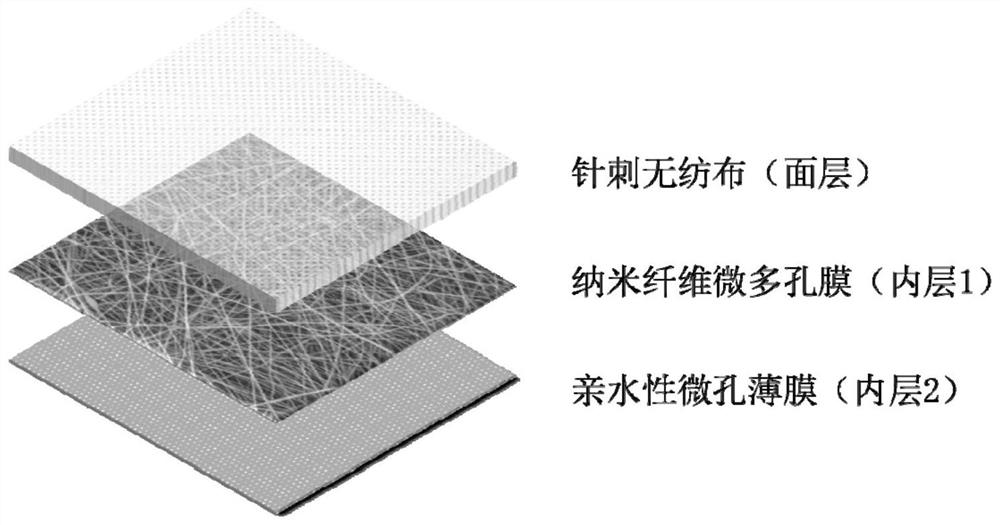

High-efficiency and low-resistance filter membrane and application thereof in mask fabric

A filter membrane and high-efficiency technology, applied in the field of filter materials, can solve the problems of weakening and disappearing of electrostatic adsorption, thick appearance of N95 masks, etc., and achieve the effects of high barrier efficiency, small breathing resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

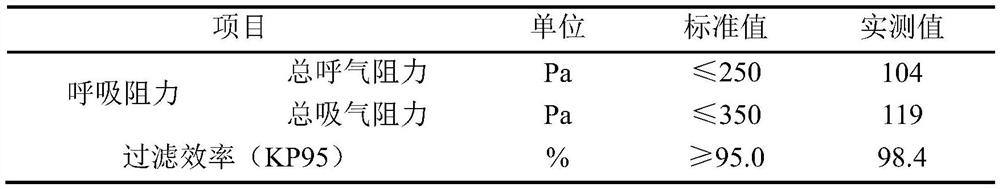

Examples

Embodiment 1

[0016] A preparation method of high-efficiency, low-resistance filter membrane and mask fabric, comprising the following steps:

[0017] Preparation of surface layer non-woven fabric: use low-melting-point crimped polyester staple fibers mixed with ES fibers for needle punching, the needle-punching frequency is 20 Hz, the web speed is 10 m / min, and the proportion of low-melting point polyester staple fibers is 10 wt%. After single-side ironing process, the calendering speed is 20m / min, the temperature is 130°C, and the surface layer needle-punched non-woven fabric is developed, with a grammage of 60g / m 2 .

[0018] Preparation of the inner composite filter membrane: A layer of nanofiber microporous membrane is constructed on the surface of the polyamide 6 microporous film by polyvinyl chloride electrospinning technology, the electrospinning voltage is 10KV, the spinneret distance is 5cm, and the thickness of the electrospun film is controlled to be 0.2 μm, the equivalent pore...

Embodiment 2

[0021] A preparation method of high-efficiency, low-resistance filter membrane and mask fabric, comprising the following steps:

[0022] Preparation of surface layer non-woven fabric: low-melting-point curly polyester staple fibers mixed with ES fibers were used for needle punching at a needle-punching frequency of 20 Hz and a web speed of 10 m / min, in which low-melting point polyester staple fibers accounted for 14 wt%. After single-side ironing process, the calendering speed is 20m / min, the temperature is 135°C, and the surface layer needle-punched non-woven fabric is developed, with a grammage of 65g / m 2 .

[0023] Preparation of the inner composite filter membrane: construct a nanofiber microporous membrane on the surface of the polyamide 66 microporous membrane by electrospinning polystyrene, the electrospinning voltage is 10KV, the spinneret distance is 6cm, and the thickness of the electrospun membrane is controlled to be 0.25μm , the equivalent pore diameter is 0.2μm,...

Embodiment 3

[0026] A preparation method of high-efficiency, low-resistance filter membrane and mask fabric, comprising the following steps:

[0027] Preparation of surface layer non-woven fabric: use low-melting point curly polyester staple fiber mixed with ES fiber for needle punching, acupuncture frequency 25Hz, web speed 15m / min, in which low melting point polyester staple fiber accounts for 18wt%. After single-sided ironing process, the calendering speed is 25m / min, the temperature is 135°C, and the surface layer needle-punched non-woven fabric is developed, with a grammage of 70g / m 2 .

[0028] Preparation of the inner layer composite filter membrane: A layer of nanofiber microporous membrane is constructed on the surface of the polyacrylonitrile microporous membrane by polyvinyl chloride electrospinning technology, the electrospinning voltage is 15KV, the spinneret distance is 7cm, and the thickness of the electrospun membrane is controlled to be 0.5 μm, the equivalent pore diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com