Special material for transparent nylon tube and preparation method thereof

A nylon tube and special material technology, which is applied in the field of special materials for transparent nylon tubes and its preparation, can solve the problems of large temperature influence, poor resistance to bending deformation, poor flexibility, etc., and achieves excellent low temperature resistance, good wear resistance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

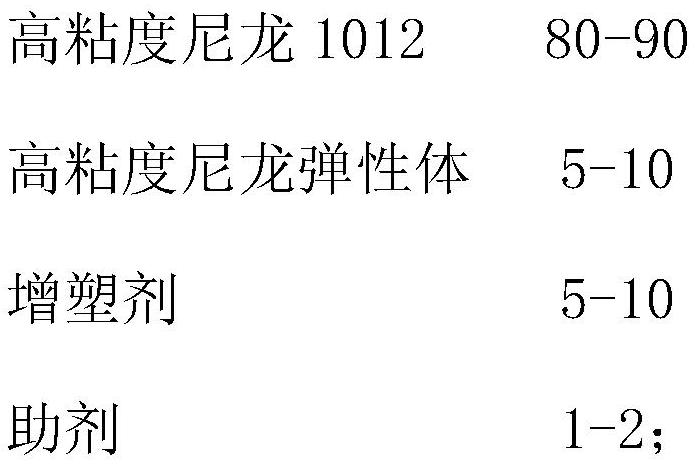

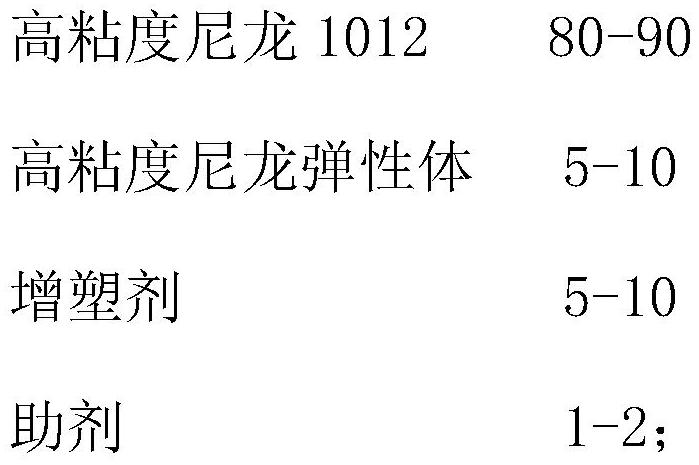

Method used

Image

Examples

Embodiment 1

[0026] A kind of preparation method of nylon tube special material, wherein, comprises the following steps:

[0027] (1) Preparation of high-viscosity nylon 1012: Add decanediamine, dodecanedibasic acid, sebacic acid and distilled water into the kettle at a mass ratio of 2.5:3:1, raise the temperature and pressure to 240°C, discharge water vapor, The pressure reaches 1.5MPa, after 2 hours of reaction, it is lowered to normal pressure, the temperature is controlled at 250°C, pressurized, extruded, cooled, pelletized, dried, and packaged to obtain transparent copolymerized nylon 1012;

[0028] Add 100Kg of copolymerized nylon 1012 into a conical vacuum rotary dryer, raise the temperature to 165°C and react at a negative pressure of -0.098MPa for 8 hours, detect the melt index and control it at 4-6g / 10min to obtain high-viscosity nylon 1012;

[0029] (2) Preparation of high-viscosity nylon elastomer: Add decanediamine, dodecanedibasic acid and alcohol into the neutralization kett...

Embodiment 2

[0035] A kind of preparation method of nylon tube special material, wherein, comprises the following steps:

[0036] (1) Preparation of high-viscosity nylon 1012: Add decanediamine, dodecanedibasic acid, sebacic acid and distilled water into the kettle at a mass ratio of 2.5:3:1, raise the temperature and pressure to 240°C, discharge water vapor, The pressure reaches 1.5MPa, after 3 hours of reaction, it is lowered to normal pressure, the temperature is controlled at 250°C, pressurized, extruded, cooled, pelletized, dried, and packaged to obtain transparent copolymerized nylon 1012;

[0037] Add 100Kg of copolymerized nylon 1012 into a conical vacuum rotary dryer, raise the temperature to 165°C and react at a negative pressure of -0.098MPa for 8 hours, detect the melt index and control it at 4-6g / 10min to obtain high-viscosity nylon 1012;

[0038] (2) Preparation of high-viscosity nylon elastomer: Add decanediamine, dodecanedibasic acid and alcohol into the neutralization kettle...

Embodiment 3

[0043] A kind of preparation method of nylon tube special material, wherein, comprises the following steps:

[0044] (1) Preparation of high-viscosity nylon 1012: Add decanediamine, dodecanedibasic acid, sebacic acid and distilled water into the kettle at a mass ratio of 2.5:3:1, raise the temperature and pressure to 240°C, discharge water vapor, The pressure reaches 1.5MPa, after 3 hours of reaction, it is lowered to normal pressure, the temperature is controlled at 250°C, pressurized, extruded, cooled, pelletized, dried, and packaged to obtain transparent copolymerized nylon 1012;

[0045] Add 100Kg of copolymerized nylon 1012 into a conical vacuum rotary dryer, raise the temperature to 165°C and react at a negative pressure of -0.098MPa for 8 hours, detect the melt index and control it at 4-6g / 10min to obtain high-viscosity nylon 1012;

[0046] (2) Preparation of high-viscosity nylon elastomer: Add decanediamine, dodecanedibasic acid and alcohol into the neutralization kett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com