Concrete pipe pile and preparation method thereof

A concrete pipe pile and concrete technology, which is applied in the field of concrete pipe piles, can solve the problems of lack of impermeability, impermeability of pipe piles to be improved, coating peeling, etc., so as to improve connectivity, improve temperature resistance, and enhance The effect of impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

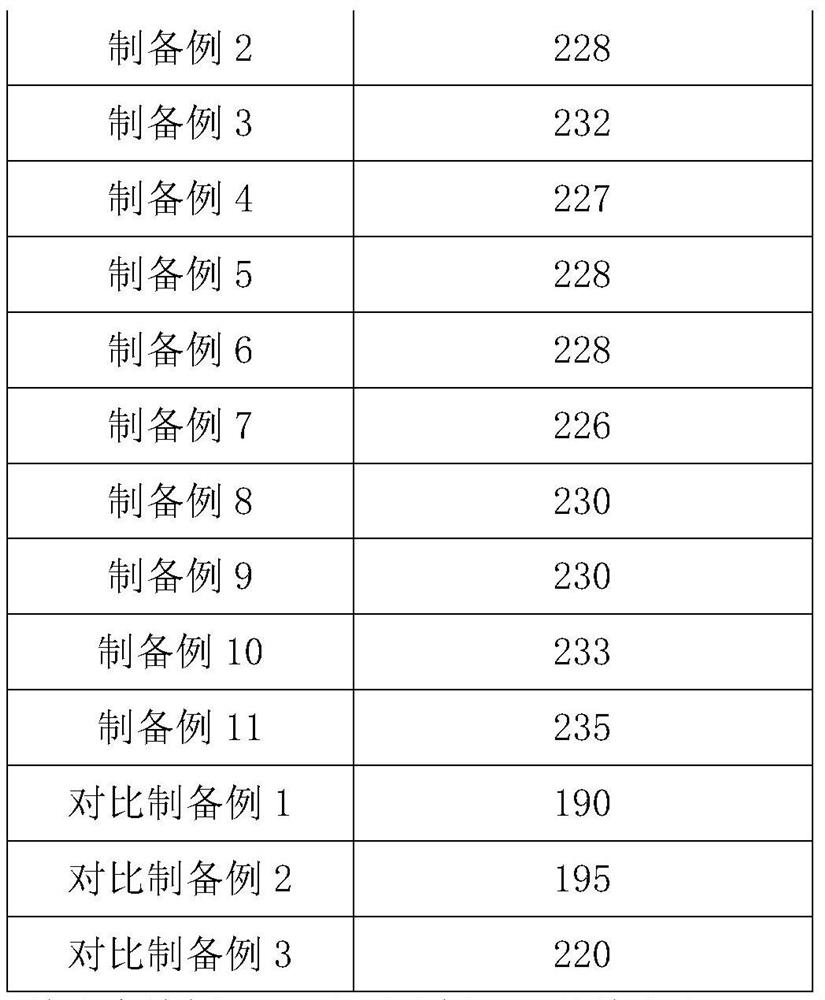

Examples

preparation example 1

[0042] Modified linseed vine fiber, its preparation method is as follows: remove 15kg vine stem from linseed vine, dry after washing with water, pulverize, obtain crude fiber, the length of crude fiber is 5mm, and fineness is 0.5D; Add sodium hydroxide and 0.1kg of surfactant to 60kg of water, the surfactant is sodium lignosulfonate, mix evenly to obtain a treatment solution; put the crude fiber into the treatment solution, raise the temperature to 60°C for 40 minutes, filter, wash with water, and dry Dry to obtain pretreated fibers; mix pretreated fibers, 2kg aromatic acid, 0.1kg esterification catalyst and 90kg ethanol evenly, the aromatic acid is terephthalic acid, the esterification catalyst is sodium hypophosphite, heat up to 90°C, and react for 15min Finally, filter, wash with water, and dry to obtain modified linseed rattan fiber.

preparation example 2

[0044] Modified linseed vine fiber, its preparation method is as follows: remove 20kg vine stem from linseed vine, dry after washing with water, pulverize, obtain crude fiber, the length of crude fiber is 10mm, and fineness is 3D; 1kg hydrogen oxidizes Sodium and 0.15kg of surfactant were added to 70kg of water, the surfactant was sodium dodecylbenzenesulfonate, mixed evenly to obtain a treatment solution; the crude fiber was put into the treatment solution, heated to 70°C for 35min, filtered, washed with water, Dry to obtain pretreated fiber; mix pretreated fiber, 3kg aromatic acid, 0.2kg esterification catalyst and 95kg ethanol evenly, aromatic acid is isophthalic acid, esterification catalyst is disodium hydrogen phosphate, heat up to 95°C, After reacting for 12 minutes, filter, wash with water, and dry to obtain modified linseed rattan fiber.

preparation example 3

[0046] Modified linseed vine fiber, its preparation method is as follows: remove 30kg vine stem from linseed vine, dry after washing with water, pulverize, obtain crude fiber, the length of crude fiber is 20mm, fineness is 5D; 1.5kg hydrogen Sodium oxide and 0.2kg of surfactant were added to 80kg of water, the surfactant was sodium dibutylnaphthalene sulfonate, mixed evenly to obtain a treatment solution; the crude fiber was put into the treatment solution, heated to 80°C for 30 minutes, filtered, washed with water, Dry to obtain the pretreated fiber; mix the pretreated fiber, 4kg aromatic acid, 0.3kg esterification catalyst and 100kg ethanol evenly, the aromatic acid is phthalic acid, the esterification catalyst is sodium phosphate, heat up to 100°C, and react for 10min Finally, filter, wash with water, and dry to obtain modified linseed rattan fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com