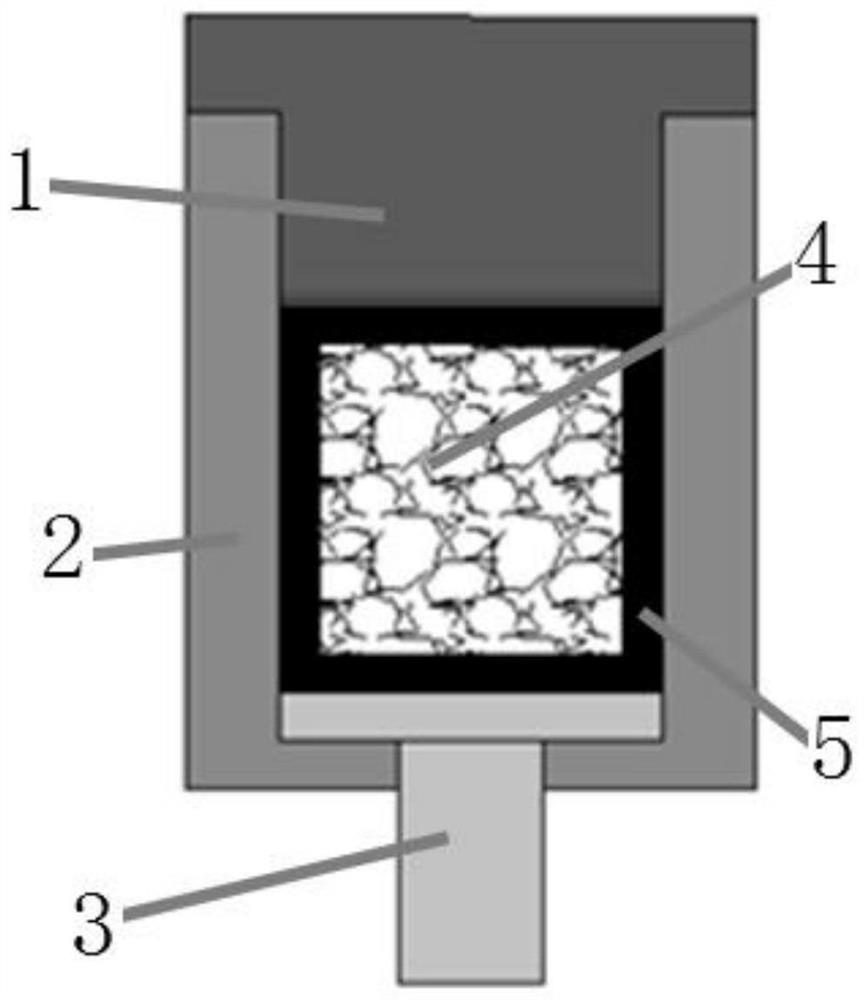

Array type ceramic preform sintering unit monomer and high-flux pressureless sintering method

A prefabricated body and array-type technology, which is applied in the field of wear-resistant material preparation, can solve the problems of ceramic prefabricated body easy to collapse, low temperature strength of prefabricated body, and poor applicability, so as to achieve high-throughput pressureless sintering and improve interface bonding strength , The effect of saving the R & D cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1) Soak ZTA ceramic particles in absolute alcohol and ultrasonically clean them for 20 minutes, and then dry them in a vacuum oven at 100°C; the selected ZTA ceramic particles range in size from 300 μm to 3 mm, with 200 μm as the interval, and 6 groups can be set Sample; Al in selected ZTA ceramic particles 2 o 3 The contents are respectively 20wt.%, 25wt.%, 30wt.%, 70wt.%, 75wt.%, 80wt.%, and 6 groups of samples can be set.

[0053] 2) Surface modification of ZTA ceramic particles was performed by a multi-arc ion coating apparatus, and three Ni 3 For Ti intermetallic compound target and α-Ti elemental target, the plating time is 3h.

[0054] 3) Combine the plated ZTA ceramic particles with Ni 3 Mix Ti powder and Ti powder evenly, the Ni used 3 Ti powder accounts for 12% of the mass fraction of ZTA ceramic particles; Ti powder accounts for 2% of the mass fraction of ZTA ceramic particles.

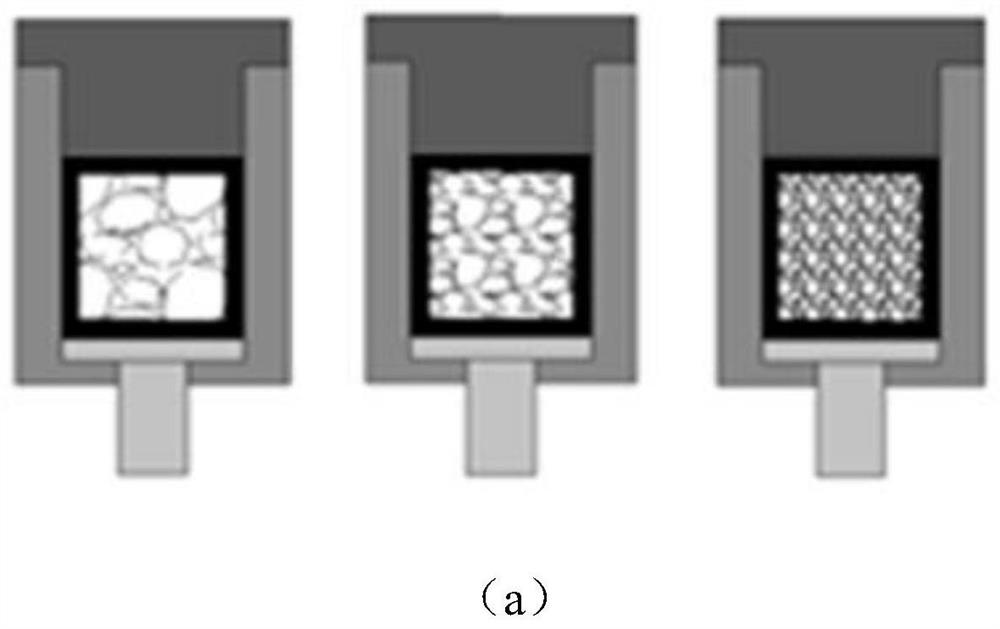

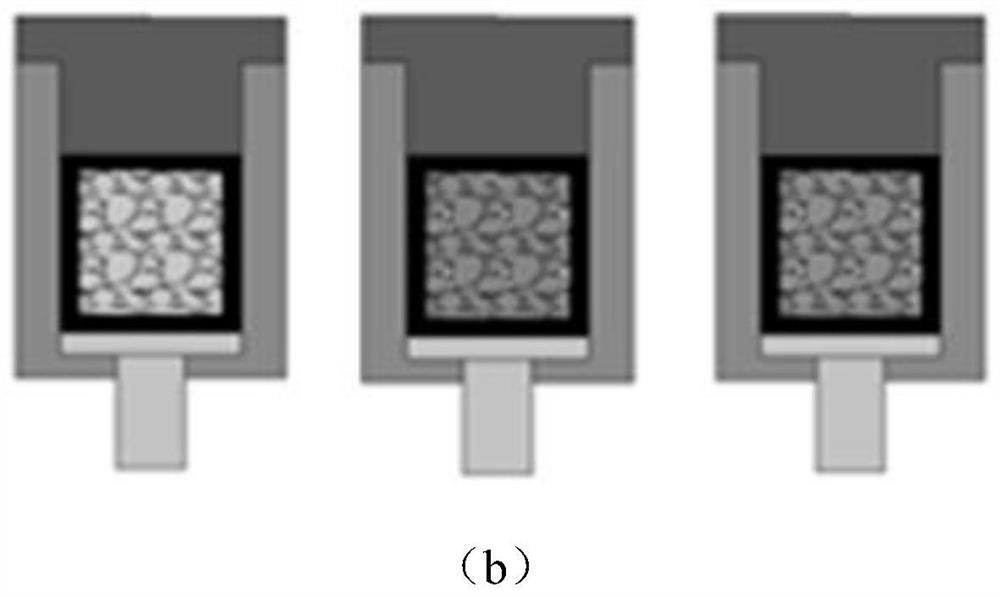

[0055] 4) Will figure 2 The shown ZTA ceramic particles + mixed powder ar...

Embodiment 2

[0060] 1) Soak the ZTA ceramic particles in absolute alcohol and ultrasonically clean them for 20 minutes, and then dry them in a vacuum oven at 100°C; the selected ZTA ceramic particles range in size from 1 mm to 2 mm; 2 o 3 The contents are respectively 20wt.%, 25wt.%, 30wt.%, 70wt.%, 75wt.%, 80wt.%, and 6 groups of samples can be set.

[0061] 2) Surface modification of ZTA ceramic particles was performed by a multi-arc ion coating apparatus, and three Ni 3 Ti intermetallic compound target and an α-Ti elemental target, the plating time is 2h;

[0062] 3) Mix the plated ZTA ceramic particles with Ni3Ti powder and Ti powder evenly, the Ni 3 Ti powder accounts for 10% of the mass fraction of ZTA ceramic particles; Ti powder accounts for 2% of the mass fraction of ZTA ceramic particles;

[0063] 4) Place ZTA ceramic particles + mixed powder together in figure 1 In the sintered unit of the ceramic preform shown, 3 parallel samples are set in each group;

[0064] 5) Place th...

Embodiment 3

[0068] 1) Soak the ZTA ceramic particles in absolute alcohol and ultrasonically clean them for 20 minutes, and then dry them in a vacuum oven at 100°C; the selected ZTA ceramic particles range in size from 300 μm to 1 mm; 2 o 3 The content is 80wt.%.

[0069] 2) Surface modification of ZTA ceramic particles was performed by a multi-arc ion coating apparatus, and three Ni 3 Ti intermetallic compound target and an α-Ti elemental target, the plating time is 2h;

[0070] 3) Combine the plated ZTA ceramic particles with Ni 3 Mix Ti powder and Ti powder evenly, the Ni used 3 Ti powder accounts for 14% of the mass fraction of ZTA ceramic particles; Ti powder accounts for 4% of the mass fraction of ZTA ceramic particles;

[0071] 4) Place ZTA ceramic particles + mixed powder together in figure 1 In the sintered unit of the ceramic preform shown, 3 parallel samples are set in each group;

[0072] 5) Place the sintered unit of the ceramic preform on the figure 2 The alumina tray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

| Scale | aaaaa | aaaaa |

| Scale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com