer solution to be grafted, and irradiated by an ultraviolet lamp to form a polyelectrolyte brush layer;

[0047] (4) Immersing the titanium alloy substrate grafted with polyelectrolyte brushes on the surface into the first polyion electrolyte solution to form a single cross-linked polyelectrolyte brush layer;

[0048] (5) then put into the second polyion electrolyte solution to form a double cross-linked polyelectrolyte brush layer;

[0049] (6) Repeat steps (4)...

Embodiment 1

[0067] Preparation of 1# titanium alloy artificial joint with durable lubricating surface.

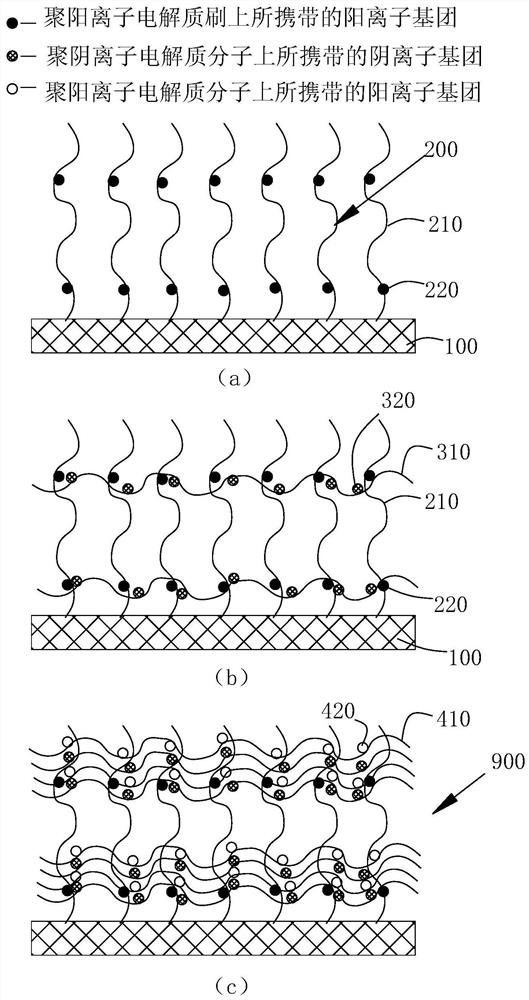

[0068] see figure 1 , subjecting the titanium alloy substrate to oxygen plasma treatment for 5 minutes to obtain a hydroxylated substrate; immersing the hydroxylated titanium alloy in a methacryloxypropyltriethoxysilane solution with a mass fraction of 1% for 1 hour; Coat the surface of the silanized titanium alloy with benzophenone at a concentration of 0.5 mg / mL, and then add it to the cationic monomer methacryloyloxyethyltrimethylammonium chloride solution to be grafted at a concentration of 0.05 mol / L, irradiated by UV lamp for 5min, please refer to figure 1 In the (a) step, the grafted polycation electrolyte brush layer 200 is formed, wherein the mark 210 represents the polyelectrolyte molecule in the graft polycation electrolyte brush layer 200, and the mark 220 represents the cationic group carried on the polyelectrolyte molecule 210 group.

[0069] The titanium alloy substra...

Embodiment 2

[0076] Preparation of 2# titanium alloy artificial joint with durable lubricating surface.

[0077] The titanium alloy substrate was irradiated with ultraviolet light for 20 minutes to obtain a hydroxylated substrate; the hydroxylated titanium alloy was immersed in a methacryloxypropyltriethoxysilane solution with a mass fraction of 3%, and the time 5h; Coat the surface of the silanized titanium alloy with benzophenone at a concentration of 1mg / mL, and then add it to the cationic monomer methacryloylpropyltrimethylammonium chloride solution to be grafted at a concentration of 1mol / L, irradiated with ultraviolet light for 10min to form a grafted polycation electrolyte brush layer; the titanium alloy substrate grafted with polycation electrolyte brushes on the surface was immersed in a sodium polystyrene sulfonate anion electrolyte solution with a concentration of 0.5mg / mL Take it out and wash it with deionized water; then dip it into the chitosan polycation electrolyte solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com