Low-temperature high-efficiency denitration agent and preparation method thereof

A denitrification agent and high-efficiency technology, applied in separation methods, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as large influence of low-temperature denitrification technology working conditions, human health and environmental hazards, and complex catalyst preparation processes , to avoid ammonia consumption and escape problems, less influence of working conditions and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

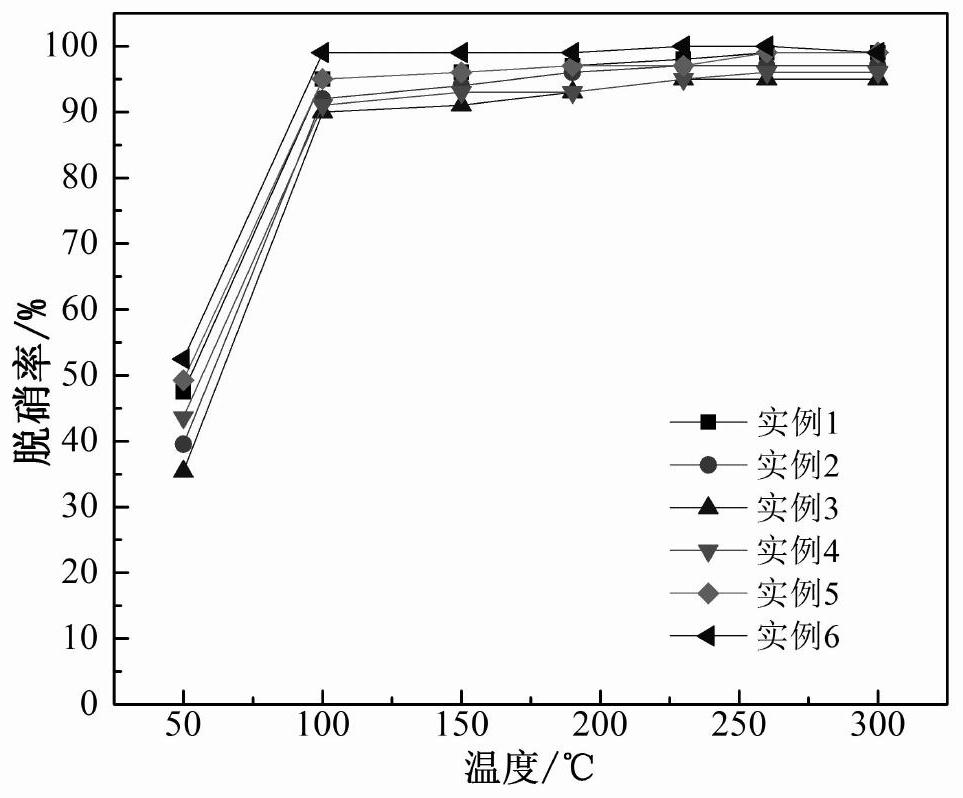

Image

Examples

example 1

[0028] (1) Mixing of main raw materials

[0029] According to formula design, weigh Ni, Mn, Fe, W transition metal oxide mass percentage content is 2%, 10%, 5% and 3% respectively, K, Ba, Ca alkali / alkaline earth metal oxide mass percentage content 10%, 10% and 50% of the active component powder, and the carrier powder with a mass percentage of silicon-aluminum composite oxide of 8% and a mass percentage of activated carbon of 1%, are placed in the mixer Dry mix for 1 hour at a speed of 150 rpm, and stir evenly;

[0030] (2) Wet practice mud

[0031] Put the powder mixed in step (1) into the mud refining machine, then add sodium silicate with a mass percentage of 1% according to the metering ratio, and add deionized water with a total mass of 65% of the denitrification agent, at a speed of 20 Stir and knead for 4 hours under rpm, and finally knead into mud suitable for extrusion;

[0032] (3) Body preparation

[0033] Put the mud after mixing in step (2) into a molding mac...

example 2

[0039] (1) Mixing of main raw materials

[0040] According to formula design, take by weighing Zn, Cu, W, Mo transition metal oxide mass percentage content is respectively 5%, 10%, 4% and 1%, Na, Mg alkali / alkaline earth metal oxide mass percentage content are respectively 40% and 10% of the active component powder, and the silicon-aluminum composite oxide mass percentage content is 15%, the carrier powder with a porous molecular sieve mass percentage content of 5%, is placed in a mixer at a speed of 70 Dry mix for 4 hours at rpm, stir evenly;

[0041] (2) Wet practice mud

[0042] Put the powder mixed in step (1) into the mud refining machine, and then add colloidal silicon dioxide with a mass percentage of 5% and sodium silicate with a mass percentage of 5% according to the metering ratio, and add the denitration agent as a whole Deionized water with a mass of 45% was stirred and kneaded for 1 hour at a speed of 40 rpm, and finally kneaded into a slurry suitable for extrus...

example 3

[0050] (1) Mixing of main raw materials

[0051] According to formula design, weigh Ce, Mn, Cu, Mo transition metal oxide mass percentage content is respectively 1%, 3%, 5% and 1%, Na, Ca alkali / alkaline earth metal oxide mass percentage content is respectively 10% and 10% active component powders, and silicon-aluminum composite oxide mass percentage content is 50%, activated carbon mass percentage content is 2%, porous molecular sieve mass percentage content is 10% carrier powder, put Put it into the mixer and dry mix it for 2 hours at a speed of 120 rpm, and stir evenly;

[0052] (2) Wet practice mud

[0053] Put the powder mixed in step (1) into the mud refining machine, and then add colloidal silicon dioxide with a mass percentage of 1% and sodium silicate with a mass percentage of 4% according to the metering ratio, and add a denitration agent as a whole Deionized water with a mass of 50% was stirred and kneaded for 2 hours at a speed of 30 rpm, and finally kneaded into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com