Aerogel felt loaded layered solid electrolyte of lithium battery and preparation method

A solid electrolyte and aerogel felt technology, which is applied in the manufacture of electrolyte batteries, electrolytes, composite electrolytes, etc., can solve problems such as easy water degradation and battery performance degradation, and achieve the effect of simple process and high lithium ion conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

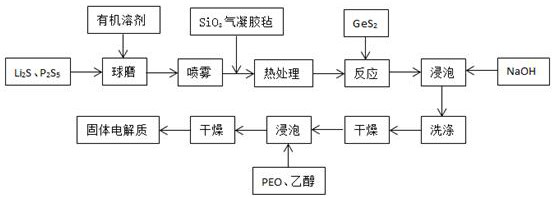

[0030] Example 1 A preparation method of an airgel felt-supported layered solid electrolyte for a lithium battery

[0031] a. Will Li 2 S and P 2 S 5 Mix according to the molar ratio of 4:1, add the organic solvent tetrahydrofuran and ball mill evenly to obtain a ball mill slurry with a mass concentration of 5%;

[0032] b. After the ball mill slurry is atomized through the atomizing nozzle, the carrier gas is used to load the inside of the reaction chamber, and the silica airgel felt is used as the substrate to perform plasma heat treatment at 550°C; after 1 hour of reaction, the carrier gas is used to Load GeS 2 Powder, the loading amount of the ball mill slurry is controlled to be 50% of the mass of the silica airgel felt, GeS 2 The powder loading amount is 5% of the mass of the silica airgel felt, and then stop feeding the ball mill slurry and GeS 2 powder. The plasma gas source is hydrogen, ball mill slurry and GeS 2 The carrier gas of the powder is argon, the flow...

Embodiment 2

[0034] Example 2 A preparation method of an airgel felt-supported layered solid electrolyte for a lithium battery

[0035] a. Will Li 2 S and P 2 S 5 Mix according to the molar ratio of 4:1, add the organic solvent tetrahydrofuran and ball mill evenly to obtain a ball mill slurry with a mass concentration of 10%;

[0036] b. After the ball mill slurry is atomized through the atomizing nozzle, the carrier gas is used to load the inside of the reaction chamber, and the silica airgel felt is used as the substrate for plasma heat treatment at 600°C; after 3 hours of reaction, the carrier gas is used to Load GeS 2 Powder, the loading amount of the ball mill slurry is controlled to be 75% of the mass of the silica airgel felt, GeS 2 The powder loading amount is 8% of the mass of the silica airgel felt, and then stop feeding the ball mill slurry and GeS 2 powder. The plasma gas source is hydrogen, ball mill slurry and GeS 2 The carrier gas of the powder is argon, the flow rate...

Embodiment 3

[0038] Example 3 A preparation method of an airgel felt-supported layered solid electrolyte for a lithium battery

[0039] a. Will Li 2 S and P 2 S 5 Mix according to the molar ratio of 4:1, add the organic solvent tetrahydrofuran and ball mill evenly to obtain a ball mill slurry with a mass concentration of 8%;

[0040] b. After the ball mill slurry is atomized through the atomizing nozzle, the carrier gas is used to load the interior of the reaction chamber, and the silica airgel felt is used as the substrate to perform plasma heat treatment at 550°C; after 2 hours of reaction, the carrier gas is used to Load GeS 2 Powder, the loading amount of the ball milling slurry is 65% of the mass of the silica airgel felt, GeS 2 The powder loading amount is 6% of the mass of the silica airgel felt, and then stop feeding the ball mill slurry and GeS 2 powder. The plasma gas source is hydrogen, ball mill slurry and GeS 2 The carrier gas of the powder is argon, the flow rate of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plane area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Plane area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com