In-situ cross-linked polymer binding agent for lithium ion battery and electrode prepared from same

A lithium-ion battery, in-situ cross-linking technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of irreversible slippage between active material particles and polymer binders, irreversible capacity increase, etc. , to achieve the effect of non-toxic and non-polluting source, conducive to dispersion uniformity and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

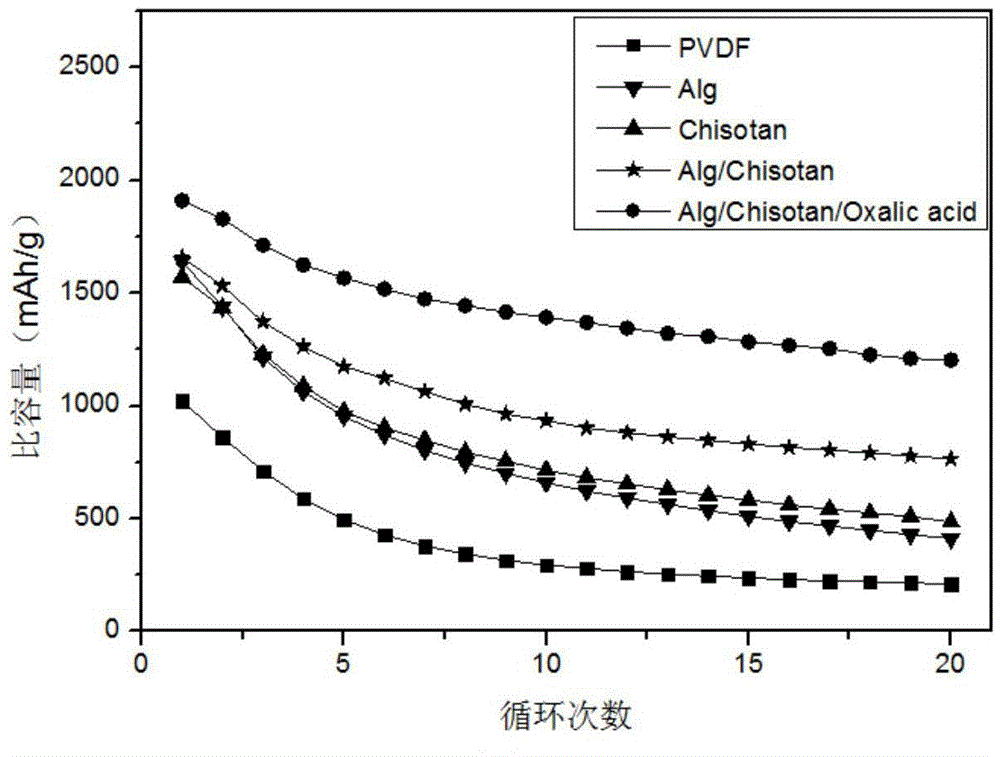

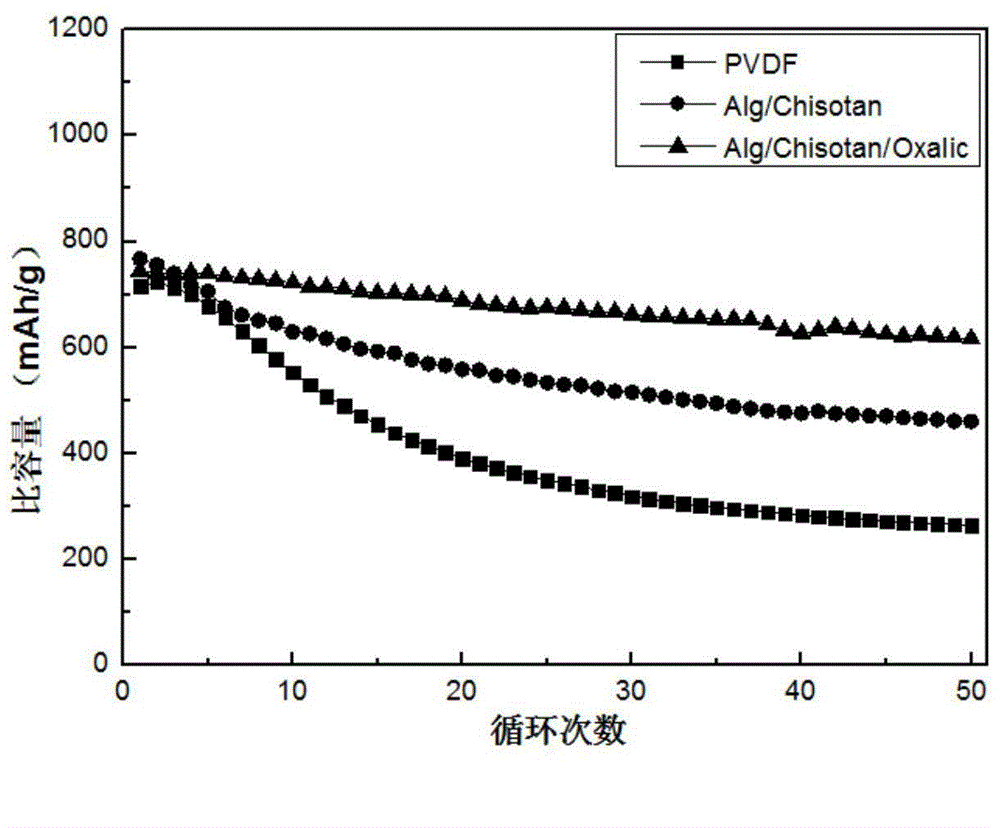

Embodiment 1

[0033] Sodium alginate (Alg) with a medium viscosity, a molecular weight of 800,000-1,200,000 g / mol, and a monomer ratio of glucuronic acid (M) to guluronic acid (G) of about 1.56 is prepared into a 2% aqueous solution ; The water-soluble chitosan (Chisotan) with a carboxylation degree greater than or equal to 60% is formulated into a 5% aqueous solution. Take 1.2g of spherical silicon particles with a particle size distribution of 50-150nm and 0.5g of conductive carbon black (Super-P) into 6.5g of sodium alginate aqueous solution and mix well, add 3g of chitosan solution, and then add 0.03g Oxalic acid powder, and add 6.5g of pure water, adjust the solid content of the slurry to 11.6% and mix evenly. The obtained slurry is uniformly coated on the copper current collector, and the loading amount of the active silicon material is controlled at 1.5 mg / cm 2 ; After air-drying at room temperature, roll it with a roller machine, and control the compaction density to 0.7mg / cm 3 . ...

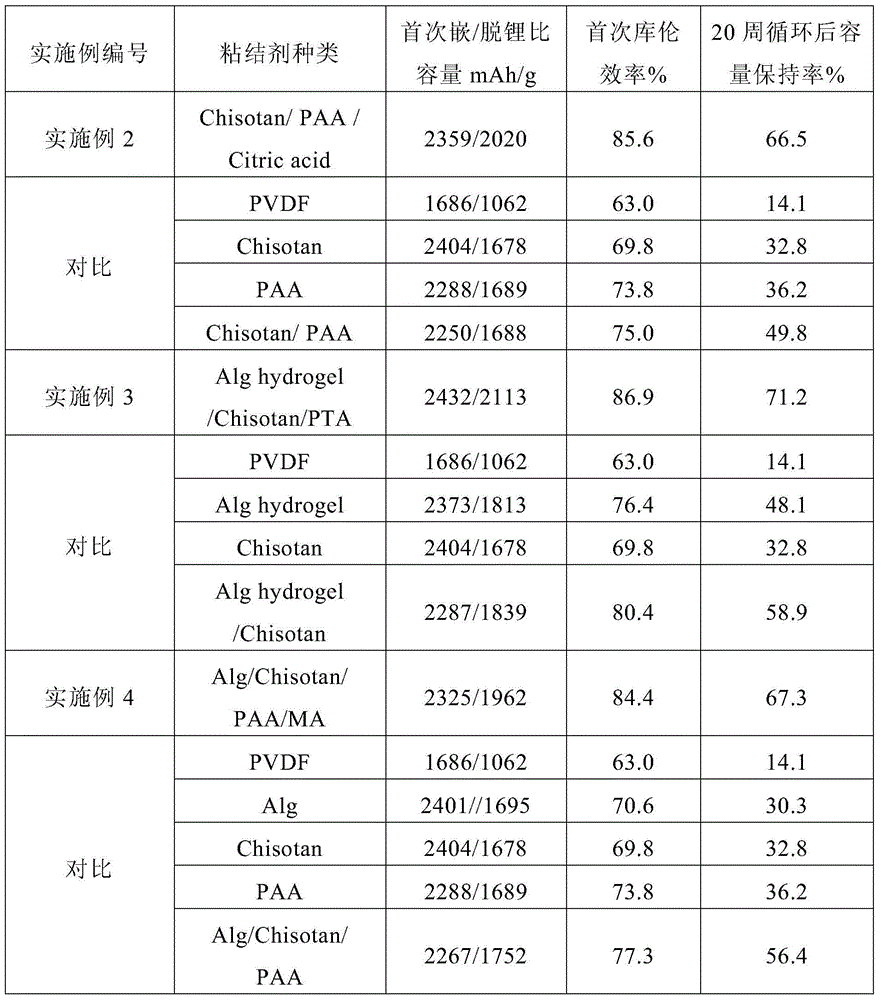

Embodiment 2

[0039] The polyacrylic acid with a molecular weight of 100000g / mol is prepared into a 5% aqueous solution; the water-soluble chitosan with a carboxylation degree greater than or equal to 60% is prepared into a 5% aqueous solution. Get 1.2g of spherical silicon particles with a particle size distribution of 50-150nm and 0.5g of conductive carbon black (Super-P) into a mixed solution of 3g of water-soluble chitosan and 2.4g of polyacrylic acid, then add 0.0328g of lemon monohydrate acid, and add 10g of pure water to adjust the solid content of the slurry to 11.6% and mix well. The obtained slurry is uniformly coated on the copper current collector, and the loading amount of the active silicon material is controlled at 1.5 mg / cm 2 ; After air-drying at room temperature, roll it with a roller machine, and control the compaction density to 0.7mg / cm 3 . The obtained electrode ratio is: active silicon material:conductive additive:polymer binder=60:25:15. Wherein the mass fraction ...

Embodiment 3

[0044] Take 2g of sodium alginate powder with a medium viscosity, a molecular weight of 800,000-1,200,000g / mol, and a monomer ratio of glucuronic acid (M) to guluronic acid (G) of about 1.56, and add it to 98g of pure water Prepare 2% aqueous solution, add 0.02g anhydrous CaCl 2 Formulated into sodium alginate hydrogel (Alg hydrogel). The water-soluble chitosan whose carboxylation degree is greater than or equal to 60% is formulated into a 5% aqueous solution. Take 1.2g of spherical silicon particles with a particle size distribution of 50-150nm and 0.5g of conductive carbon black (Super-P) into a mixed solution of 7.0g of sodium alginate hydrogel and 3g of chitosan, and then add 0.01g of Phthalic acid powder, and 5.5g of pure water was added to adjust the solid content of the slurry to 11.6% and mixed evenly. The obtained slurry is uniformly coated on the copper current collector, and the loading amount of the active silicon material is controlled at 1.5 mg / cm 2 ; After ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com